Preparation method of light heat-insulating mullite nanofiber aerogel

A nanofiber, lightweight heat insulation technology, applied in the direction of ceramic products, applications, home appliances, etc., can solve the problem of improving heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

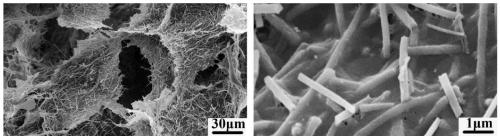

[0025] (1) Cut the mullite nanofiber membrane to 10mm with scissors 2 Size, weigh 0.2g of fiber film and add it to 50ml of ethanol, disperse it with a high-speed disperser at 3000r / min for 5min, take out the suspension above it and dry it to obtain a single fiber.

[0026] (2) Take 5g tetraethyl orthosilicate, 3g ethanol, 2g deionized water, drop 3 drops of 0.1mol / L dilute nitric acid therein, magnetic stirring makes the solution clear and transparent to obtain 50wt% silica sol; weigh 0.08g Put the silica sol into the mold, add 1.92g of water, 0.1g of acrylamide, 0.005g of N-N methylenebisacrylamide, stir well to dissolve it.

[0027] (3) Add 0.05g fiber to the mold, stir to disperse evenly, then add 3 drops of ammonium persulfate aqueous solution, 1 drop of tetramethylethylenediamine aqueous solution, seal and keep warm at 50°C for 20min to make it gel .

[0028] (4) Put the gelled sample into an ultra-low temperature freezer to freeze at -80°C for 24 hours, take it out and...

Embodiment 2

[0030] (1) Cut the mullite nanofiber membrane to 10mm with scissors 2 Size, weigh 0.2g of fiber film and add it to 50ml of ethanol, disperse it with a high-speed disperser at 3000r / min for 5min, take out the suspension above it and dry it to obtain a single fiber.

[0031] (2) Take 5g tetraethyl orthosilicate, 3g ethanol, 2g deionized water, drop 3 drops of 0.1mol / L dilute nitric acid therein, magnetic stirring makes the solution clear and transparent to obtain 50wt% silica sol; weigh 0.08g Put the silica sol into the mold, add 1.92g of water, 0.1g of acrylamide, 0.005g of N-N methylenebisacrylamide, stir well to dissolve it.

[0032] (3) Add 0.05g fiber to the mold, stir to disperse evenly, then add 3 drops of ammonium persulfate aqueous solution, 1 drop of tetramethylethylenediamine aqueous solution, seal and keep warm at 50°C for 20min to make it gel .

[0033] (4) Put the gelled sample into an ultra-low temperature freezer to freeze at -80°C for 24 hours, take it out and...

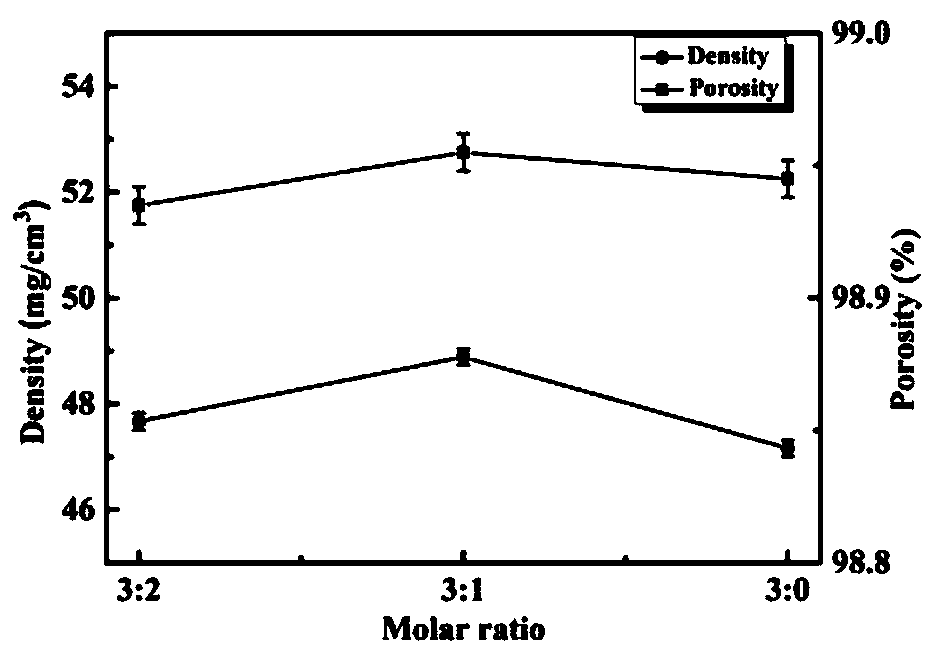

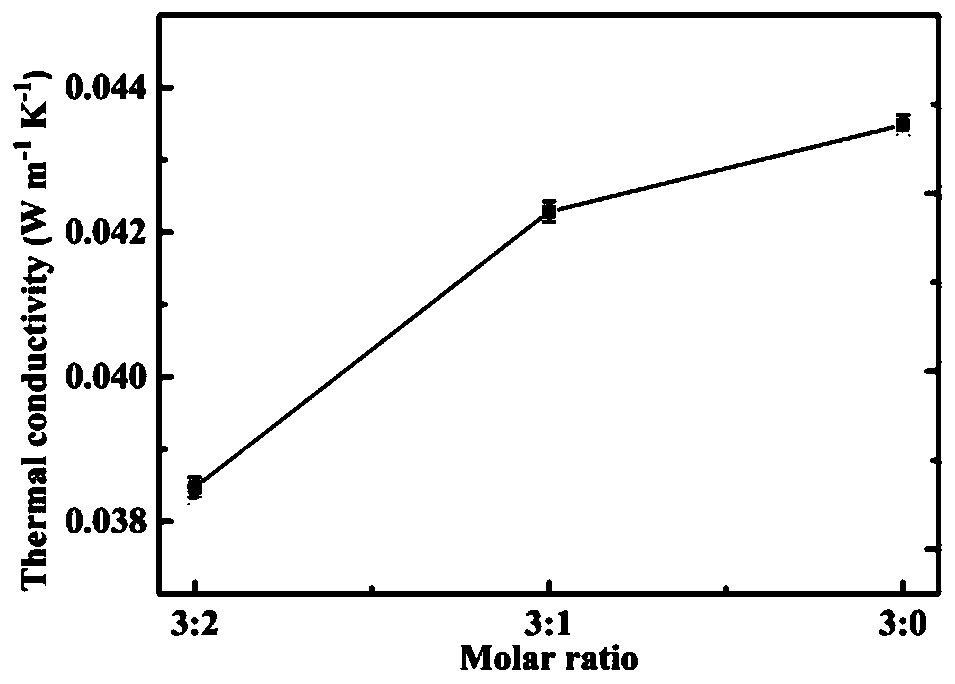

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com