Microwave dielectric ceramic material, preparation method and application thereof, microwave dielectric ceramic body, preparation method and application of microwave dielectric ceramic body, and microwave device

A technology of microwave dielectric ceramics and microwave devices, applied in the field of electronic ceramics, can solve problems such as poor temperature stability and low dielectric constant, and achieve the effect of high temperature stability and good temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

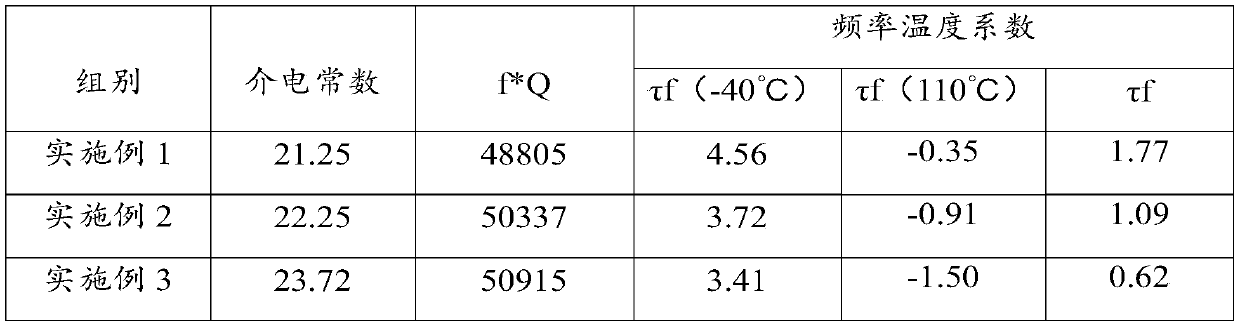

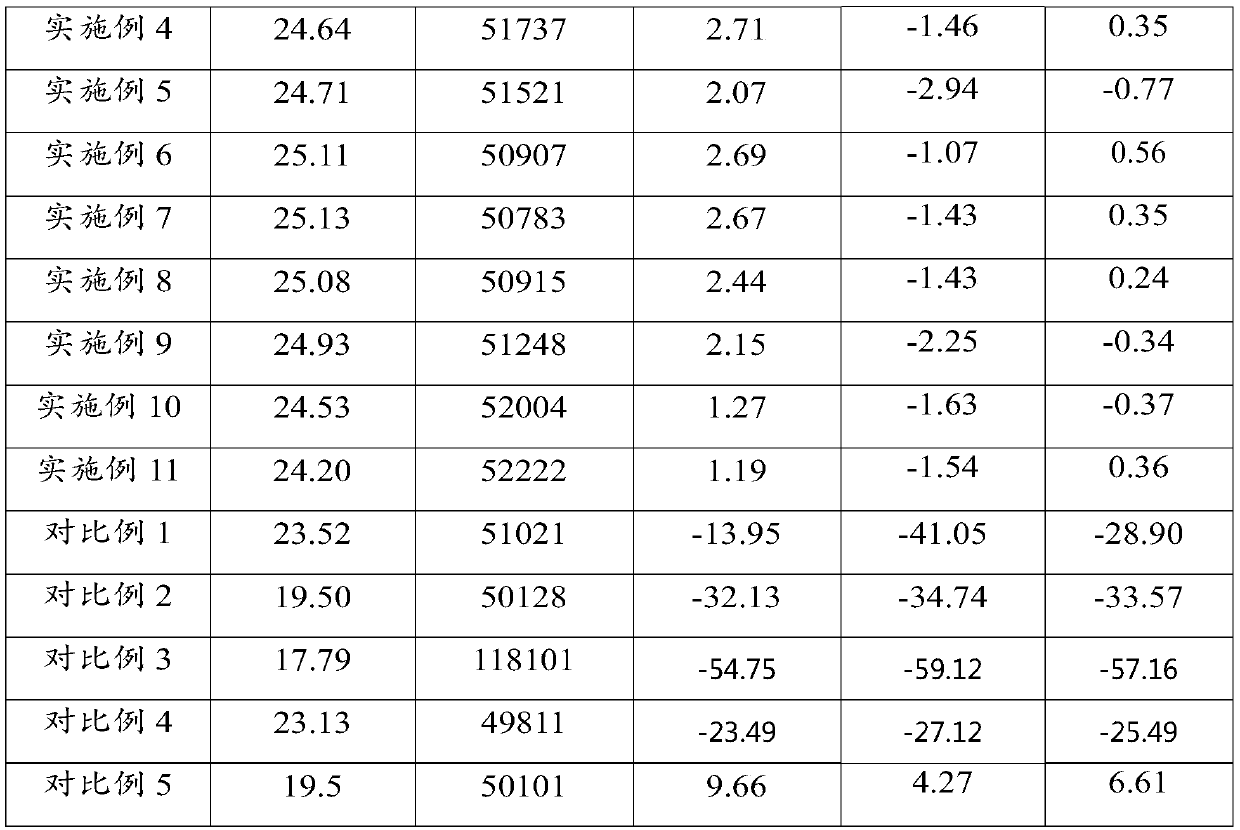

Examples

preparation example Construction

[0062]According to another aspect of the present invention, a method for preparing the above-mentioned microwave dielectric ceramic material is provided, comprising: mixing and dispersing each component and then calcining to obtain the microwave dielectric ceramic material. The method has scientific and simple process, is suitable for industrial mass production, and the obtained microwave dielectric ceramic material has lower dielectric constant, proper f*Q and higher temperature stability.

[0063] In a preferred embodiment, MgO, CaO, SiO 2 、Nd 2 o 3 、TiO 2 , optional Sm 2 o 3 Mix and disperse with an optional oxide of R, and then calcine;

[0064] Or, (a) combine MgO and TiO 2 Synthesis of MgTiO by Calcination after Mixing and Dispersion 3 and / or Mg 2 TiO 4 , (b) MgO and SiO 2 Calcination to synthesize Mg after mixing and dispersing 2 SiO 4 and optionally MgSiO 3 , (c) CaO and TiO 2 Synthesis of CaTiO by Calcination after Mixing and Dispersion 3 , (d) CaO, Nd ...

Embodiment 1

[0085] A microwave dielectric ceramic material prepared from ceramic main materials:

[0086] According to the weight percentage of each component in the microwave dielectric ceramic material, the main ceramic materials include: MgO 30%, CaO 5.5%, SiO 2 10%, Nd 2 o 3 7.5% and TiO 2 47%;

[0087] The particle size of each component is 550nm.

Embodiment 2

[0089] A microwave dielectric ceramic material, which is mainly prepared from ceramic main materials:

[0090] According to the weight percentage of each component in the microwave dielectric ceramic material, the main ceramic materials include: MgO 33%, CaO 4.5%, SiO 2 10%, Nd 2 o 3 5.5% and TiO 2 47%;

[0091] The particle size of each component is 550nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com