Method for regulating and controlling microstructure of oxide electrode in working period of fuel cell

A fuel cell and microscopic morphology technology, applied in the direction of fuel cell control, battery electrodes, fuel cell additives, etc., can solve problems such as unfavorable electrode reaction process, waste of material and manpower, particle agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

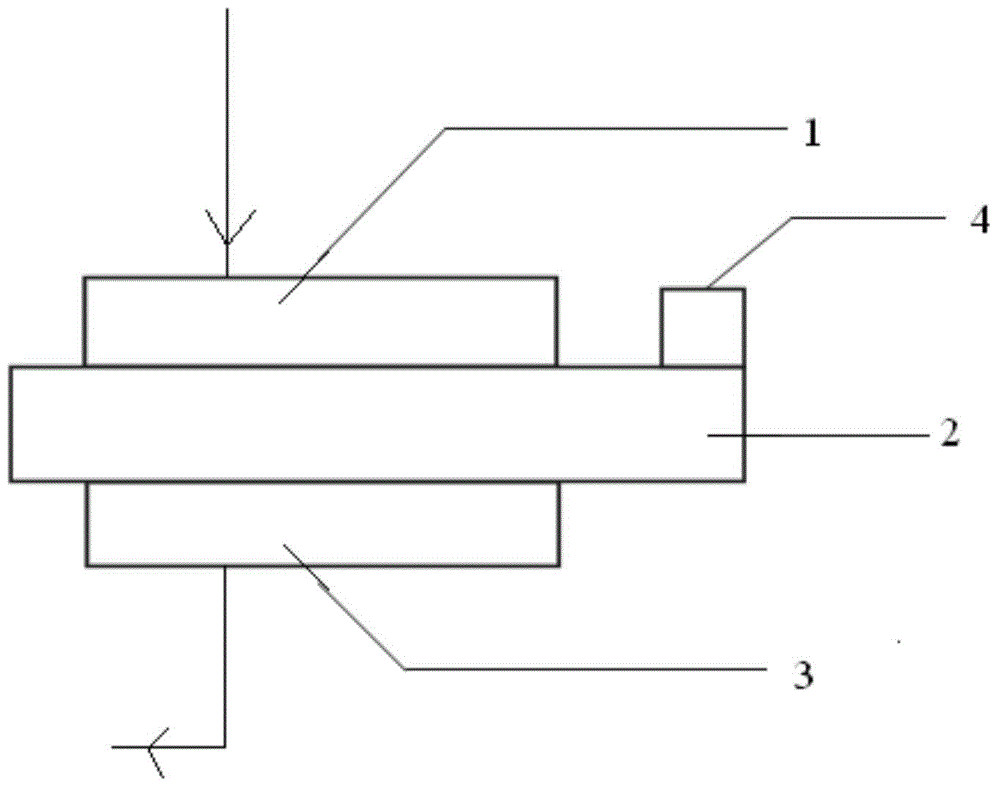

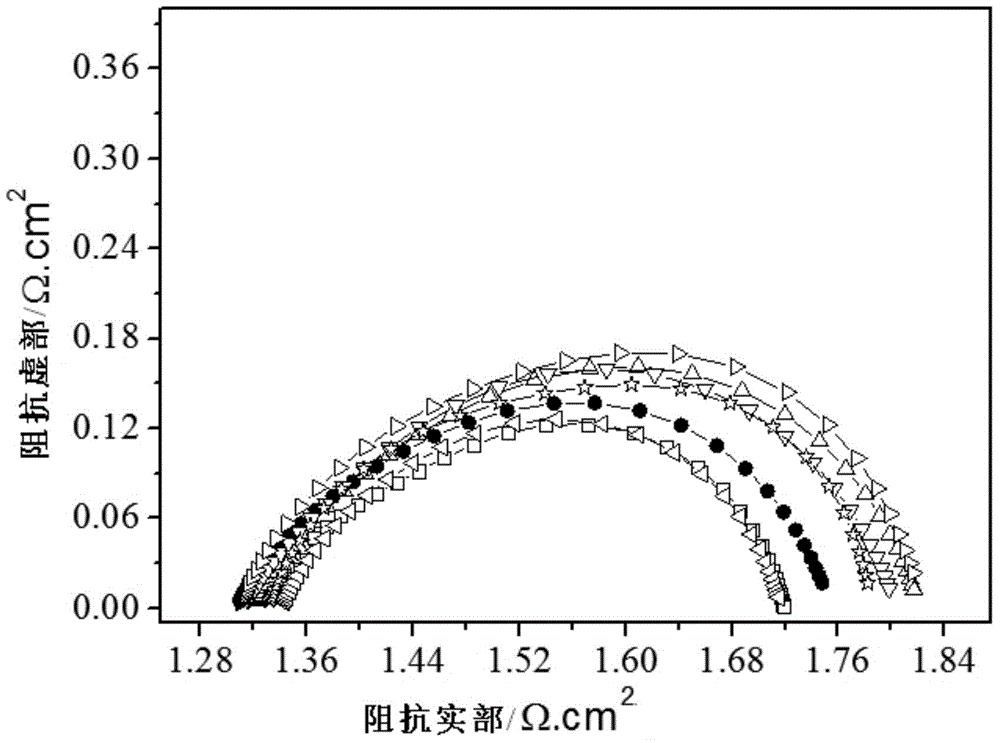

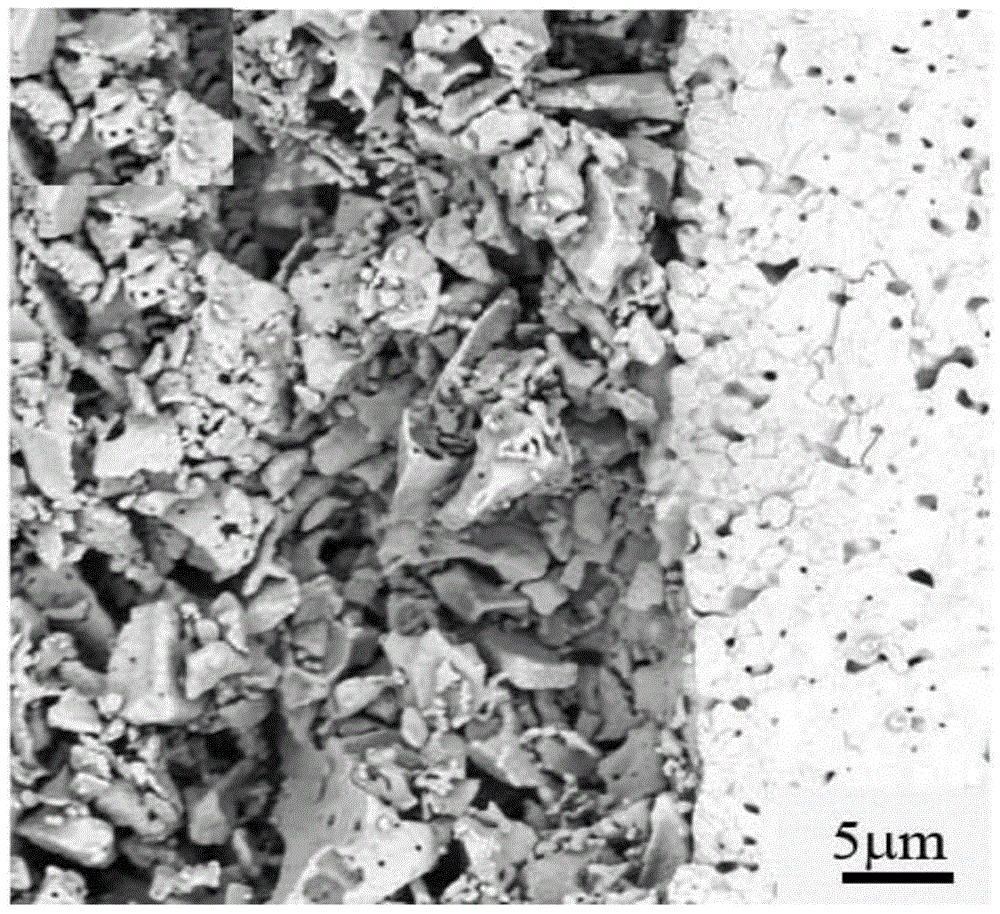

[0013] Specific implementation mode 1: This implementation mode is a method for regulating the microscopic morphology of oxide electrodes during the operation of the fuel cell, which is specifically carried out according to the following steps:

[0014] 1. Coating the conductive silver paste to the oxide working electrode of the fuel cell, the reference electrode of the fuel cell and the counter electrode of the fuel cell, and then coating the oxide working electrode of the fuel cell, the reference electrode of the fuel cell and the fuel Lead out a wire from the conductive silver paste on the counter electrode of the battery, put it into a muffle furnace and dry it for 5min to 10min at a temperature of 80°C to 200°C, and connect the three wires drawn out from