A kind of preparation method of large size single crystal perovskite thin film

A perovskite, large-scale technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of small single crystal size, low electrical performance, and poor crystal quality of perovskite thin films. Achieve the effect of increasing size, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

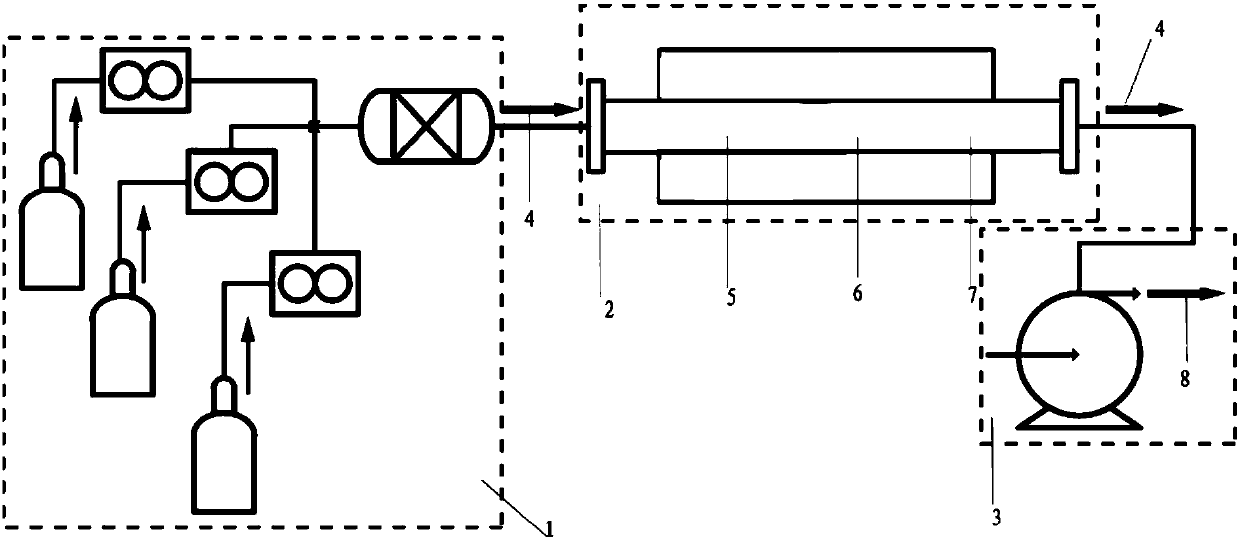

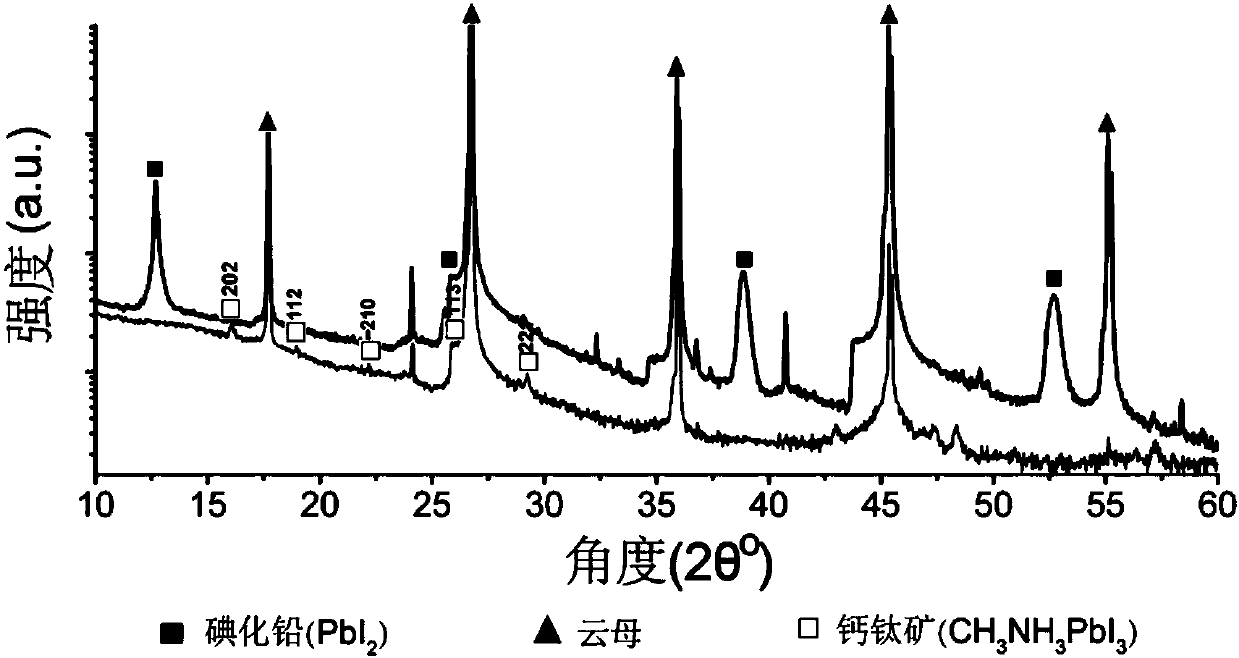

[0033] Specific embodiment one: the preparation method of the large-size single-crystal perovskite film of the present embodiment is carried out according to the following steps:

