Composite permanent-magnetic material of motor and preparation method of composite permanent-magnetic material

A composite permanent magnet material and raw material technology, applied in the direction of inorganic material magnetism, magnetic circuit characterized by magnetic materials, etc., can solve the problems of rare earth permanent magnet material price rise, user cost increase, benign development impact, etc., and achieve improvement Remanence and Curie temperature, effects of raising Curie temperature and high anisotropy field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

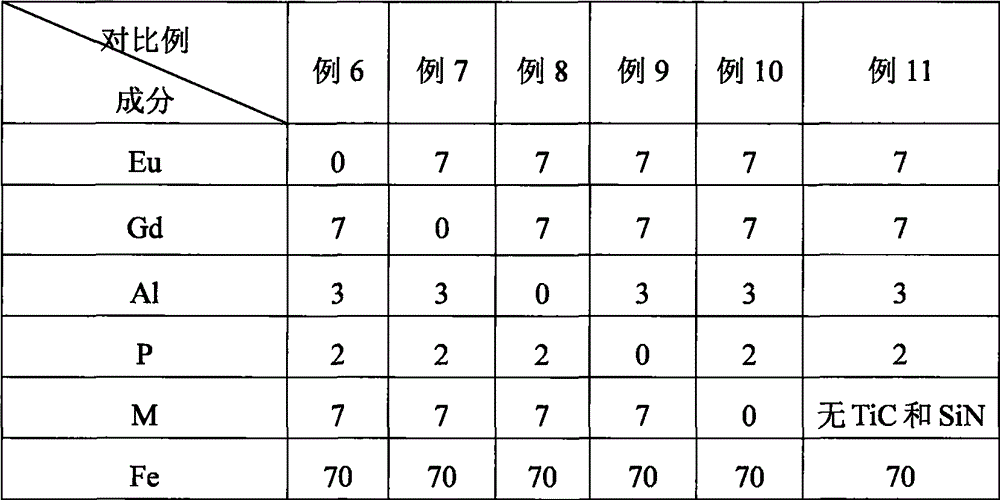

Examples

preparation example Construction

[0021] A method for preparing a composite permanent magnet material for a motor, comprising the steps of:

[0022] (a) Preparation of rare earth permanent magnet ingots: mix Eu, Gd, Fe, Al, P according to the proportioning ratio, mix the weighed raw materials and put them in an intermediate frequency vacuum induction melting furnace for melting to obtain rare earth permanent magnet ingots, wherein, During the smelting process, the heat treatment temperature is 1050°C-1100°C, and the sintering time is 4-6 hours;

[0023] (b) Crushing and pulverizing: the rare earth permanent magnet ingot is first broken into alloy powders with a size of 6 mm by hydrogen cracking, then placed in a reaction vessel to evacuate, and helium gas is introduced to keep the helium pressure at 2 MPa. The jet mill pulverizes the alloy into rare earth magnetic powder with an average particle size of 5-10 μm;

[0024] (c) Preparation of mixed powder: Fe 2 o 3 , Fe 3 o 4 , TiC is mixed according to the ...

Embodiment 1

[0035] A kind of motor composite permanent magnet material, its raw material comprises Eu-Gd-Fe-Al-P-M system, wherein M is made of Fe 2 o 3 , Fe 3 o 4 , TiC and SiN nanoparticles mixed, its particle size range is 20nm, Fe 2 o 3 , Fe 3 o 4 , The mass ratio of TiC and SiN is 10:5:2:1. The mass ratio of Eu, Gd, Fe, Al, P, and M in the system is 5:5:60:2:1:5.

[0036] The preparation method of the motor composite permanent magnet material comprises the steps of:

[0037] 1) Preparation of rare earth permanent magnet ingots: mix Eu, Gd, Fe, Al, and P according to the ratio, mix the weighed raw materials and place them in an intermediate frequency vacuum induction melting furnace for melting to obtain rare earth permanent magnet ingots, wherein the smelting In the process, the heat treatment temperature is 1050°C, and the sintering time is 4 hours;

[0038] 2) Crushing and pulverizing: the rare earth permanent magnet ingot is first crushed into alloy powders with a size of...

Embodiment 2

[0045] A kind of motor composite permanent magnet material, its raw material comprises Eu-Gd-Fe-Al-P-M system, wherein M is made of Fe 2 o 3 , Fe 3 o 4 , TiC and SiN nanoparticles mixed, its particle size range is 25nm, Fe 2 o 3 , Fe 3 o 4 , The mass ratio of TiC and SiN is 10:5:2:1. The mass ratio of Eu, Gd, Fe, Al, P, and M in the system is 6:5:65:3:2:6.

[0046] The preparation method of the motor composite permanent magnet material comprises the following steps:

[0047] 1) Preparation of rare earth permanent magnet ingots: Mix Eu, Gd, Fe, Al, and P according to the proportion, mix the weighed raw materials and put them in an intermediate frequency vacuum induction melting furnace for melting to obtain rare earth permanent magnet ingots. During the melting process , the heat treatment temperature is 1060°C, and the sintering time is 5 hours;

[0048] 2) Crushing and pulverizing: the rare earth permanent magnet ingot is first crushed into alloy powders with a size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com