Self-standing TiO2 nanotube array membrane and preparation method thereof

A nanotube array, self-supporting technology, applied in photosensitive equipment, semiconductor/solid-state device manufacturing, electrolytic capacitors, etc., can solve the problems of small potential application, curling into groups, and unrealizable research fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

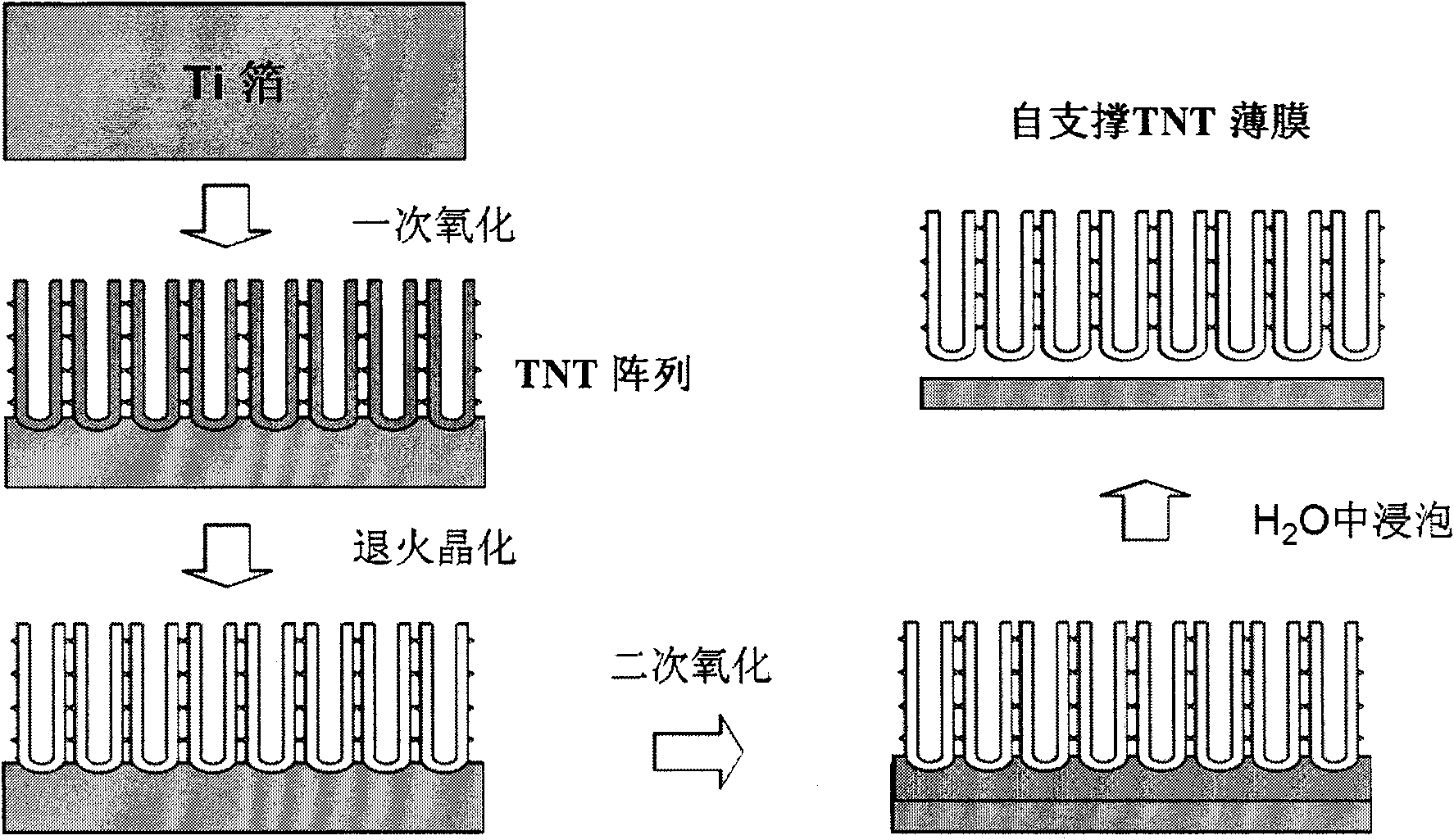

Method used

Image

Examples

Embodiment 1

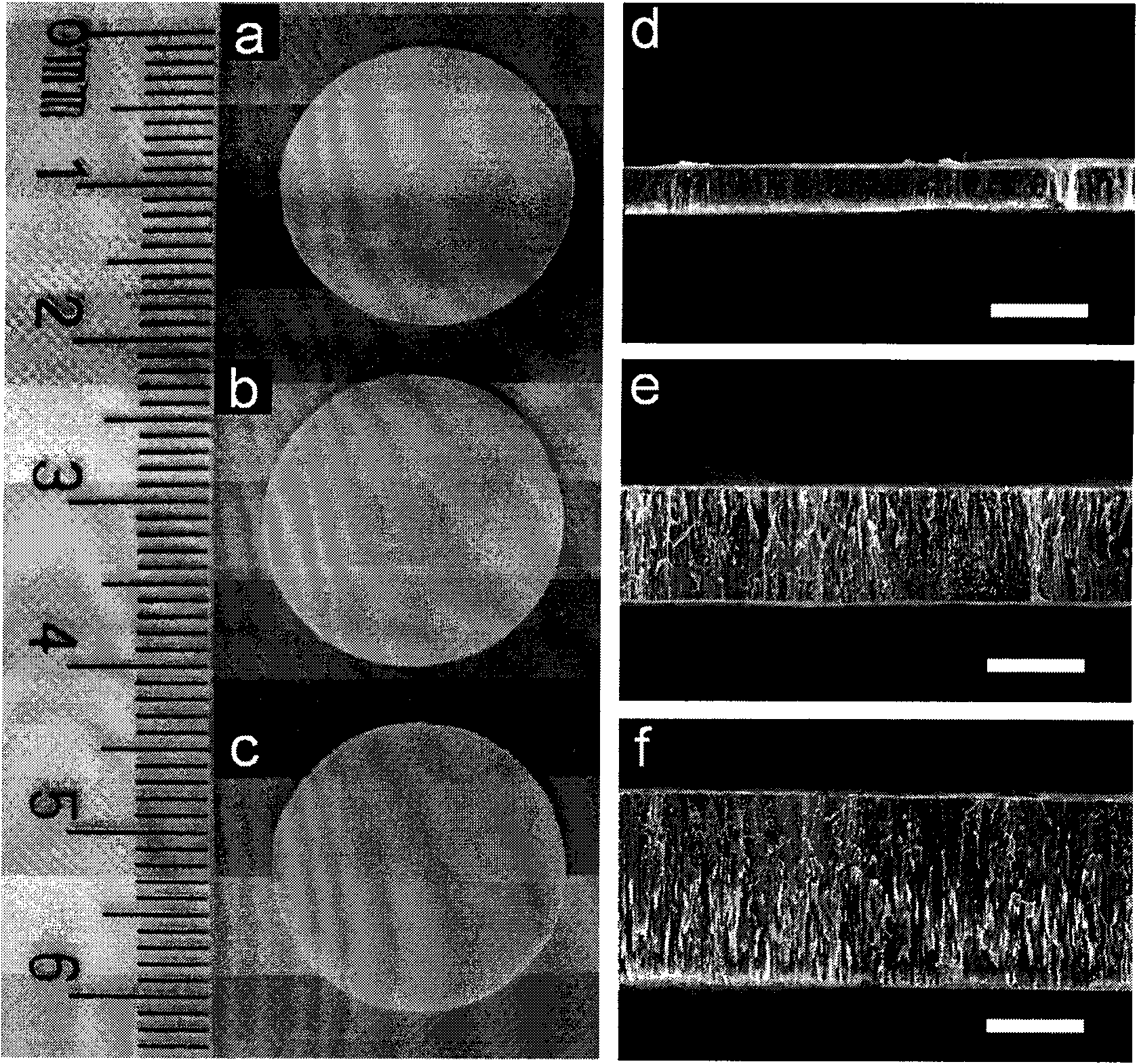

[0058] At room temperature, place a titanium sheet (15×30mm) with PTFE tape on the back and edges in 20mL containing 0.25wt%NH 4 F, 1wt%H 2 In the ethylene glycol solution of O, the anodic oxidation was carried out under the bias voltage of 30V for 72h, and the thickness of the obtained TNT film was 9 μm. After the oxidation was completed, the titanium sheet with the TNT film was taken out, placed in an ethanol solution for ultrasonic cleaning twice, and then transferred to an open tube furnace for annealing at 350 °C for 1 h at a heating rate of 5 °C / min. The annealed sample is again placed in fresh ethylene glycol electrolyte for anodic oxidation, the voltage is 12V, and the oxidation time is 3h, which is the secondary anodic oxidation, and the formed amorphous TiO 2 The thickness of the oxide layer is 300nm. After the secondary anodic oxidation is finished, take the sample out, first wash it with ethanol (analytical grade), then place it in a petri dish, and gradually add...

Embodiment 2