the conductive silver paste Connect to the corresponding terminal of the electrochemical workstation, and then increase the temperature in the muffle furnace from 80°C to 200°C to 400°C to 1000°C within 0.5h to 2.5h, and t...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the oxide working electrode of the fuel cell described in step 1 has ABO 3 Perovskite structure oxides of general formula or with A 2 BO 4 A perovskite-like structure oxide of the general formula. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the chemical formula of the perovskite structure oxide with ABO3 general formula described in step one is CDO 3 、CD 1-x E. x o 3 、C 1-x f x do 3 or C 1-x f x D. 1-y E. y o 3 ; where CD 1-x E. x o 3 、CDO 3 、C 1-x f x do 3 and C 1-x f x D. 1-y E. y o 3C is a rare earth element, C is specifically La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu or Y, F is an alkaline earth element, and F is specifically Ca, Sr Or Ba, D is a 3d transition group metal element, D is specifically Ti, V, Cr, Mn, Fe, Co, Ni or Cu, E is a 3d transition group metal element, and E is specifically Ti, V, Cr, Mn, Fe , Co, Ni or Cu, O is oxygen element; CD 1-x E. x o 3 Medium 01-x f x do 3 Medium 01-x f x D. 1-y E. y o 3 In 0<x<1, 0<y<1. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com