Novel method for preparing ferrite ceramic soft magnetic material

A soft magnetic material and ferrite technology, which is applied in the field of electronic ceramics preparation and application, can solve the problems of complicated preparation process and operation, achieve few process steps, uniform and controllable grain size, saturation magnetization and Curie high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

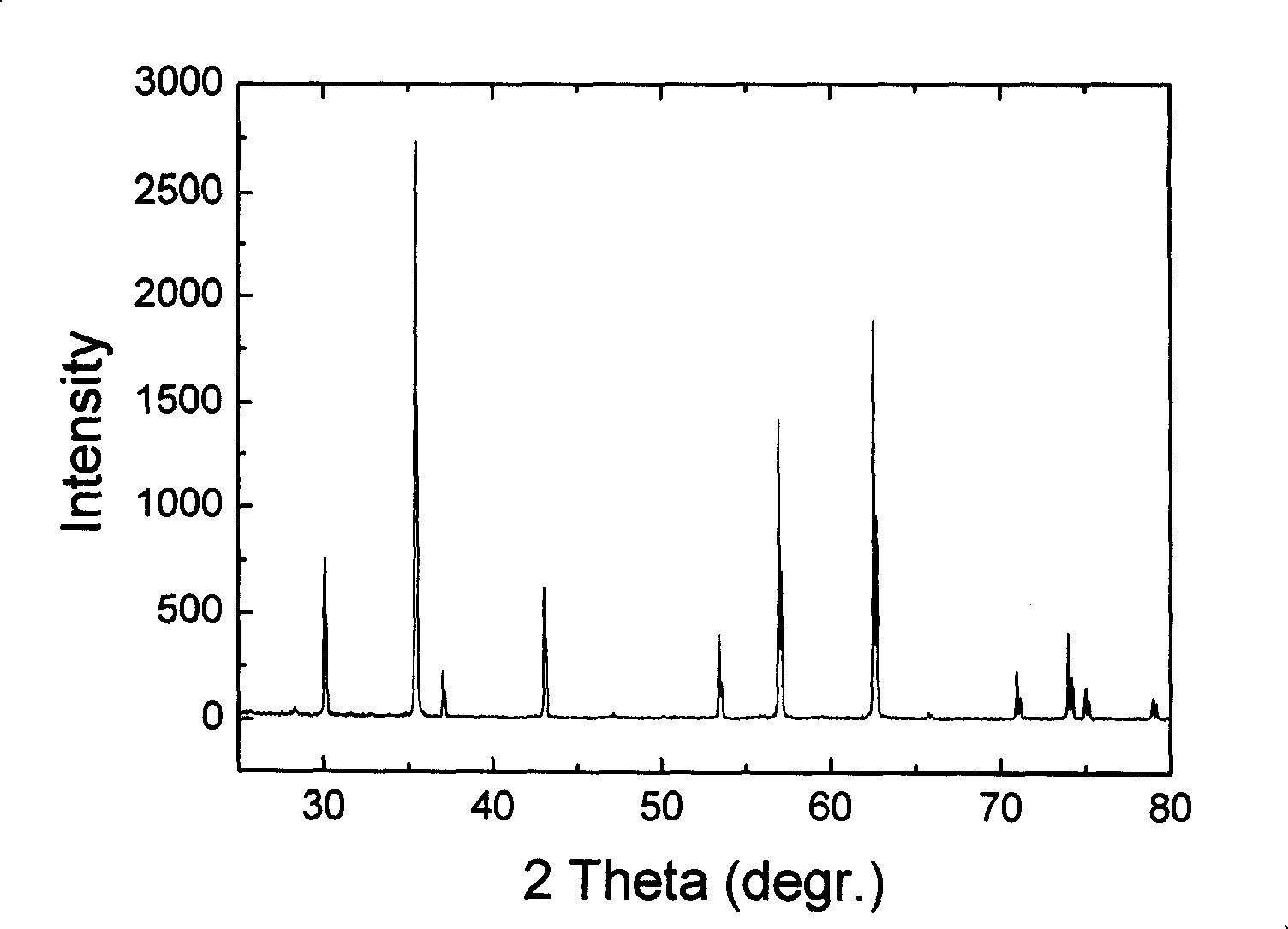

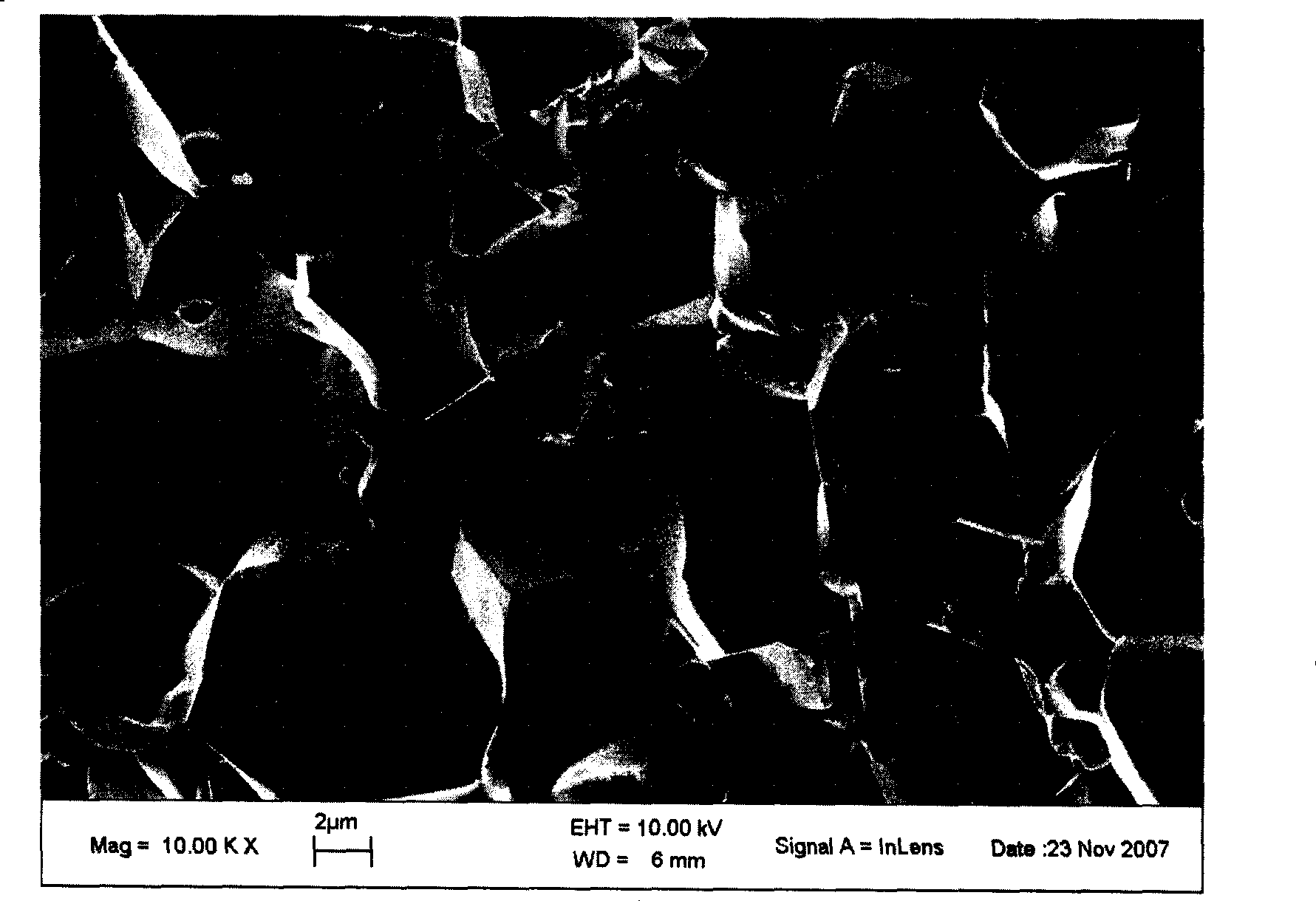

[0035] Embodiment 1: commercially available analysis pure NiO, ZnO, Fe 2 o 3 According to 0.5:0.5:1 molar ratio mixing, and add 1% (mass fraction) Bi 2 o 3 , 2% (mass fraction) MnCO 3 , 0.3% (mass fraction) polyvinyl alcohol and 0.05% (mass fraction) DavonC, press 1:2:1 powder: zirconium ball: deionized water mass ratio is put into polyurethane ball mill tank, ball mills on high-energy ball mill for 48 hours Finally, it is dried in the air at 130°C for 48 hours in a drying oven, mixed and sized and sieved, then dry-pressed and sintered at 1150°C for 2 hours. The resulting material is a phase-pure spinel ferrite (see figure 1 ), the grain size is uniform (see figure 2 ), the saturation magnetic moment per unit mass is 75.16emu / g, the coercive force is 2.34Oe, and the Curie temperature is 325°C; the cut-off frequency is in the high frequency range, the high frequency performance is good, and the magnetic permeability at 1MHz is 322.09; within the frequency range of 1k-100M...

