Low-temperature-sintered composite microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature sintering, applied in the field of electronic ceramics and its manufacturing, can solve the problems of high sintering temperature and inability to co-fire low-melting point metals, etc., and achieve the effect of excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

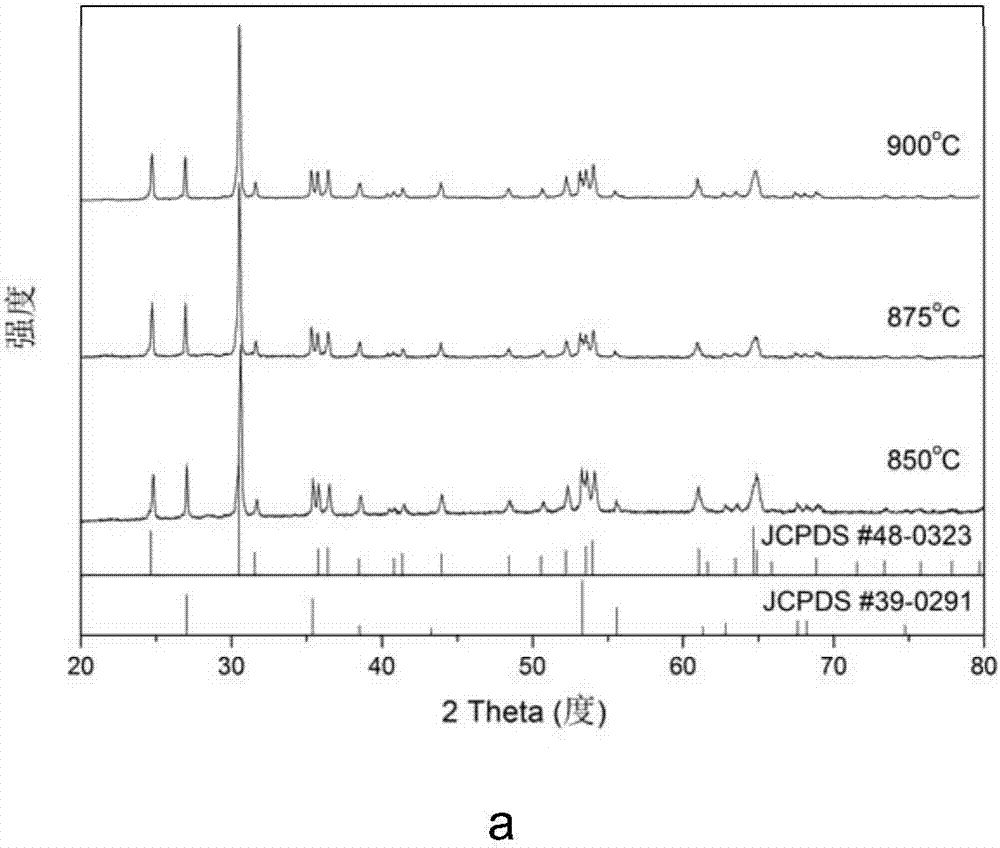

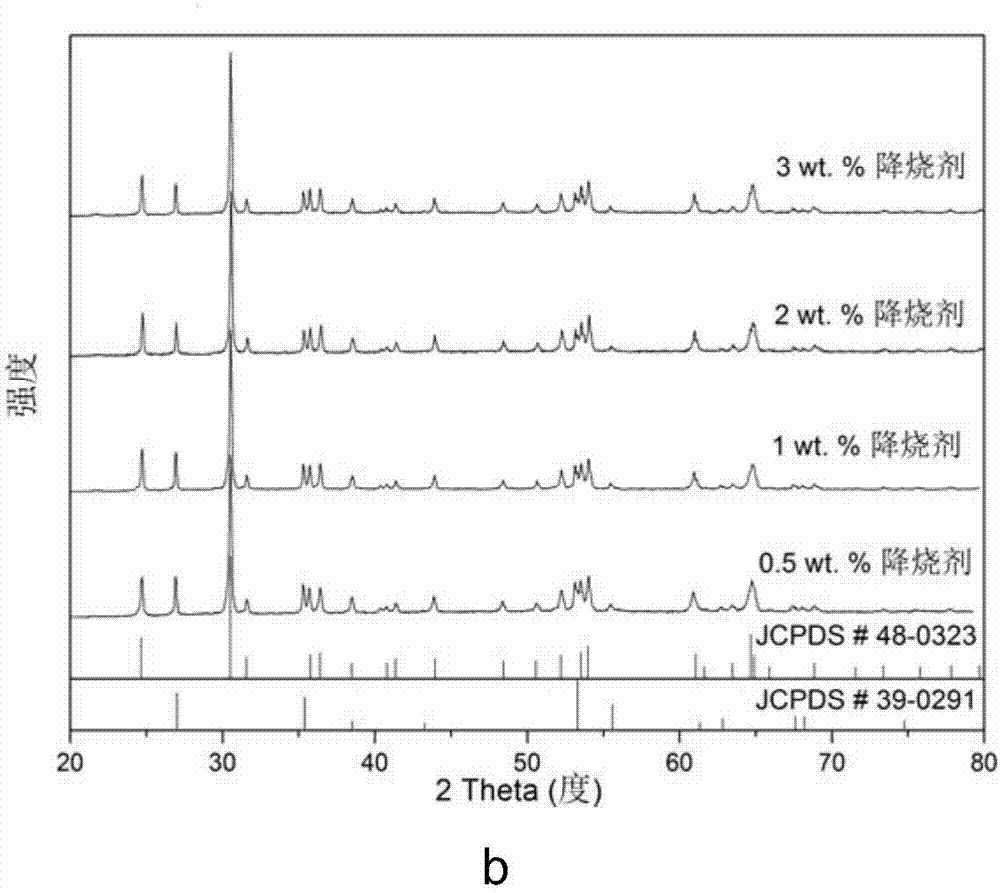

[0022] (Zn 1-x co x ) 0.5 Ti 0.5 (Nb 1-y Ta y )O 4 , x=0.3, y=0.4.

[0023] Step 1. Mix the ingredients according to the parameters in the table, grind the planetary ball for 6 hours according to the mass ratio of powder: zirconium ball: deionized