A kind of preparation method of zno/zns core-shell nanowire array

A nanowire array, nanoarray technology, applied in nanotechnology, nanooptics, nanotechnology, etc., can solve the problems of hidden safety hazards and high temperature, and achieve the effects of reduced risk, high crystallinity, and good shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

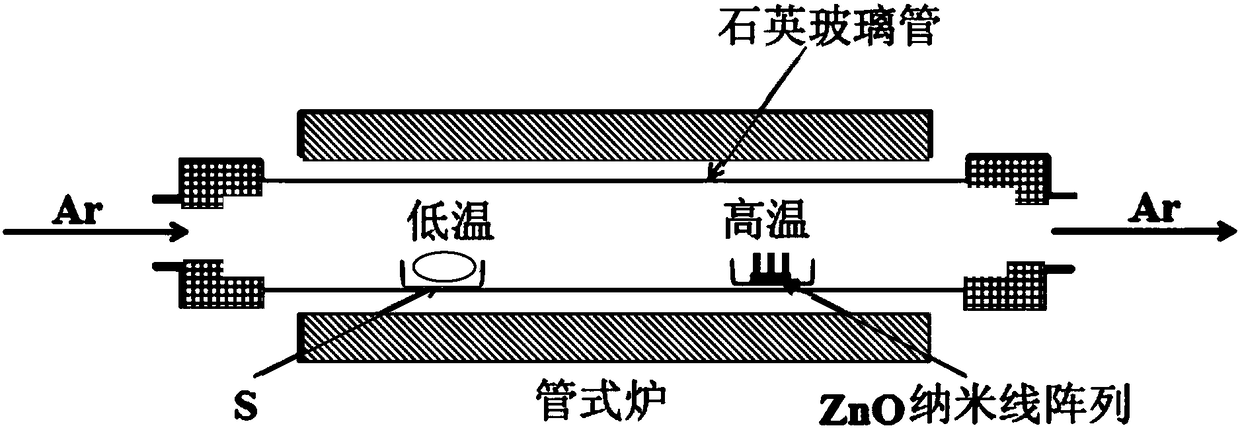

[0020] A method for preparing a ZnO / ZnS core-shell nanowire array, comprising a step of preparing a ZnO nanoarray, using ZnO and graphite powder as raw materials, the two are mixed according to a mass ratio of 1:1, and after fully grinding and mixing, Weigh 0.8 g and put it into a small porcelain boat, the surface of the material is ground, and the Al with a layer of Au catalyst prepared by the electron beam evaporation method is 2 o 3 Put it flat in the center of the material surface in a small porcelain boat, put it into a CVD tube furnace, control the heating time for 30 minutes, when the temperature reaches 910 °C, feed argon, the argon flow rate is 12 sccm, and the holding temperature is 910 °C , the holding time is 5 min, and the temperature is naturally lowered to prepare ZnO nano-arrays;

[0021] It also includes a step of preparing ZnO / ZnS core-shell nano-arrays. The ZnO nano-arrays prepared above are placed in the high-temperature zone of the CVD tube furnace, and a...

Embodiment 2

[0030] This example is basically the same as example 1, the difference is that: in step b, the heat preservation temperature in the high temperature zone is changed to 300°C, 350°C and 500°C, and the intensity of its ZnS characteristic diffraction peak is about the same as that of the heat preservation material at 400°C 0.5 to 3 times.

Embodiment 3

[0032] This example is basically the same as Example 1, except that: in step b, the vulcanization time is changed to 3 min, 10 min and 15 min, and the shell thickness is changed from 15 nm to 200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com