Microwave sintering method for PTC ceramics

A microwave sintering and ceramics technology, which is applied in the field of electronic ceramics manufacturing technology, can solve the problems of immature microwave sintering PTC technology, deformation of PTC ceramic sheets, and no large-scale application, and achieve good compactness, lower sintering temperature, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

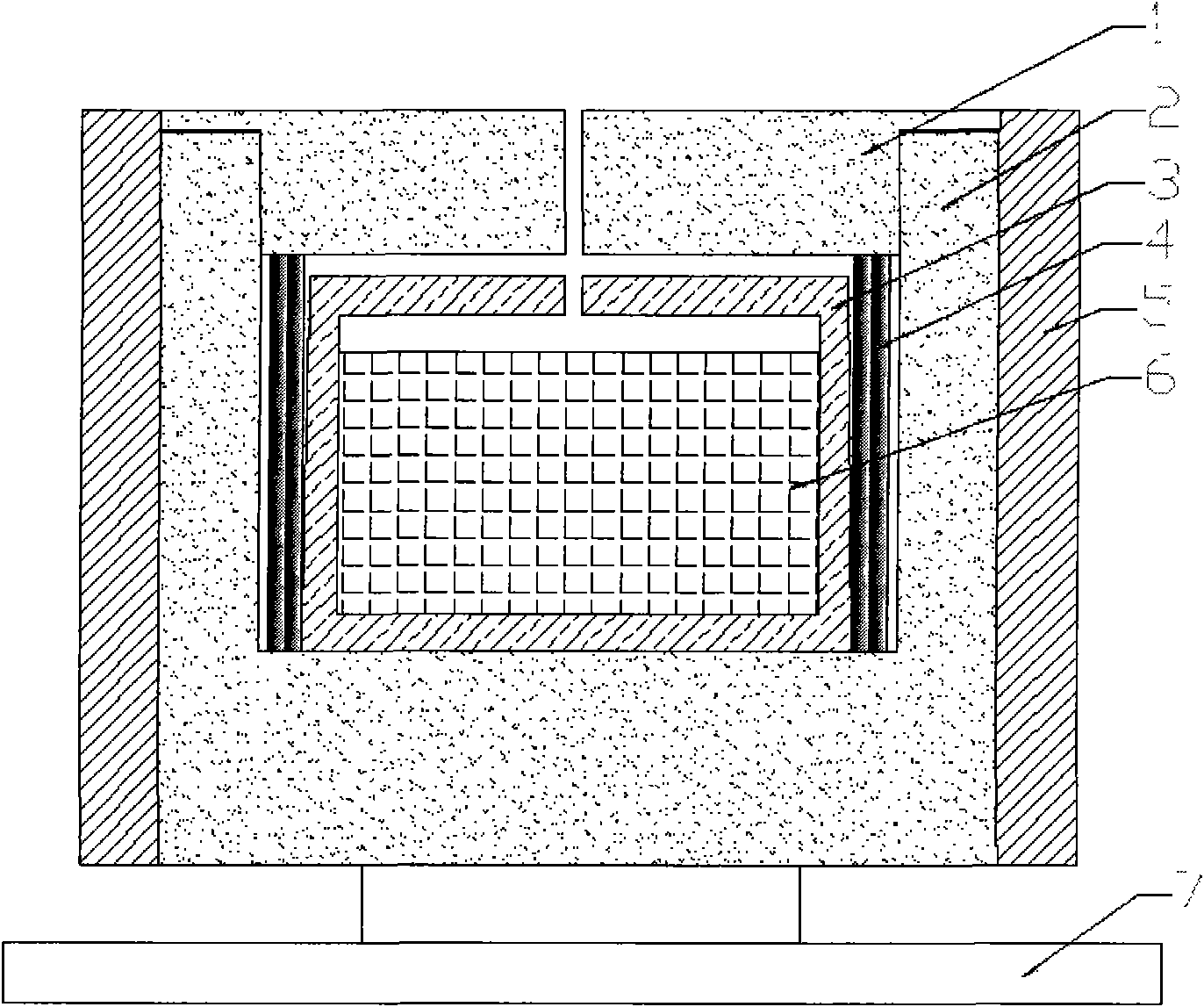

[0013] a. Put the PTC green body 6 into the crucible 3, then put the crucible into the furnace 2, cover the cover plate 1, and then put them into the microwave reaction chamber for sintering. The hole in the middle of the cover plate 1 is a temperature measurement hole for infrared temperature measurement. The outside of the thermal insulation body 2 is an alumina fiber layer 5, which is wound by a thin asbestos rope. Between the furnace 2 and the crucible 3 is a SiC rod 4, which is used as an auxiliary heating material.

[0014] b. The sintering process is: heating from room temperature to 500°C, at a rate of 500°C / hour, and then debinding at a constant temperature for 1 hour to eliminate the organic binder in the PTC green body, from 500 to 1250°C to 600°C The temperature is increased at a rate of 1 / hour, and then kept for 10 minutes for sintering. Afterwards, it is kept at 1100°C for 20 minutes to complete the entire sintering process.

[0015] c. During the sintering process, ...

Embodiment 2

[0018] a. The existing PTC green body 6 is heated to 500°C in a common heating furnace, and the temperature is maintained for 60 minutes to remove the organic binder in the PTC green body. After that, the PTC green body 6 is put into the crucible 3, and then the crucible is put into the furnace 2, covered with the cover plate 1, and then put into the microwave reaction chamber for sintering. The hole in the middle of the cover plate 1 is a temperature measurement hole for infrared temperature measurement. The outside of the furnace 2 is alumina fiber 5, and a SiC rod is evenly placed between the furnace 2 and the crucible 3.

[0019] b. The sintering process is: from room temperature to -1220°C, heating at a rate of 500°C / hour, and then holding for 30 minutes. Afterwards, it is kept at 1100°C for 10 minutes to complete the entire sintering process.

[0020] c. The remaining steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com