water 1:5:2, then dry at 100°C, sieve with a 60-mesh sieve, and finally Pre-fired for 3 hours in the air atmosphere at 1000°C.

[0024] Step 2. Mix the raw materials of the fever reducer according to the parameters in the table, ball mill for 7 hours, dry and sieve, pre-fire at 800°C for 3 hours, then heat at 1200°C for 3 hours to melt the glass slag, and crush the glass slag into powder Produce a fever reducer.

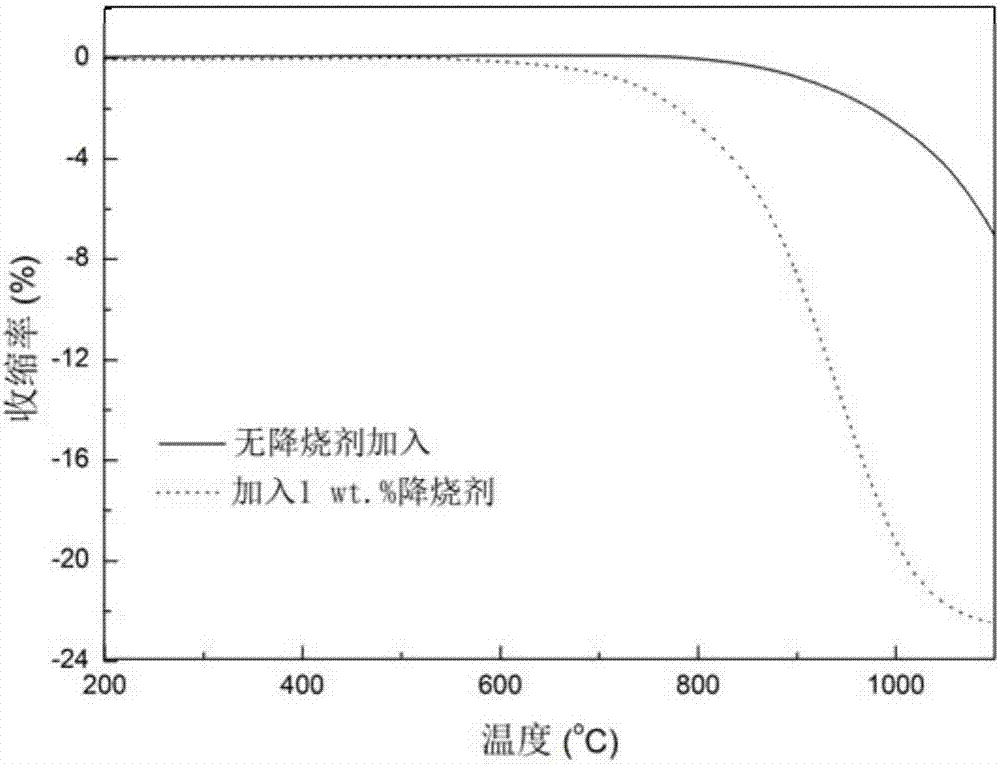

[0025] Step 3. Add the prepared fever reducer powder to the pre-fired material according to the mass percentage of 0.5-3wt.% of the pre-fired material, and perform secondary ball m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com