Method for etching micron silicon through hole

A technology of through-silicon vias and silicon wafers, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as unfavorable expansion of production, inconvenient operation, etc., and achieve good microscopic appearance and fast etching speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

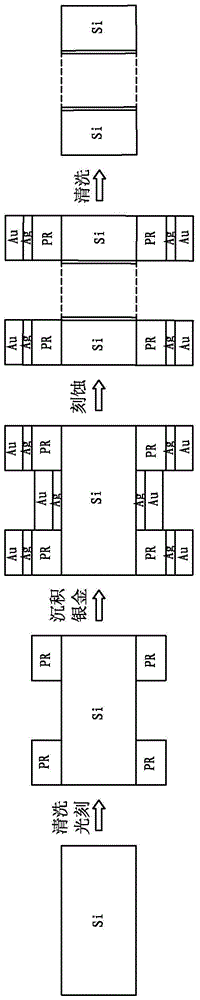

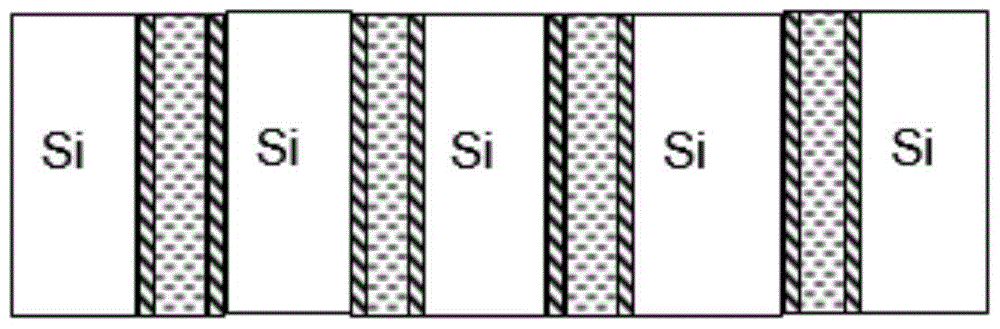

[0033] (1) A silicon wafer with a resistivity of 0.1-1 Ω·cmp and a thickness of 300 μm was ultrasonically cleaned in acetone and ethanol for 5 minutes each, and washed twice. Then wash with hot deionized water and cold deionized water for 2 to 3 times respectively, and blow dry with nitrogen gas for later use.

[0034] (2) Apply photoresist on both sides of the cleaned and dried silicon wafer, bake at 105° C. for 1 minute, expose to photolithography on both sides for 1.4 seconds, and then develop for 45 seconds.

[0035] (3) Using electron beam evaporation equipment, deposit silver with a thickness of 5nm and gold with a thickness of 10nm on the front and back sides of the silicon wafer after photolithography.

[0036] (4) Prepare a 5.74mol / L hydrofluoric acid solution and a 0.46mol / L hydrogen peroxide solution, and mix the two with a volume ratio of 10:1 to prepare a corrosion solution.

[0037] (5) Put the silicon chip in the step (3) into the prepared etching solution for ...

Embodiment 2

[0040] (1) A silicon wafer with a resistivity of 0.1-1 Ω·cmp and a thickness of 300 μm was ultrasonically cleaned in acetone and ethanol for 5 minutes each, and washed twice. Then wash with hot deionized water and cold deionized water for 2 to 3 times respectively, and blow dry with nitrogen gas for later use.

[0041] (2) Apply photoresist on both sides of the cleaned and dried silicon wafer, bake at 105° C. for 1 minute, expose to photolithography on both sides for 1.4 seconds, and then develop for 45 seconds.

[0042] (3) Using electron beam evaporation equipment, deposit silver with a thickness of 5nm and gold with a thickness of 10nm on the front and back sides of the silicon wafer after photolithography.

[0043] (4) Prepare a 5.74mol / L hydrofluoric acid solution and a 0.46mol / L hydrogen peroxide solution, and mix the two with a volume ratio of 10:1 to prepare a corrosion solution.

[0044] (5) Put the silicon chip in the step (3) into the prepared etching solution for ...

Embodiment 3

[0047] (1) A silicon wafer with a resistivity of 0.01-0.09 Ω·cmp and a thickness of 300 μm was ultrasonically cleaned in acetone and ethanol for 5 minutes each, and cleaned twice. Then wash with hot deionized water and cold deionized water for 2 to 3 times respectively, and blow dry with nitrogen gas for later use.

[0048] (2) Apply photoresist on both sides of the cleaned and dried silicon wafer, bake at 105° C. for 1 minute, expose to photolithography on both sides for 1.4 seconds, and then develop for 45 seconds.

[0049] (3) Using electron beam evaporation equipment, deposit silver with a thickness of 5nm and gold with a thickness of 10nm on the front and back sides of the silicon wafer after photolithography.

[0050] (4) Prepare a 5.74mol / L hydrofluoric acid solution and a 0.46mol / L hydrogen peroxide solution, and mix the two with a volume ratio of 10:1 to prepare a corrosion solution.

[0051] (5) Put the silicon chip in the step (3) into the prepared etching solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com