A high-voltage monocrystalline ternary material and a preparation method thereof

A ternary material, high-voltage technology, applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problems of poor contact between materials and binders, conductive agents, poor electrode filling performance, and low tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

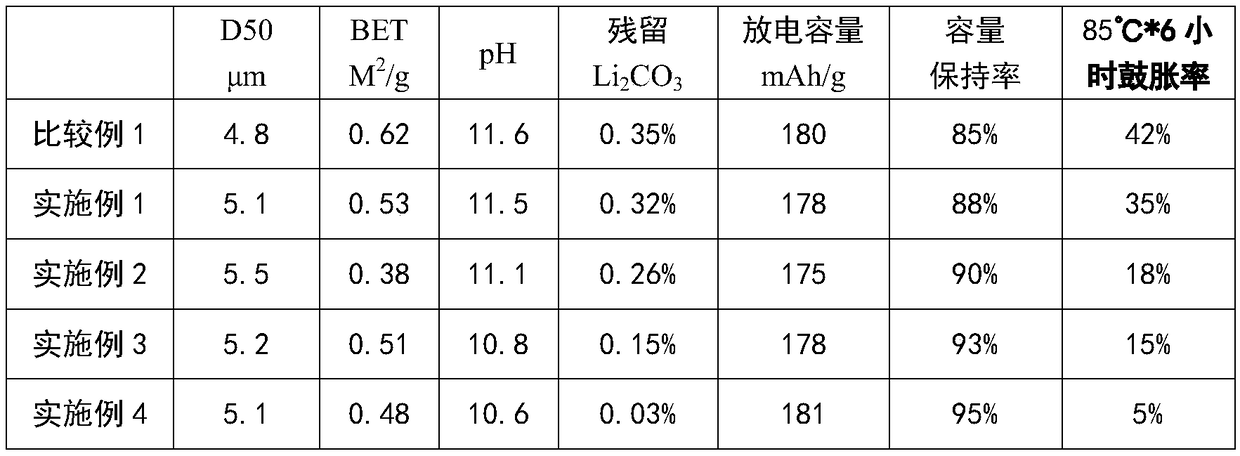

Examples

preparation example Construction

[0024] A method for preparing a high-voltage single crystal nickel-cobalt-manganese ternary material powder, characterized in that it comprises the following steps:

[0025] 1) Co-precipitation method to prepare doped nickel-cobalt-manganese hydroxide precursor

[0026] Co-precipitation is used to make the distribution of the three elements of nickel, cobalt and manganese and doping elements more uniform, which can improve the electrochemical performance of the ternary material; the present invention uses the co-precipitation method to prepare the doped nickel-cobalt-manganese hydroxide precursor, by controlling the process Conditions, so that the center particle size of the oxide co-precipitation body is 3.0-5.0 μm, and reduce super large particles as much as possible. The specific process is as follows:

[0027] According to the chemical formula Ni 0.5 co 0.2 mn 0.3 (OH) 3 Carry out batching, first take required nickel sulfate, cobalt sulfate, manganese sulfate accordin...

Embodiment 1

[0048] Weigh 77.38g of nickel sulfate, 31.00g of cobalt sulfate, 45.30g of manganous sulfate, and dissolve 1.50g of yttrium sulfate in 1L of pure water to form a 1.0mol / L nickel-cobalt-manganese sulfate solution, pour it into an airtight container protected by an inert gas, and heat To 80°C, under rapid stirring conditions, slowly add dilute ammonia water to make the system pH = 3.0-3.5, continue to slowly add NaOH-ammonia water mixed solution to keep the system pH at 11.0-11.5. After the system reaction is completed, it is aged for 5 hours. The obtained precipitate was fully washed with hot deionized water to pH = 7-8, and the precipitate was separated by filtration until the water content reached 50%, and 26.33 g of lithium hydroxide was added to form a paste mixture. After fully stirring, it was vacuum-dried Dry the paste in the same way, then pulverize it, and pass through a 160-mesh sieve. Put the mixture of lithium salt and hydroxide obtained by the above sieving into a...

Embodiment 2

[0050] Weigh 77.38g of nickel sulfate, 31.00g of cobalt sulfate, 45.30g of manganese sulfate, and dissolve 1.05g of tungsten sulfate in 1L of pure water to form a 1.0mol / L nickel-cobalt-manganese sulfate solution, pour it into an airtight container protected by an inert gas, and heat To 85°C, under rapid stirring conditions, slowly add dilute ammonia water to make the system pH = 3.0-3.5, continue to slowly add NaOH-ammonia water mixed solution to maintain the system pH at 11.0-11.5. After the system reaction is completed, it is aged for 5 hours. The obtained precipitate was fully washed with hot deionized water until pH = 7-8, and the precipitate was separated by filtration until the water content reached 50%, and 27.53 g of lithium hydroxide was added to form a paste mixture. After fully stirring, it was vacuum-dried Dry the paste in the same way, then pulverize it, and pass through a 160-mesh sieve. Put the mixture of lithium salt and hydroxide obtained by the above sievin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central granularity | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com