[0060] At room temperature, place a titanium sheet (15 × 30 mm) covered with PTFE tape on the back and edges in 20 mL of 0.25 wt% NH 4 F, 1wt%H 2 In the ethylene glycol solution of O, the anodic oxidation was carried out under 50V bias for 24h, and the thickness of the obtained TNT film layer was 25μm. After the oxidation was completed, the titanium sheet with the TNT film was taken out, placed in an ethanol solution for ultrasonic cleaning twice, and then transferred to an open tube furnace for annealing at 350 °C for 1 h at a heating rate of 5 °C / min. The annealed sample was again placed in the same ethylene glycol electrolyte as the primary oxidation for secondary anodic oxidation, the voltage was 15V, and the oxidation time was 1h, the formed TiO 2 The thickness of the oxide layer is 200nm. After the secondary anodic oxidation is completed, the sample is taken out, rinsed with ethanol first, and then placed in a petri dish, and deionized water is gradually added. With th...

Embodiment 3

[0063] A TNT film with a thickness of 42 μm (oxidized at 50 V in ethylene glycol system for 48 h, the preparation conditions are the same as in Example 1) was placed in a tube furnace for annealing at 500° C. for 1 h, and the heating rate was 5° C. / min. After cooling, place the sample again in fresh ethylene glycol electrolyte for secondary anodic oxidation, the voltage is 15V, the oxidation time is 30min, the formed TiO 2 The thickness of the oxide layer is 100 nm. After the secondary anodic oxidation, the sample was taken out, rinsed with ethanol first, then placed in a petri dish, and gradually added to deionized water for soaking. The edge of the film was not obviously separated from the substrate. At this point, remove the aqueous solution and add 10ml of 1M HNO to the Petri dish 3 solution. After soaking for about 1 hour, the solution turns light yellow, and the edge of the TNT film is separated from the substrate, becoming a self-supporting film. The film was soaked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com