Method for preparing spherical molybdenum powder

A powder and spherical technology, which is applied in the field of preparing spherical molybdenum powder, can solve the problems of complicated process, complicated additives, and secondary pollution of molybdenum powder, and achieve the goals of improving microscopic appearance, low cost, and increasing bulk density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Using ball milling, 3000g of conventional reduced molybdenum powder is ball milled for 240min under the condition that the ball-to-material ratio is 1:1;

[0037] Step 2, dissolving 61.2g of polyvinyl alcohol into 1230mL of deionized water to prepare an aqueous solution of polyvinyl alcohol;

[0038] Step 3, adding the molybdenum powder pulverized in step 1 into the polyvinyl alcohol aqueous solution described in step 2, and stirring evenly to make a slurry;

[0039] Step 4: Spray-dry the slurry described in Step 3 to obtain granulated powder; the air inlet temperature of the spray-dried drying tower is 220°C, the air outlet temperature is 120°C, and the rotational speed of the centrifugal atomizing disc is 10500rpm;

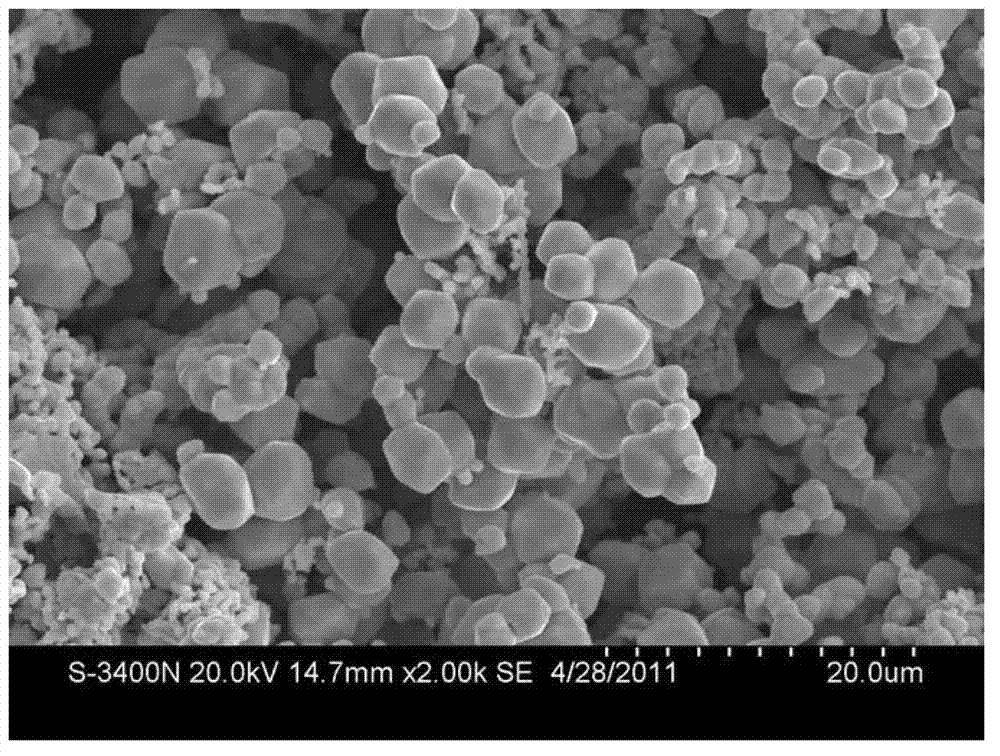

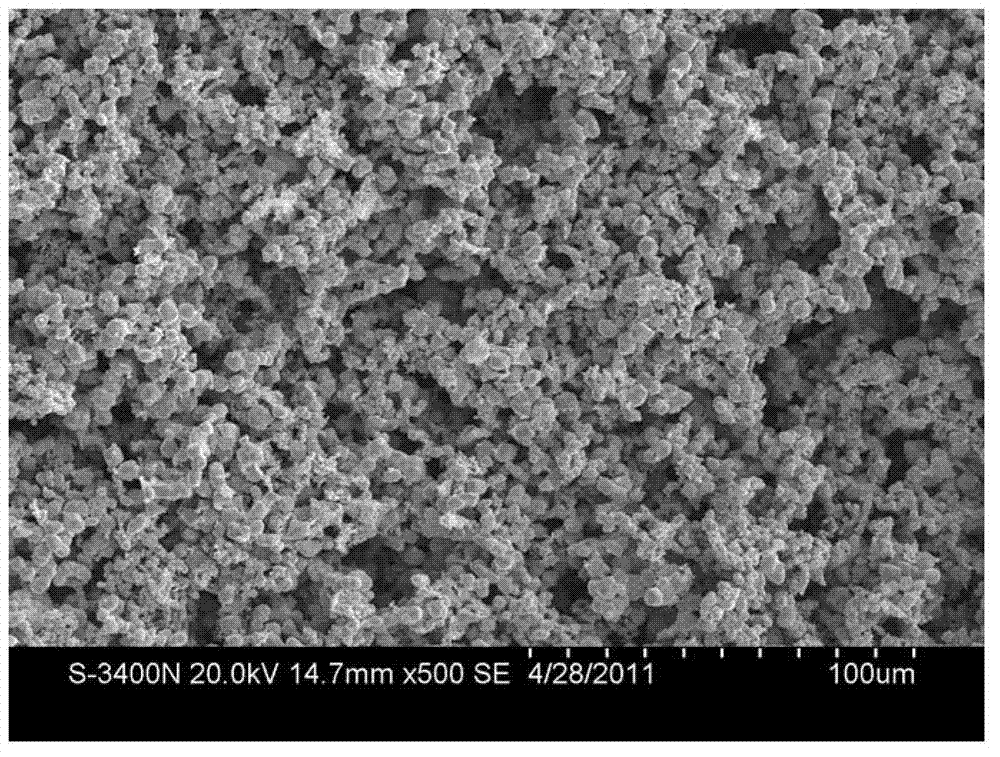

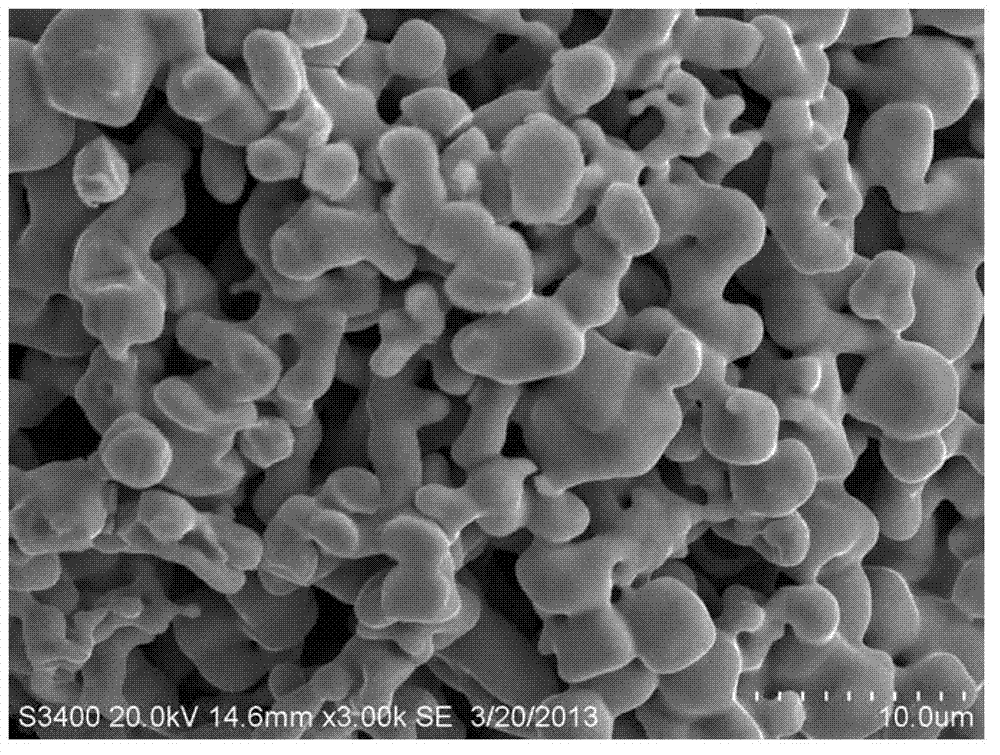

[0040] Step 5. Degrease the granulated powder described in step 4 at 900°C for 2 hours under a wet hydrogen atmosphere with a dew point of 35°C, then heat-treat at 1200°C for 8 hours under a hydrogen atmosphere, and finally crush it through a -100...

Embodiment 2

[0043] Step 1. Using jet milling method, 3000g conventional reduced molybdenum powder is subjected to high-energy fluidized bed collision jet milling, the rotating speed is 10000r / min, and the processing time is 80min;

