A kind of method for preparing INP film material

A technology of thin film materials and solid materials, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of complex preparation process, large environmental pollution, high cost, etc., and achieve simple preparation process and simple raw materials , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

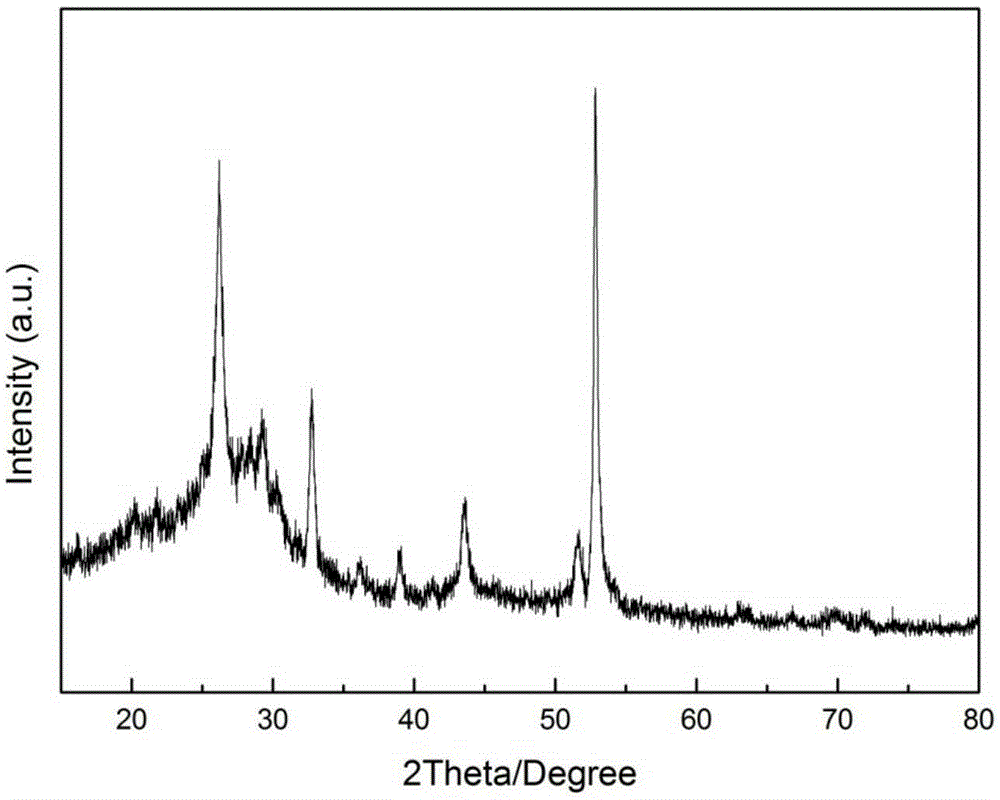

Embodiment 1

[0026] Step 1. Accurately weigh In with a ten-thousandth electronic balance 2 o 3 , P 2 o 5 , according to the ratio of molar ratio In:P=1.0:1.0~1.5, mix and grind evenly, add anhydrous ethanol equivalent to 50%~100% of the mass of solid raw materials, grind again carefully, remove the solvent by drying, and use 10~15MPa Press it into a disc with a thickness of 3mm, then seal it in a vacuum ampoule, place the ampoule in the corundum crucible of the reactor, and heat it to 500°C to 600°C in a self-made tube electric furnace. Constant temperature for 2 to 4 hours, natural cooling, that is, InPO 4 solid material;

[0027] Step 2. Break the ampoule, put the InPO 4 The solid material is placed in the reaction zone of the vertical gradient condensation thin film deposition device, and replaced by high-purity nitrogen to the oxygen concentration at the ppm level, and then Ar+H 2 Mixed gas (containing H 2 The volume percentage is 10% to 30%) vacuuming and replacing 1 to 2 times...

