A kind of rosin-based polyamine conductive epoxy curing agent and its preparation method and application

A conductive ring and curing agent technology, used in conductive adhesives, epoxy resin adhesives, adhesives, etc., can solve the problems of high price and high conductive percolation threshold of conductive adhesives, achieve less waste, reduce conductive percolation thresholds, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

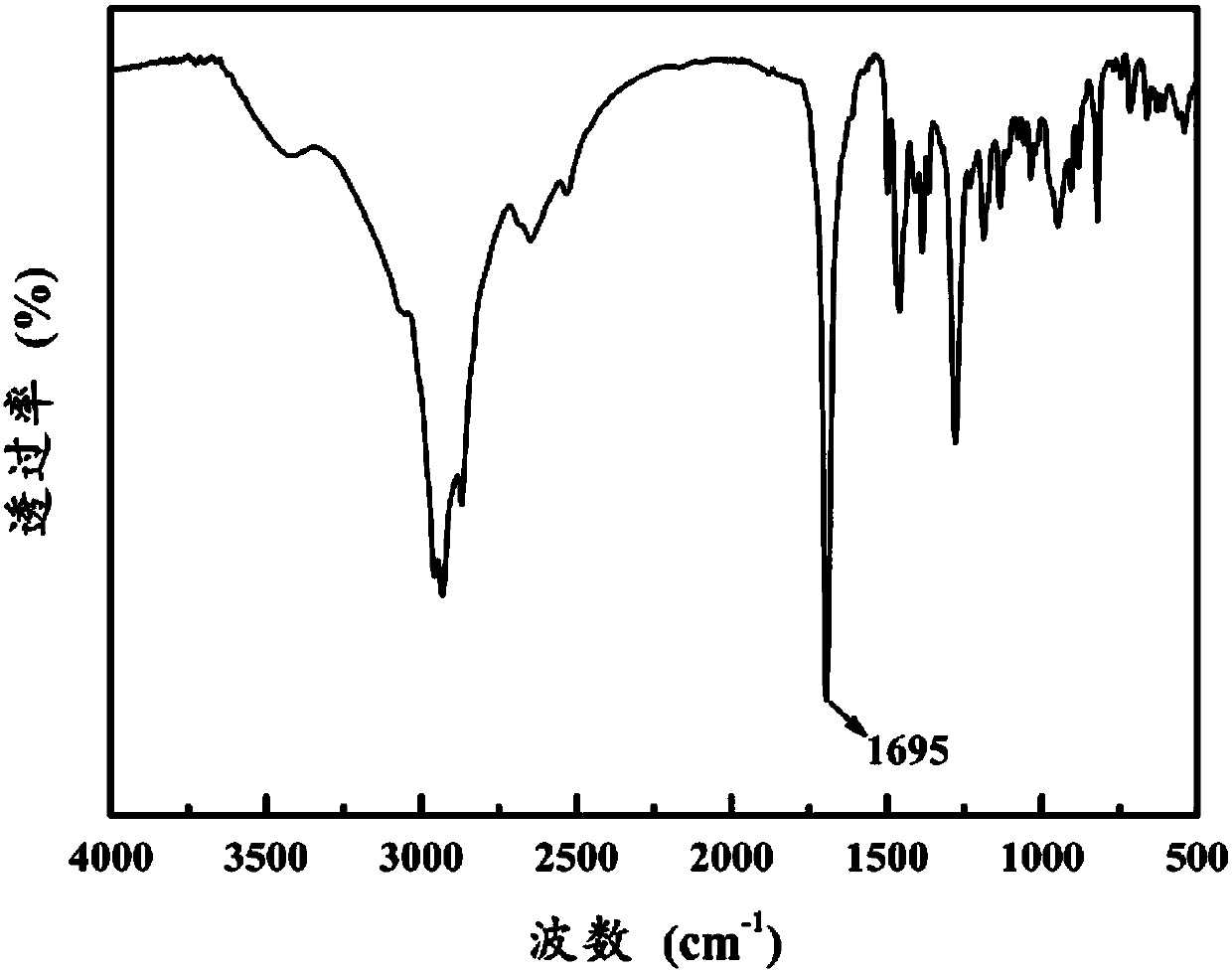

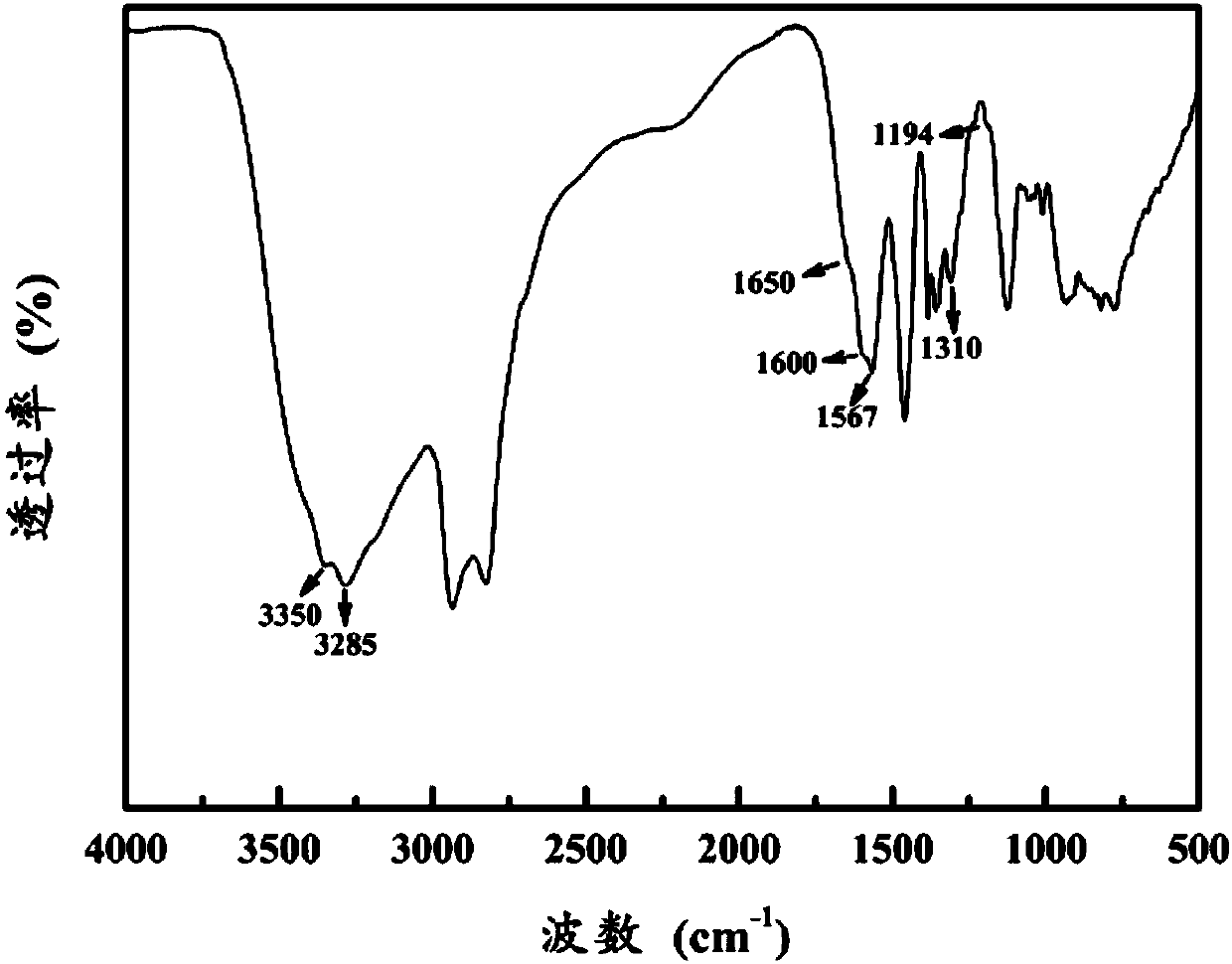

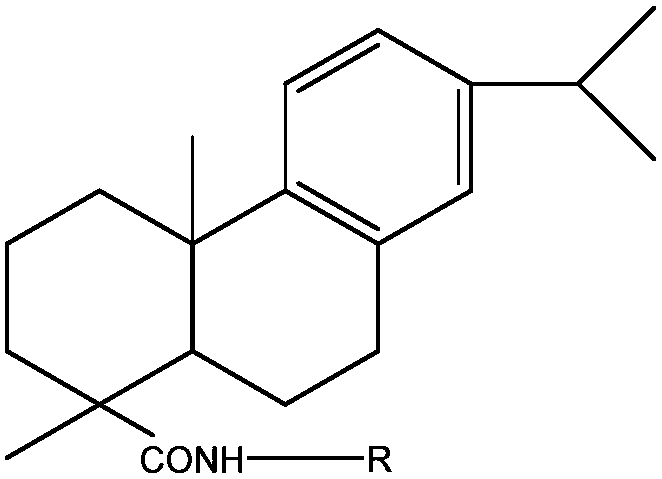

[0028] The purified product of disproportionated rosin, dehydroabietic acid, reacts with tetraethylenepentamine (the molar ratio of dehydroabietic acid to tetraethylenepentamine is 1:4) at 200°C for 3 hours, and removes excess tetraethylene by distillation under reduced pressure. Pentaamine, to obtain a reddish transparent liquid rosin-based polyamine, the structural formula of which is shown in the following formula.

[0029]

[0030] Rosin-based polyamine and graphene are mixed at 1000 rpm (the mass ratio of rosin-based polyamine to graphene is 24:1), and the mixing time is 15min to obtain a black liquid rosin-based polyamine conductive epoxy resin curing agent. Its amine value is 850mgKOH / g, and its conductivity is 4.5S / cm.

