Preparation method of compact composite coating layer based on reactive plasma spraying and laser remelting

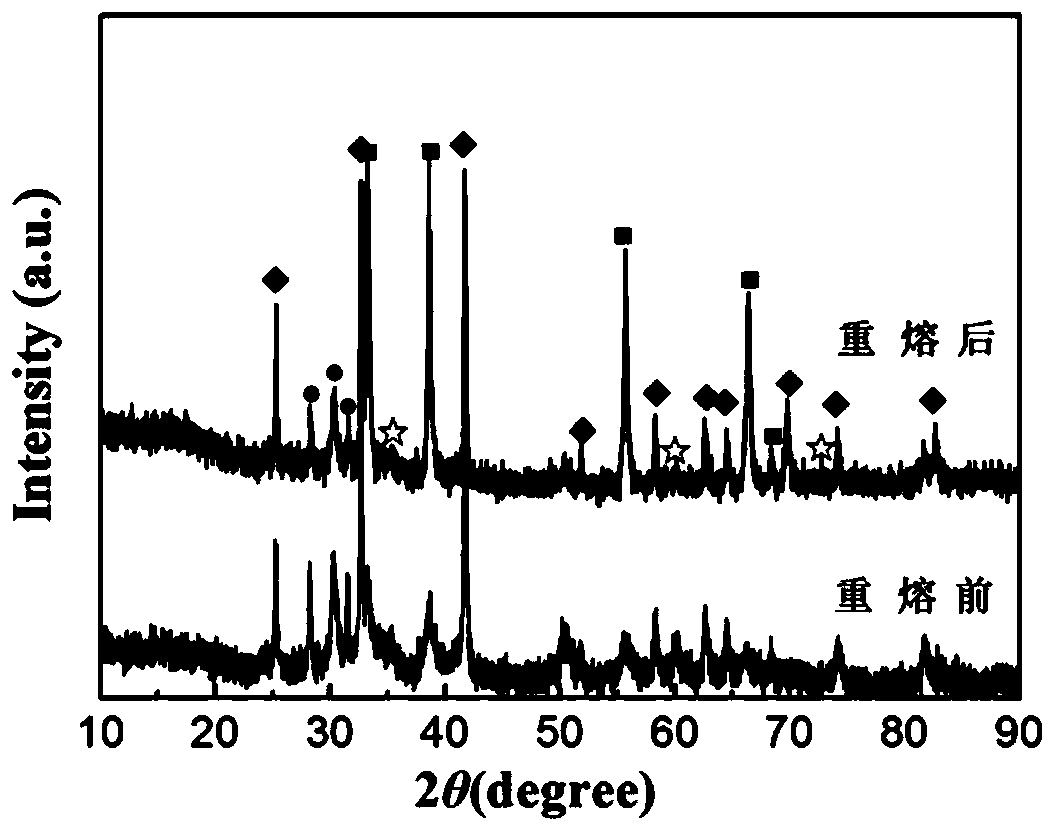

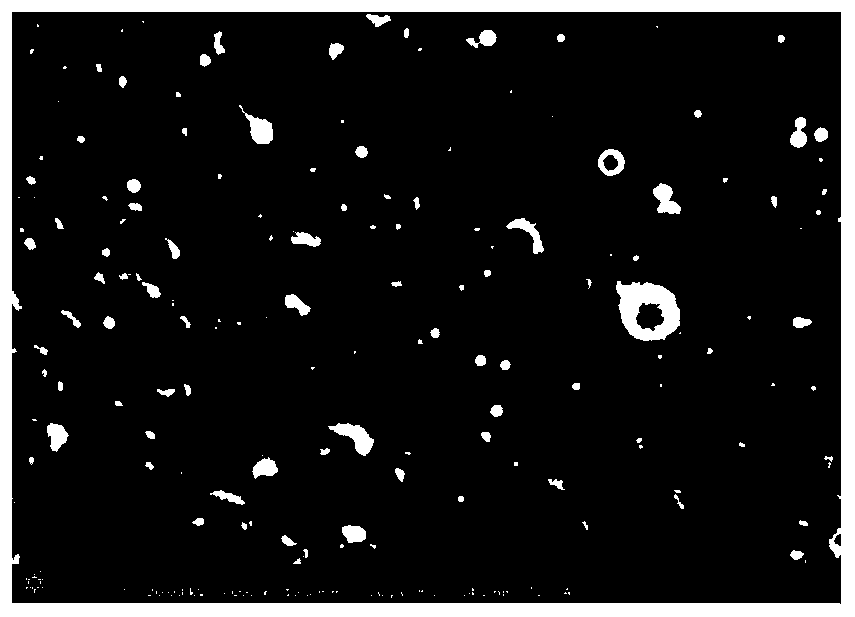

A technology of laser remelting and composite coating, which is applied in the field of surface treatment to achieve the effect of improving microscopic appearance, reducing coating cracking tendency and improving coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific Embodiment One: The preparation method of the dense composite coating based on reactive plasma spraying and laser remelting in this embodiment includes the following steps:

[0035] Step 1. Prepare spray powder:

[0036] The powder, deionized water, ammonium citrate and gum arabic are ball milled and mixed to obtain a slurry, which is sprayed and granulated to obtain a mixed spray powder; the powder includes zirconium powder (Zr), boron carbide powder (B 4 C) and silicon powder (Si);

[0037] Step 2, pretreatment of matrix material:

[0038] Sandblasting the surface of the ZrC-SiC substrate, then cleaning the ZrC-SiC substrate with absolute ethanol in an ultrasonic cleaner, and drying to obtain a pretreated ZrC-SiC substrate;

[0039] The ZrC-SiC matrix is prepared by a hot-press sintering method: ZrC powder and SiC powder are ball-milled and mixed, and then prepared by vacuum hot-press sintering;

[0040] Step 3. Prepare the coating using RPS technology: ...

specific Embodiment approach 2

[0047] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the molar ratio of zirconium powder, boron carbide powder and silicon powder in the powder in step 1 is 1:0.456:0.368. Others are the same as in the first embodiment.

[0048] The final product ZrB that adopts the ratio generation of present embodiment 2 - SiC in SiC-ZrC is 20vol.%. At this time, the high temperature performance of the material is better.

specific Embodiment approach 3

[0049] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, the mass ratio of powder, deionized water, ammonium citrate and gum arabic is 1:(1.5~2):(0.4~0.8) : (1~2). Others are the same as in the first embodiment.

[0050] Selecting the mass ratio of this embodiment can give the slurry reasonable viscosity and fluidity, and ensure the smooth completion of spray granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com