Preparation method of high-purity aluminum oxide

A high-purity alumina and aluminum hydroxide technology, applied in the preparation of alumina/hydroxide, etc., can solve the problems of easy fire and explosion, large equipment investment, complex production process, etc., to prevent the entry of impurities and pollution-free The effect of strong controllability of waste emissions and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

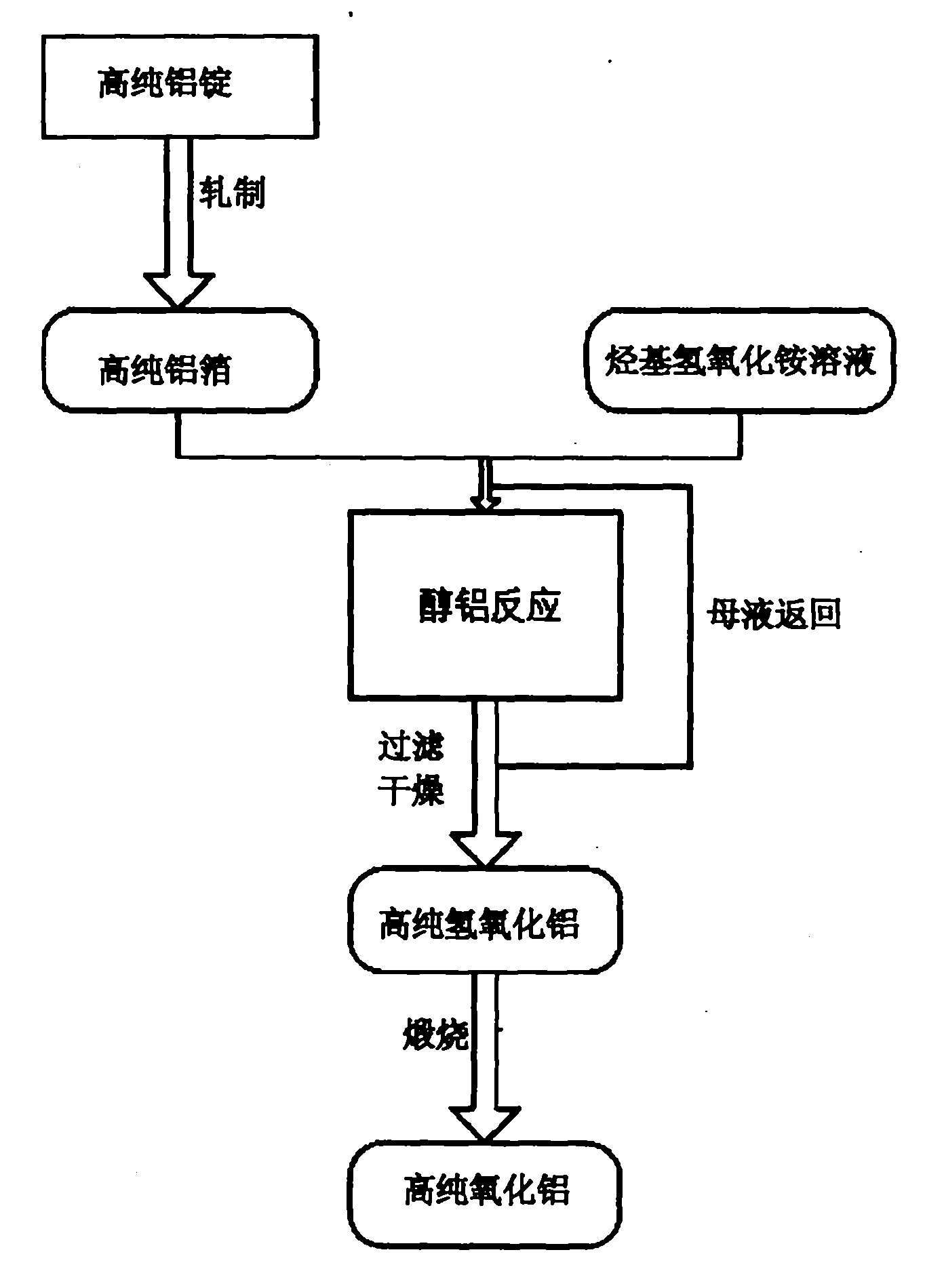

[0027] The invention provides a method for preparing high-purity alumina, comprising: reacting high-purity aluminum with a purity greater than 99.99% and an electronic-grade hydrocarbyl ammonium hydroxide solution to form an aluminum organic double salt, and hydrolyzing the formed aluminum organic double salt to form hydroxide Aluminum; the generated aluminum hydroxide is filtered, such as vacuum filtered, washed with pure water and dried at a temperature of 100-200°C to obtain high-purity aluminum hydroxide with a purity of 99.999% or more; the dried high-purity aluminum hydroxide is passed through Calcined at high temperature to obtain high-purity alumina with a purity above 99.999%.

