A high-temperature cementing cement system for hot dry rock water injection wells

A technology for cementing cement and water injection wells, which is applied in the field of cement slurry system, can solve the problems such as failure to achieve high temperature strength stability, high toughness and high thermal conductivity, achieve high compressive strength stability, improve recession, and improve high temperature The effect of strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-temperature cementing cement system for hot dry rock water injection wells, belonging to the technical field of cement slurry systems, adopts low-calcium-silicon-ratio cement as the base cement, C 2 The S content is 50.2%, and the specific surface area is 283m 2 / kg, 7d heat of hydration ≤ 182kJ / kg; the waste concrete is crushed and ground, and the fineness of the powder is controlled to 300 mesh, and the SiO in the powder 2 The tin content is 73.4%; the carbon fiber diameter is 6µm, and the tensile strength is 3000MPa; the tin content in metal tin powder is 99.95%, and the fineness is 325 mesh.

[0037] The specific composition is as follows:

[0038]

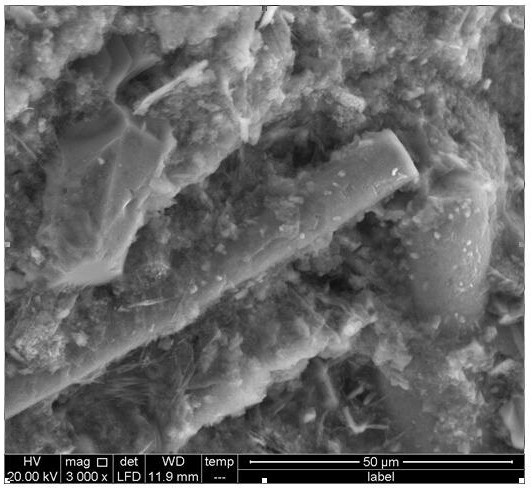

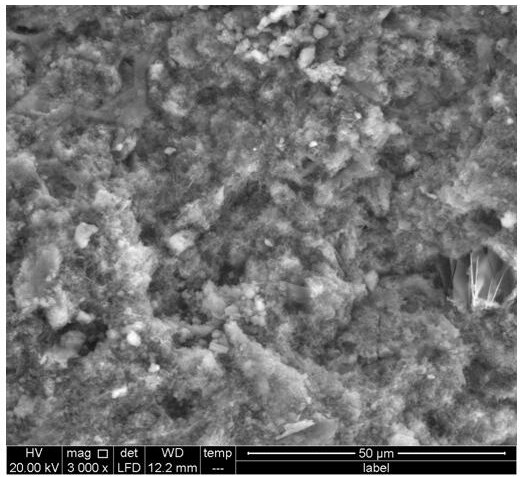

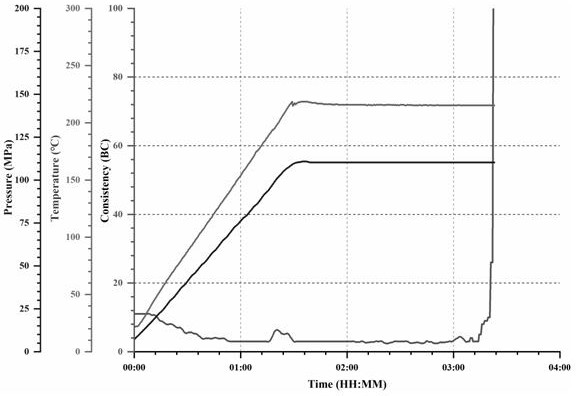

[0039] Take raw materials according to the specific composition ratio in the above table, mix them, and prepare cement slurry according to GB / T 19139, with a water-cement ratio of 0.45, to obtain well cementing cement slurry. Samples were taken and cured at 240°C. The results are shown in Figure 1.

Embodiment 2

[0041] Select the materials in Example 1, add materials according to the ratio in the table below, and ensure the water-cement ratio is 0.45 to obtain well cementing cement slurry.

[0042]

Embodiment 3

[0044] In this embodiment, low hydration heat cement is adopted as base cement, C 2 The S content is 44.5%, and the specific surface area is 325m 2 / Kg, 7d hydration heat ≤ 216kJ / kg, water-cement ratio 0.45, the specific composition is as follows:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com