[0031] Epoxy resin and rosin-based polyamine conductive epoxy resin curing agent are mixed at a mass ratio of 4:1, and adding 15wt.% silver powder can make the conductivity of epoxy resin reach 4.8×104 S / cm.

Embodiment 2

[0033] The purified product of disproportionated rosin, dehydroabietic acid, was reacted with triethylenetetramine (the molar ratio of dehydroabietic acid to triethylenetetramine was 1:5) at 220°C for 4 hours, and the excess triethylenetetramine was removed by distillation under reduced pressure. Tetramine, the rosin-based polyamine of reddish transparent liquid state is obtained, and its structural formula is as shown in the following formula.

[0034]

[0035] Rosin-based polyamine and carbon nanotubes were mixed at 800 rpm (the mass ratio of rosin-based polyamine to carbon nanotubes was 19:1), and the mixing time was 30 minutes to obtain a black liquid rosin-based polyamine conductive epoxy resin for curing agent, its amine value is 780mgKOH / g, and its conductivity is 4.1S / cm.

[0036] Epoxy resin and rosin-based polyamine conductive epoxy resin curing agent are mixed at a mass ratio of 4:1, and then adding 15wt.% silver powder can make the conductivity of epoxy resin re...

Embodiment 3

[0038] The purified product of disproportionated rosin, dehydroabietic acid, was reacted with diethylenetriamine (the molar ratio of dehydroabietic acid to diethylenetriamine was 1:3) at 200°C for 6 hours, and the excess diethylene was removed by distillation under reduced pressure. triamine, to obtain a reddish transparent liquid rosin-based polyamine, the structural formula of which is shown in the following formula.

[0039]

[0040] Rosin-based polyamine and conductive carbon black were mixed at 1600 rpm (the mass ratio of rosin-based polyamine to conductive carbon black was 3:2), and the mixing time was 30 minutes to obtain a black liquid rosin-based polyamine conductive epoxy resin for curing agent, its amine value is 660mgKOH / g, and its conductivity is 3.4S / cm.

[0041] Epoxy resin and rosin-based polyamine conductive epoxy resin curing agent are mixed in a mass ratio of 4:1, and then adding 35wt.% silver powder can make the conductivity of epoxy resin reach 3.2×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com