Ultrasonic grinding device for gear

An ultrasonic and grinding technology, used in gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of complex gear grinding process, achieve good economic benefits, prevent dust from entering, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

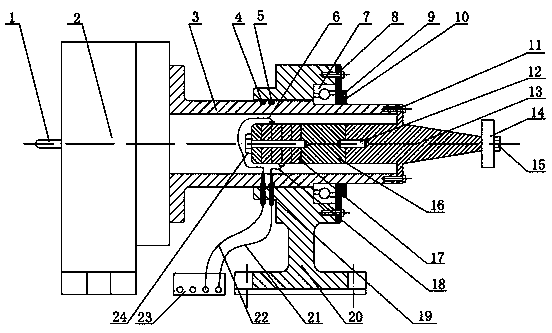

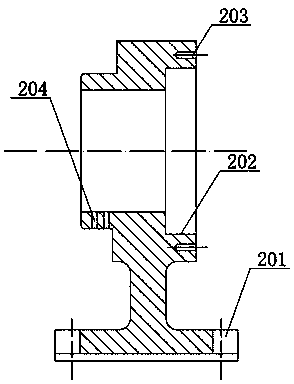

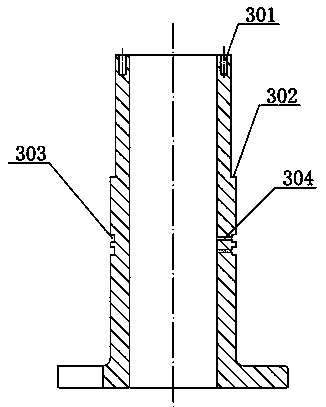

[0028] Embodiment one: see Figure 1-Figure 4 , in the figure, 1-handle, 2-rotary indexing device, 3-rotary hollow shaft, 4-rubber sleeve, 5-conductive copper ring, 6-first wire, 7-angular contact bearing, 8-connecting bolt, 9 -Bearing end cover, 10-Felt ring oil seal, 11-Screw, 12-Stud bolt, 13-Amplifier, 14-Gear workpiece, 15-Lock nut, 16-Vibrating rod, 17-Piezoelectric ceramic sheet , 18-second wire, 19-electric brush, 20-fixed base, 21-second connecting wire, 22-first connecting wire, 23-ultrasonic generator, 24-connecting bolt, 201-U-shaped groove, 202- Bearing groove, 203-threaded hole, 204-electric brush hole, 301-threaded hole, 302-shaft shoulder, 303-groove, 304-threading hole.

[0029] The fixed base 20 of the gear ultrasonic grinding device is provided with two U-shaped grooves 201 to connect with the workbench, the base of the fixed base 20 is provided with a groove 202 for fixing the bearing, and the right end surface of the fixed base 20 is provided along the ci...

Embodiment 2

[0034] Embodiment two: see Figure 5 , Figure 7-Figure 9, 1-handle, 2-rotary indexing device, 3-rotary hollow shaft, 9-angular contact bearing, 10-connecting bolt, 11-bearing end cover, 12-felt ring oil seal, 13-connecting bolt, 14-double head Bolt, 15-horn, 16-gear workpiece, 17-lock nut, 18-vibration rod, 19-piezoelectric ceramic sheet, 20-wire, 21-fixed base, 22-connecting line, 23-ultrasonic generator Device, 24-connecting bolts, 34-fixing bolts, 35-outer aluminum disc seat, 36-outer coil disc, 37-inner coil disc, 38-inner aluminum disc seat, 201-U-shaped groove, 202-bearing groove, 203-threaded hole, 205-aluminum disc hole, 301-bolt hole, 302-positioning step, 305-threading hole, 306-threaded hole.

[0035] The gear ultrasonic grinding device is composed of a fixed base, a gear workpiece rotation system, an ultrasonic vibration system, an external support fixing system and an ultrasonic power supply. The bottom of the fixed base 20 is provided with two U-shaped groove...

Embodiment 3

[0041] Embodiment three: see Figure 6 , in the figure, 25-variable frequency motor, 26-connecting plate, 27-motor flange, 28-fixed flange, this embodiment is basically the same as Embodiment 1, the similarities will not be repeated, the difference lies in: rotation One end of the hollow shaft 3 is connected with the fixed flange, and the output shaft of the variable frequency motor 25 is connected with the motor flange through a key, and the motor flange is connected with the fixed flange through connecting bolts.

[0042] Driven by the frequency conversion motor 25 to rotate at high speed, it is suitable for precision grinding of the outer circle of disc or cylindrical gear workpieces; by adjusting the frequency conversion motor 25 to change the rotation speed of disc or cylindrical workpieces 16, the grinding of discs or cylindrical workpieces can be realized. Or precision grinding of the outer circle of cylindrical gear workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com