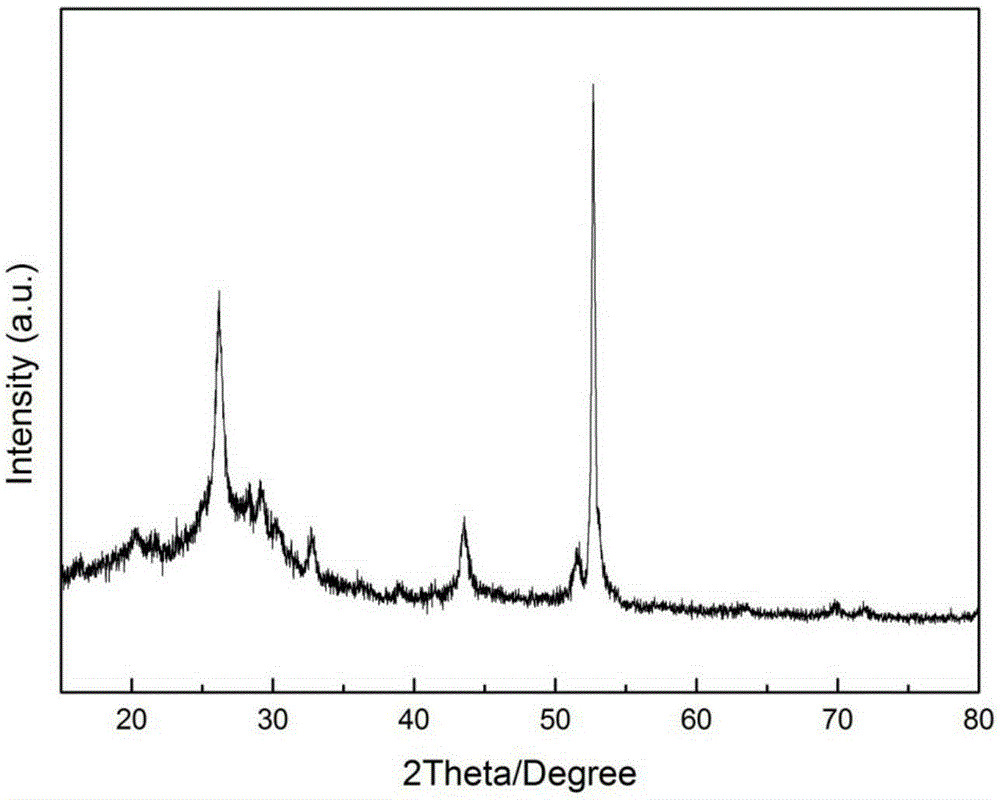

Embodiment 2

[0030] Step 1. Accurately weigh In with a ten-thousandth electronic balance 2 o 3 , P 2 o 5, according to the molar ratio In:P=1.0:1.0~2.0, mix and grind evenly, add anhydrous ethanol equivalent to 50%~100% of the solid raw material mass, grind again carefully, dry to remove the solvent, and use 10~15MPa Press it into a disc with a thickness of 3mm, then seal it in a vacuum ampoule, place it in a quartz boat reactor, and heat it to 500°C to 600°C in a self-made tubular electric furnace with a constant temperature of 2 to 4h, naturally cooled to room temperature, to obtain InPO 4 solid material;

[0031] Step 2. Break the ampoule, and InPO 4 The solid material is placed in the reaction zone of the vertical gradient condensation thin film deposition device, and replaced by high-purity nitrogen to the oxygen concentration at the ppm level, and then Ar+H 2 Mixed gas (containing H 2 The volume percentage is 10% to 30%) vacuum replacement 2 to 3 times, the 6 substrates requir...

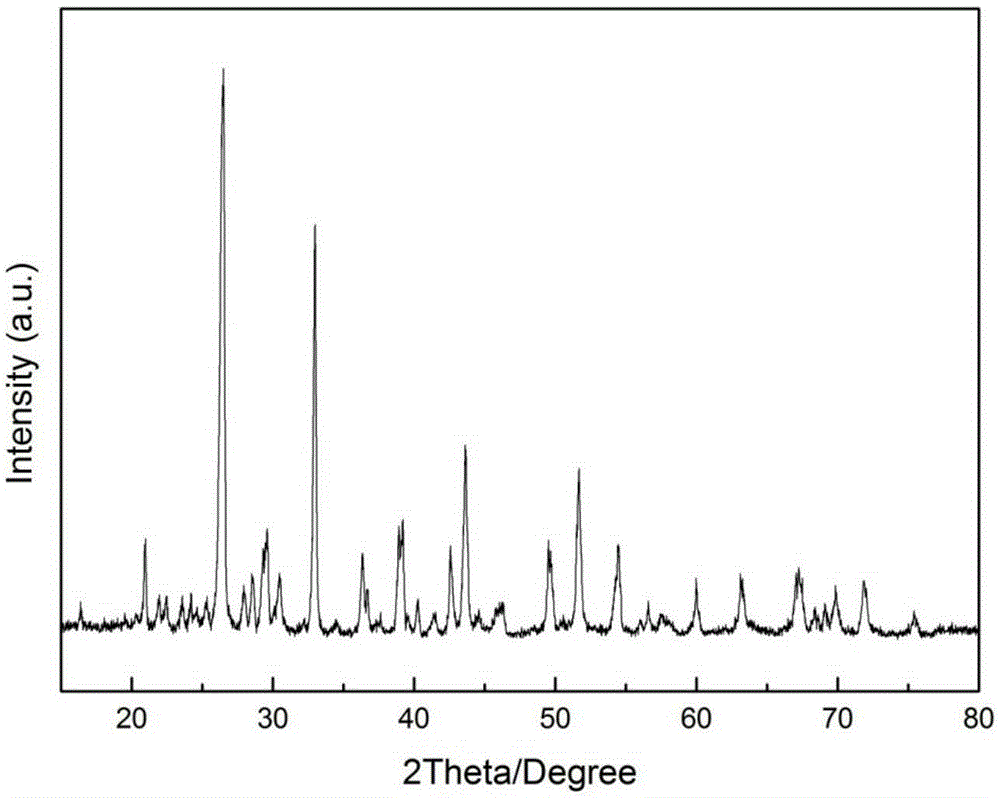

Embodiment 3

[0034] Accurately weigh In with 1 / 10,000 electronic analytical balance 2 o 3 , P 2 o 5 , activated carbon (Active Carbon), according to the ratio of molar ratio In:P:C=1.0:(1.0~1.2):8.0, mix and grind evenly, add anhydrous ethanol equivalent to 50%~100% of the solid raw material quality, and carefully grind evenly , dry to remove the solvent, and press it into a disc or square piece with a thickness of 1-10mm under a pressure of 10-15MPa; then place it in the reaction zone of a vertical gradient condensation thin-film deposition device, and replace it with high-purity nitrogen by vacuuming it into oxygen The concentration is ppm level, and then use Ar+H 2 Mixed gas (containing H 2 The volume percentage is 10% to 30%) vacuum replacement 1 to 2 times, the 6-layer substrate required for deposition is pre-placed in the designated position in the deposition area of the deposition device after treatment; then vacuumize to about 1mmHg, start heating to The reaction zone is 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| hole mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com