Embodiment 2

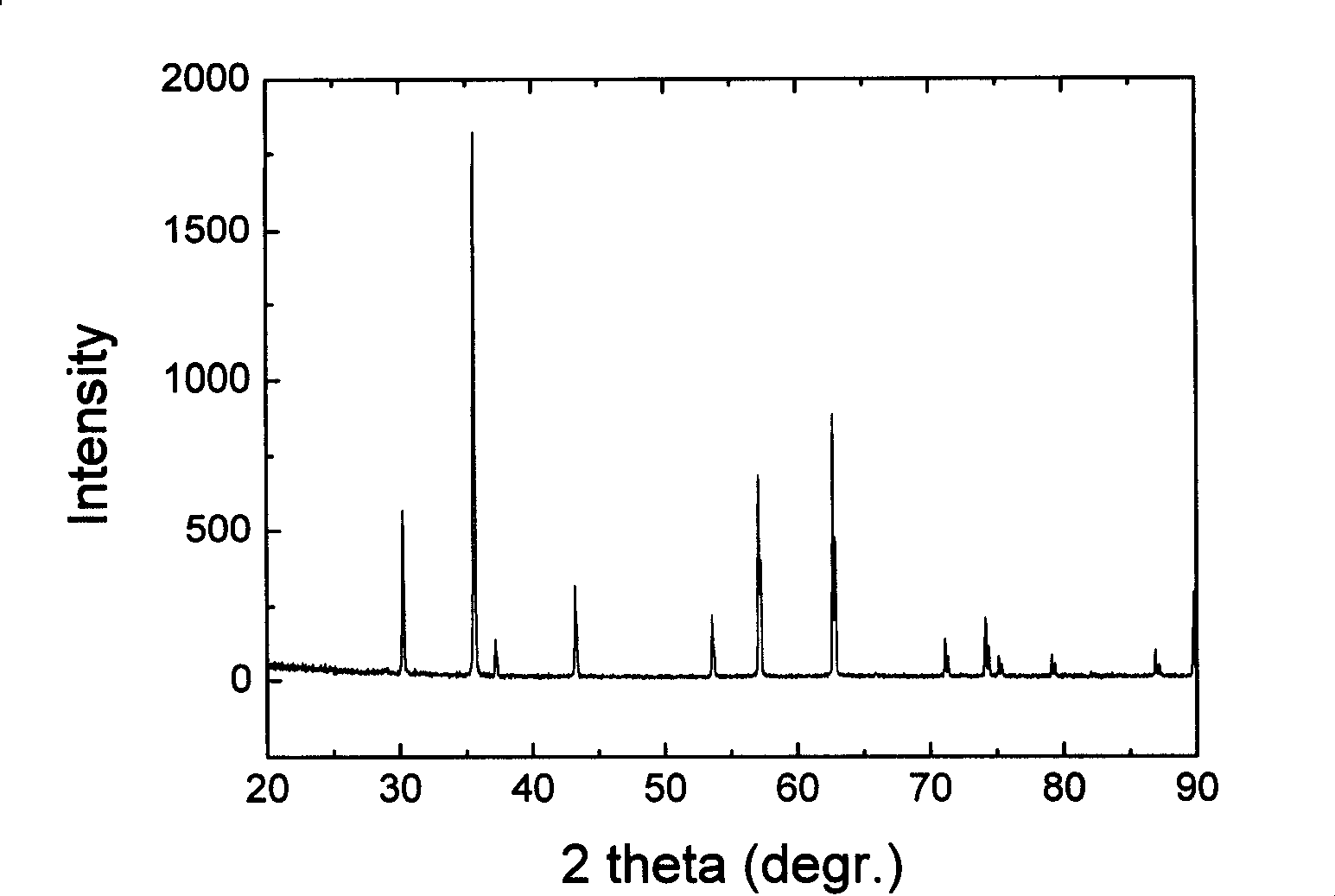

[0036] Embodiment 2: commercially available analysis pure NiO, ZnO, Fe 2 o 3 、Al 2 o 3 Mix by 0.5:0.5:0.965:0.035 molar ratio, and add 1% (mass fraction) Bi 2 o 3 , 2% (mass fraction) MnCO 3 , 0.3% (mass fraction) polyvinyl alcohol and 0.05% (mass fraction) Davon C, press 1:2:1 powder material: zirconium ball: deionized water mass ratio is put into polyurethane ball mill jar, ball mills 48 on the high-energy ball mill After 1 hour, it was dried in the air at 130°C for 48 hours in a drying oven, mixed and granulated and sieved, then dry-pressed and sintered at 1170°C for 2 hours. The resulting material is a phase-pure spinel ferrite (see image 3 ), the grain size is uniform (see Figure 4); the saturation magnetic moment per unit mass is 71.13emu / g, the coercive force is 2.7366 Oe, and the Curie temperature is 325°C; the cut-off frequency is in the high frequency range, the high frequency performance is good, and the magnetic permeability is 255.02 at 1MHz; in the frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com