[0044]Step 2, dissolving 70g of polyvinyl alcohol into 1400mL of deionized water to prepare an aqueous solution of polyvinyl alcohol;

[0045] Step 3, adding the molybdenum powder pulverized in step 1 into the polyvinyl alcohol aqueous solution described in step 2, and stirring evenly to make a slurry;

[0046] Step 4: Spray-dry the slurry described in Step 3 to obtain granulated powder; the air inlet temperature of the spray-dried drying tower is 230°C, the air outlet temperature is 150°C, and the rotational speed of the centrifugal atomizing disc is 11500rpm;

[0047] Step 5. Degrease the granulated powder described in step 4 at 800°C for 4 hours under a wet hydrogen atmosphere with a dew point of 40°C, then heat-treat at 1300°C for 6 hours under a hydrogen ...

Embodiment 3

[0050] Step 1. Using ball milling, 3000g of conventional reduced molybdenum powder is ball milled for 20min under the condition that the ball-to-material ratio is 4:1;

[0051] Step 2, dissolving 58g of polyvinyl alcohol into 1200mL of deionized water to prepare an aqueous solution of polyvinyl alcohol;

[0052] Step 3, adding the molybdenum powder pulverized in step 1 into the polyvinyl alcohol aqueous solution described in step 2, and stirring evenly to make a slurry;

[0053] Step 4: Spray-dry the slurry described in Step 3 to obtain granulated powder; the air inlet temperature of the spray-dried drying tower is 250°C, the air outlet temperature is 115°C, and the rotational speed of the centrifugal atomizing disc is 11000rpm;

[0054] Step 5. Degrease the granulated powder described in step 4 at 700°C for 8 hours under a wet hydrogen atmosphere with a dew point of 55°C, then heat-treat at 1400°C for 4 hours under a hydrogen atmosphere, and finally crush it through a -100 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com