Cordierite microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and ceramic materials, which is applied in the field of electronic ceramic materials, can solve the problems of small increase in the temperature coefficient of resonance frequency, unstable influence of material temperature, and small increase in quality factor, etc., to improve signal transmission speed and high quality. factor, the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

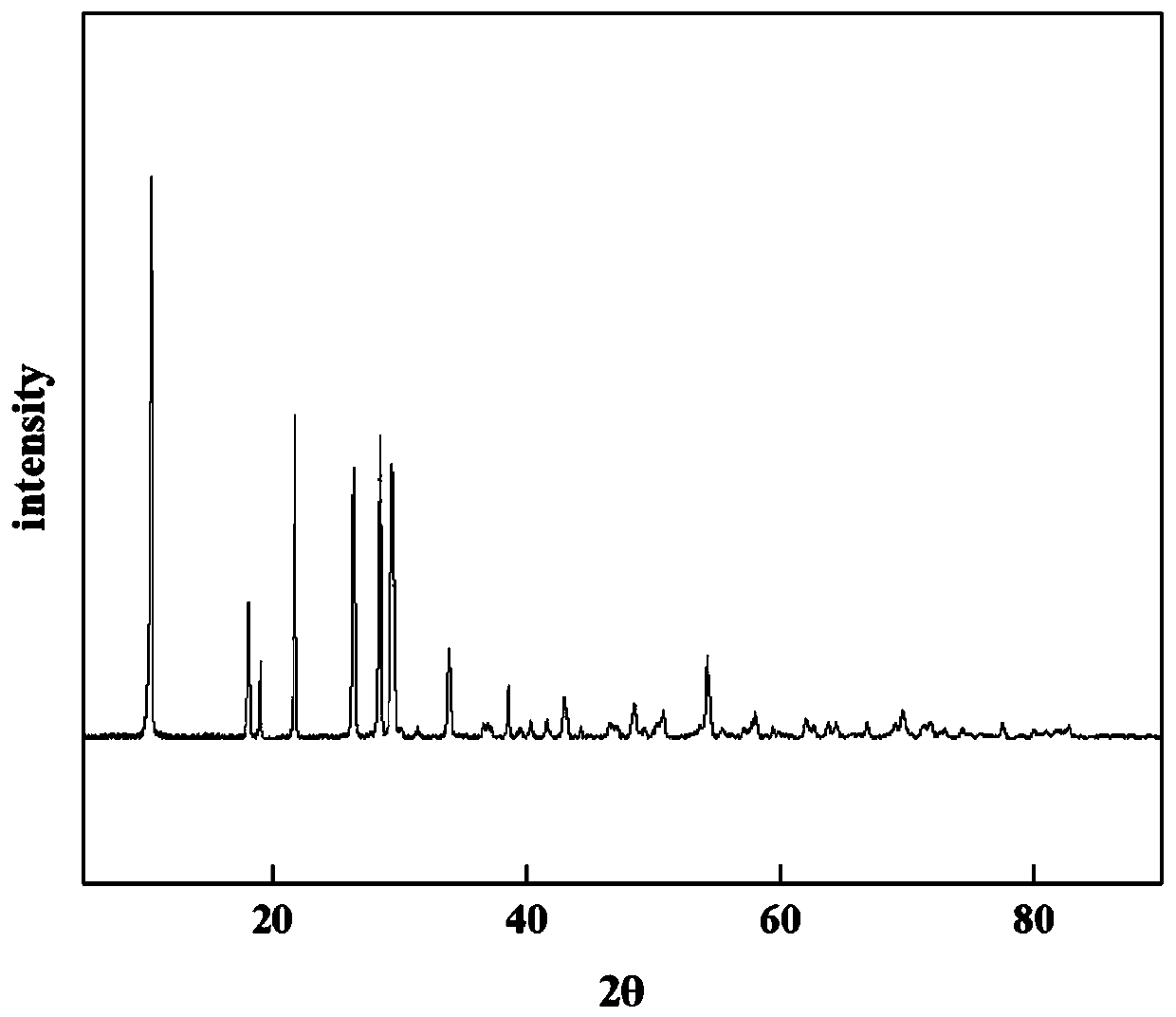

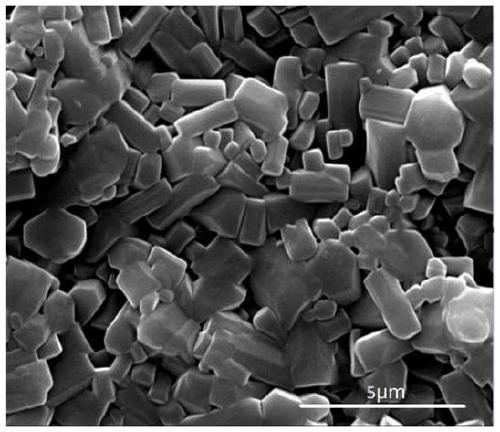

Image

Examples

Embodiment

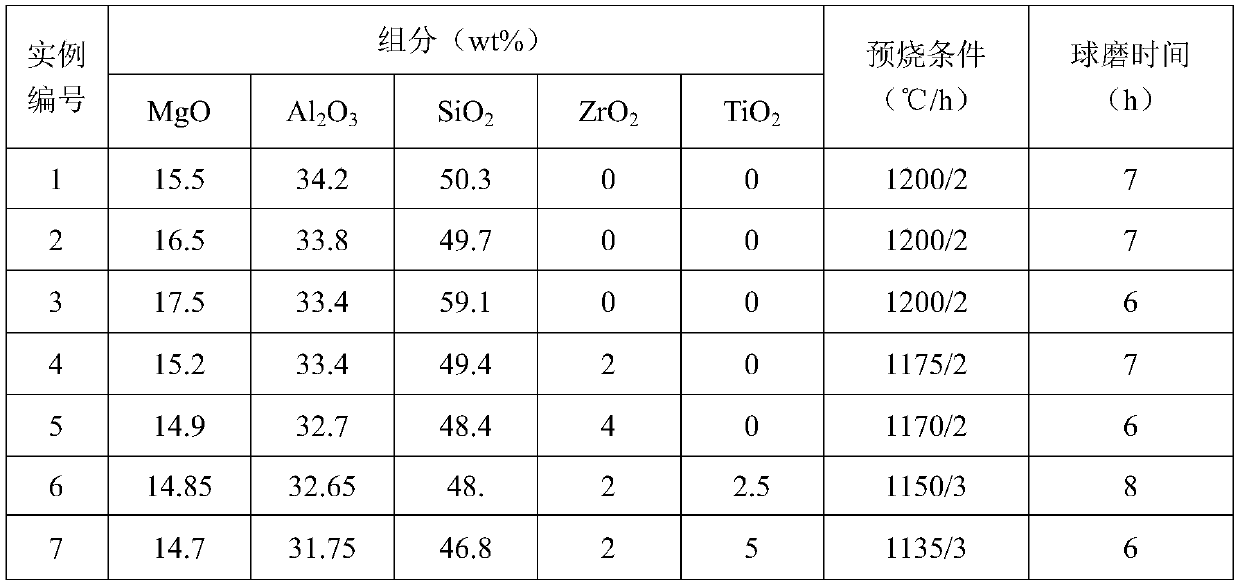

[0022] A method for preparing a cordierite microwave dielectric ceramic material, characterized in that it comprises the following steps:

[0023] The first step: according to the MgO and Al in Table 1 2 o 3 , SiO 2 Calculate the actual amount of the mass percentage, weigh, mix, and ball mill in deionized water for 6 to 8 hours; the powder after ball milling is dried and passed through a 120 mesh sieve, and the obtained dry powder is placed in a crucible and ground at 1100 Pre-fire at a temperature of ~1200°C for 2-3 hours to obtain pre-fired material;

[0024] Second step: calculate ZrO by mass percentage in Table 1 2 、TiO 2 After weighing the material, add it to the calcined material obtained in the first step, ball mill for 5-8 hours, after drying, add the binder PVA for granulation, dry press molding under the pressure of 30MPa, and the obtained embryo The body is sintered at 1350-1450° C. for 2-3 hours to obtain a cordierite microwave dielectric ceramic material. Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com