[0028] The high-purity aluminum in the present invention refers to aluminum with a purity of more than 99.99%. In order to obtain high-purity aluminum raw materials with high activity, no pollution and favorable reaction, high-purity aluminum ingots (5N grade) can be rolled to obtain high-puri...

Embodiment 1

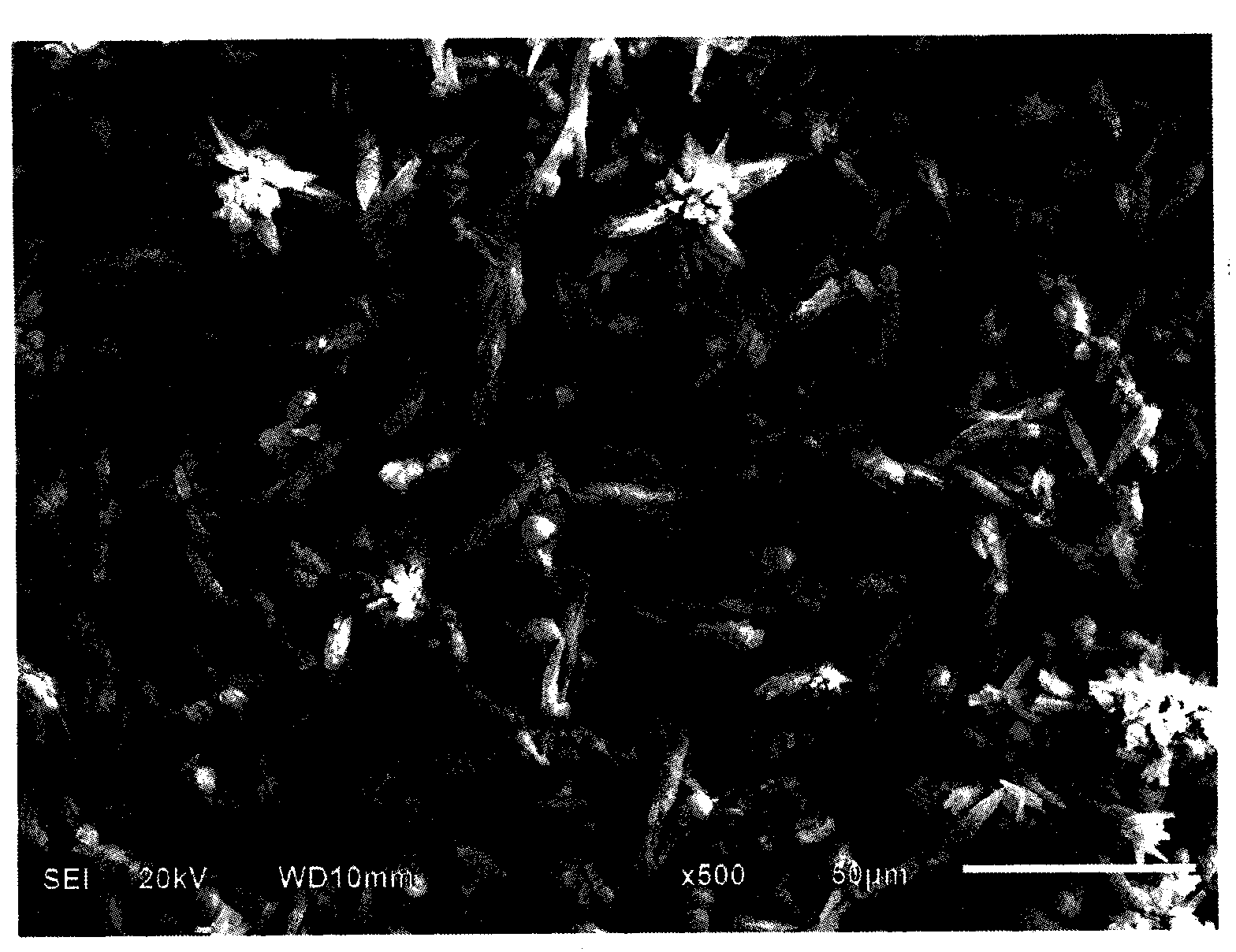

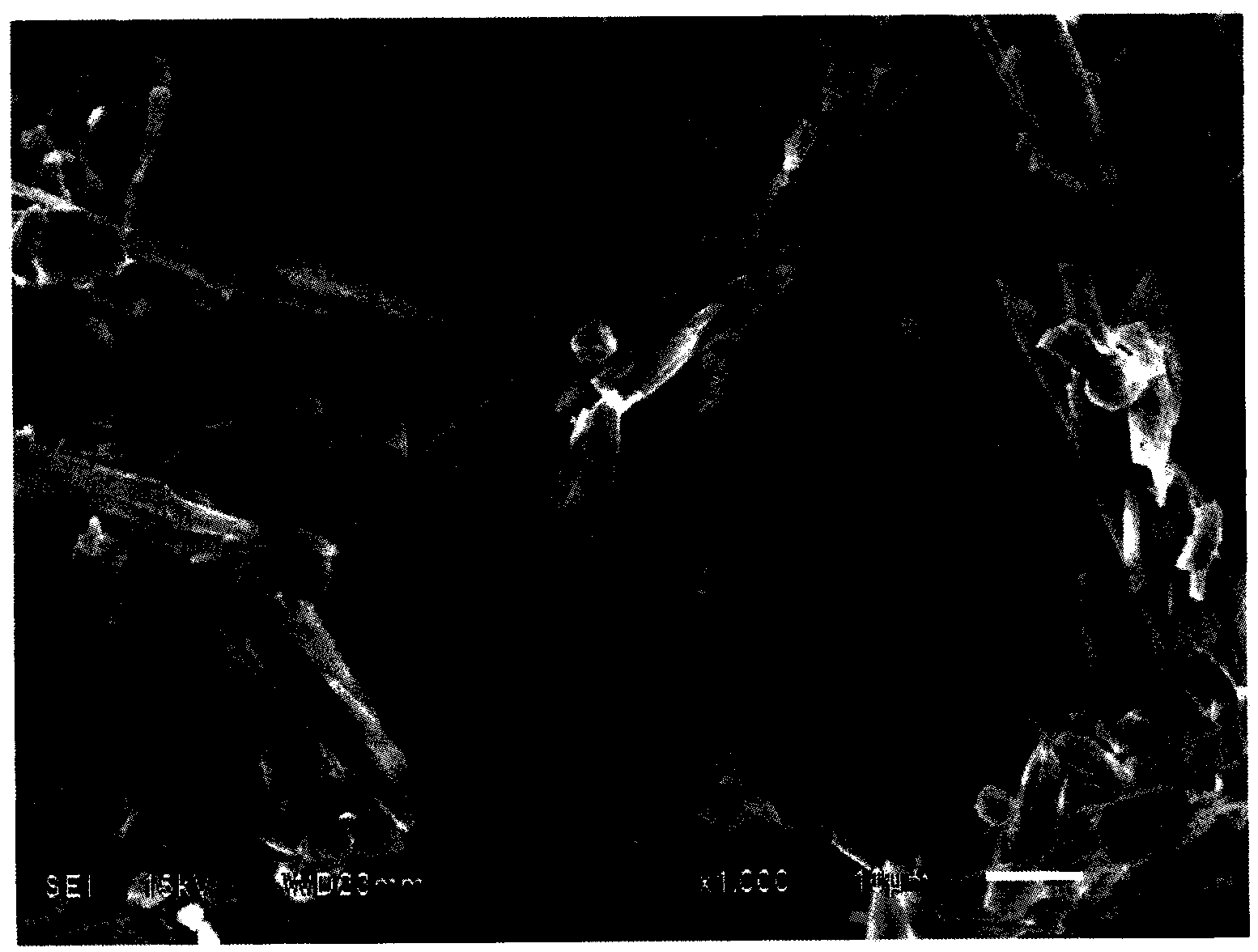

[0044] In the polytetrafluoroethylene reaction container of 500L, add the high-purity aluminum foil (Nantong Taide, purity 5N) that 5kg thickness is 5um, 300L concentration is the electronic grade tetramethylammonium hydroxide solution of 5wt% (Runjing chemical industry, electronic Grade TMAH) reacted at a temperature of 20°C. After 5 hours of reaction, almost no gas was released, and the reaction ended. The aluminum hydroxide precipitate is discharged from the reaction vessel, and after vacuum filtration, the mother liquor is returned to the reaction vessel to continue to participate in the reaction. The filtered aluminum hydroxide solid is washed with pure water and then dried in vacuum at a temperature of 100°C. The dried aluminum hydroxide powder was calcined at a temperature of 750° C. to finally obtain 3.5 kg of alumina powder. Its purity was tested to be greater than 99.999%, and the test results are shown in Table 1.

Embodiment 2

[0046] In a 500L polytetrafluoroethylene reaction vessel, add 5kg of high-purity aluminum foil with a thickness of 20um, and 240L of the mother liquor returned from Example 1, and react at a temperature of 60°C. After 3.5 hours of reaction, almost no gas was released, and the reaction ended. The precipitated aluminum hydroxide was drained from the reaction vessel. The mother liquor after aluminum hydroxide precipitation and filtration can be returned to the reaction vessel to continue to participate in the reaction, and the filtered aluminum hydroxide solid is washed with pure water and then dried in vacuum at a temperature of 200°C. The dried aluminum hydroxide powder was calcined at a temperature of 1300° C. to finally obtain 8.75 kg of alumina powder. Its purity is greater than 99.999% after inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com