[0034] 1. Treatment of the growth substrate: the growth substrate is initially treated to obtain the processed growth substrate; the growth substrate includes mica sheet, graphite sheet, graphene, molybdenum disulfide, molybdenum diselenide, molybdenum disulfide Tungsten, tungsten diselenide, tin selenide, stannous selenide or polymer films;

[0035] The processing method of the mica sheet substrate is as follows: use adhesive tape to uncover the surface layer to expose a new surface; , the processing method of tin selenide is: need adopt chemical vapor deposition method to grow out on the silicon dioxide surface; The spin-coating instrument uses a speed of 500-10000 rpm, spin-coats for 5-90 seconds, puts the polymer film obtained by spin-coating on a heating table, and bakes it at 80-200°C for 0.5-3...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment is different from Embodiment 1 in that the polymer film is polymethyl methacrylate film, polydimethylsiloxane film or polyamide film. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

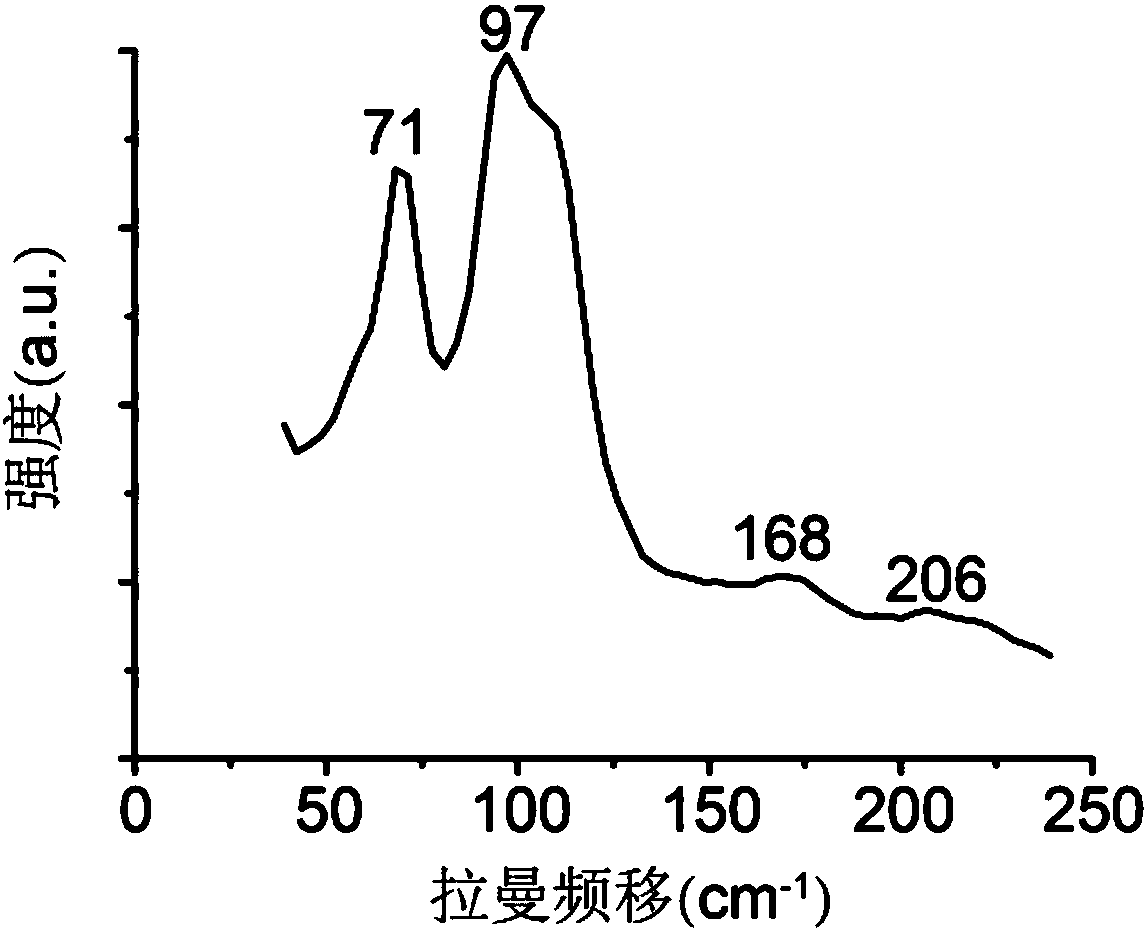

[0038] Embodiment 3: This embodiment is different from Embodiment 1 in that the organic precursor is methyl ammonium chloride, methyl ammonium iodide or methyl ammonium bromide. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com