Long-service-life concrete for steel-concrete composite beam hogging moment area and preparation method long-service-life concrete

A technology of negative moment zone and composite beam, which is applied in the field of long-life concrete preparation, can solve the problems of reducing concrete durability, concrete deterioration, structural damage, etc., and achieve stress concentration relief, bond strength improvement, high toughness and crack resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

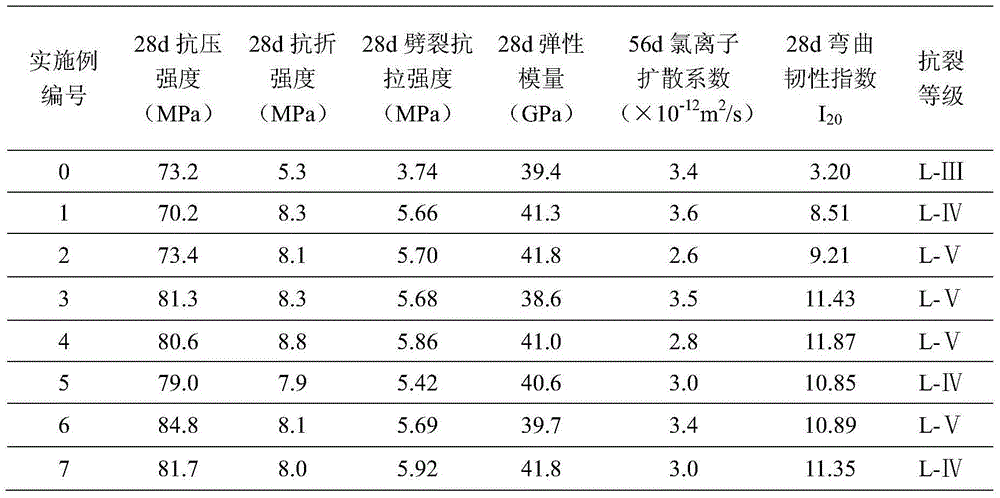

Examples

preparation example Construction

[0035]The preparation method of the long-life concrete used in the negative moment zone of the above-mentioned steel-concrete composite beam in the embodiment of the present invention comprises the following steps:

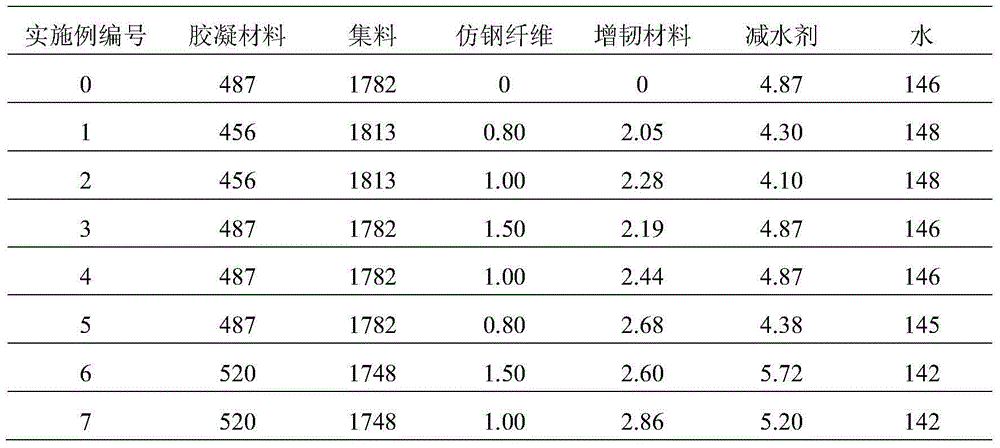

[0036] S1: Add 456-520 parts of cementitious material and 1748-1813 parts of aggregate into the mixer in parts by mass, uniformly stir the cementitious material and aggregate for 30 seconds, and go to step S2.

[0037] S2: Sprinkle 0.80-1.50 parts of imitation steel fiber into the mixer, mix the cementitious material, aggregate and imitation steel fiber together for 30 seconds, and turn to step S3.

[0038] S3: Combine 4.10-5.72 parts of water reducer with 142-148 parts of water to form a mixed solution; add the mixed solution and 2.05-2.86 parts of toughening material to the mixer in turn, and mix the cementitious material, aggregate, imitation steel fiber, and The liquid and the toughening material were stirred together for 3 minutes to obtain a pumpable concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com