A kind of tin oxide nanocrystal and its preparation method and solar cell preparation method

A tin oxide nanocrystal, solar cell technology, applied in tin oxide, nanotechnology, nanotechnology and other directions, can solve the problems of increasing the fabrication cost and process difficulty of solar cell devices, limiting applications, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

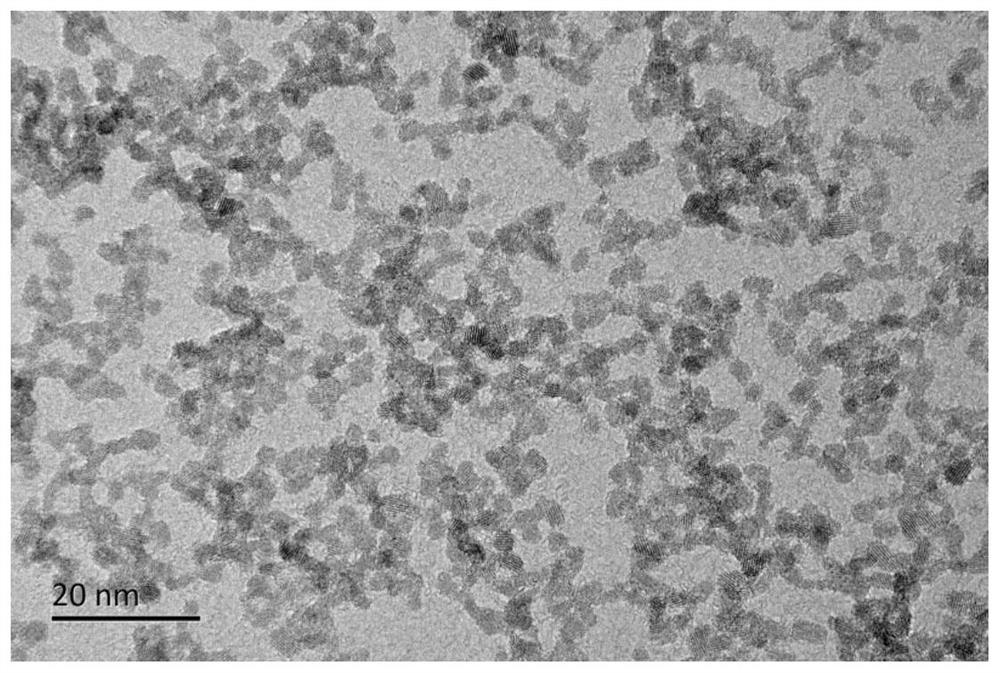

[0040] The invention provides a method for preparing tin oxide nanocrystals, comprising the steps of:

[0041] Take the reaction raw material and add (CH 2 Oh) 2 Made into a solution, the reaction raw materials include: SnCl 4 ·5H 2 O, SnCl 2 2H 2 O, C 4 h 6 o 4 Sn and C 8 h 12 o 8 At least one of Sn, the molar concentration of Sn ions in the solution is 0.1-3mol / L; the reaction raw materials also include doping elements, and the doping elements include any one of Sb, In, and Nb , the molar ratio of the doping element to Sn is 0:4 to 1:4;

[0042] Add glacial acetic acid and ammonia water to adjust the pH value of the solution to 7-10, CH in glacial acetic acid 3 COOH and NH in ammonia 3 ·H 2 The molar ratio of O is 1:1.5 to 1:5;

[0043] React the solution at a temperature of 60-190°C for 10-90 minutes to form a colloidal solution;

[0044] The colloidal solution obtained after the reaction is cleaned according to the following steps:

[0045] a. Add C to the...

Embodiment 1

[0058] This embodiment provides a method for preparing tin oxide nanocrystals, comprising the following steps:

[0059] Take SnCl 4 ·5H 2 OJoin (CH 2 Oh) 2 A solution is made in the solution, and the molar concentration of Sn in the solution is 0.1mol / L;

[0060] Add glacial acetic acid and ammonia water to adjust the pH value of the solution to 7, CH in glacial acetic acid 3 COOH and NH in ammonia 3 ·H 2 The molar ratio of O is 1:1.5;

[0061] Allow the solution to react at a temperature of 60°C for 90 minutes to generate a white colloidal solution;

[0062] The white colloidal solution obtained after the reaction is cleaned according to the following steps:

[0063] a. Add (CH 3 ) 2 CHOH and mix well;

[0064] b. The mixed solution was centrifuged at a speed of 2000r / min for 20 minutes;

[0065] c. Remove the upper layer solution after centrifugation, and keep the lower white precipitate;

[0066] The solution of the white precipitate obtained in step c is circu...

Embodiment 2

[0069] This embodiment provides a method for preparing tin oxide nanocrystals, comprising the following steps:

[0070] Take SnCl 4 ·5H 2 OJoin (CH 2 Oh) 2 A solution is made in the solution, and the molar concentration of Sn in the solution is 0.1mol / L;

[0071] Add glacial acetic acid and ammonia water to adjust the pH value of the solution to 7.5, CH in glacial acetic acid 3 COOH and NH in ammonia 3 ·H 2 The molar ratio of O is 1:2;

[0072] Allow the solution to react at a temperature of 80°C for 80 minutes to generate a white colloidal solution;

[0073] The white colloidal solution obtained after the reaction is cleaned according to the following steps:

[0074] a. Add (CH 3 ) 2 CHOH and mix well;

[0075] b. The mixed solution was centrifuged at a speed of 4000r / min for 16 minutes;

[0076] c. Remove the upper layer solution after centrifugation, and keep the lower white precipitate;

[0077] The solution of the white precipitate obtained in step c is circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com