Microwave dielectric ceramic material and preparation method therefor

A microwave dielectric ceramic and ceramic technology, which is applied in the field of electronic ceramics, can solve the problems of high dielectric loss, high sintering cost, and cannot meet the requirements of low insertion loss microwave devices, and achieves the effect of small temperature coefficient of resonant frequency and high quality factor Qf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

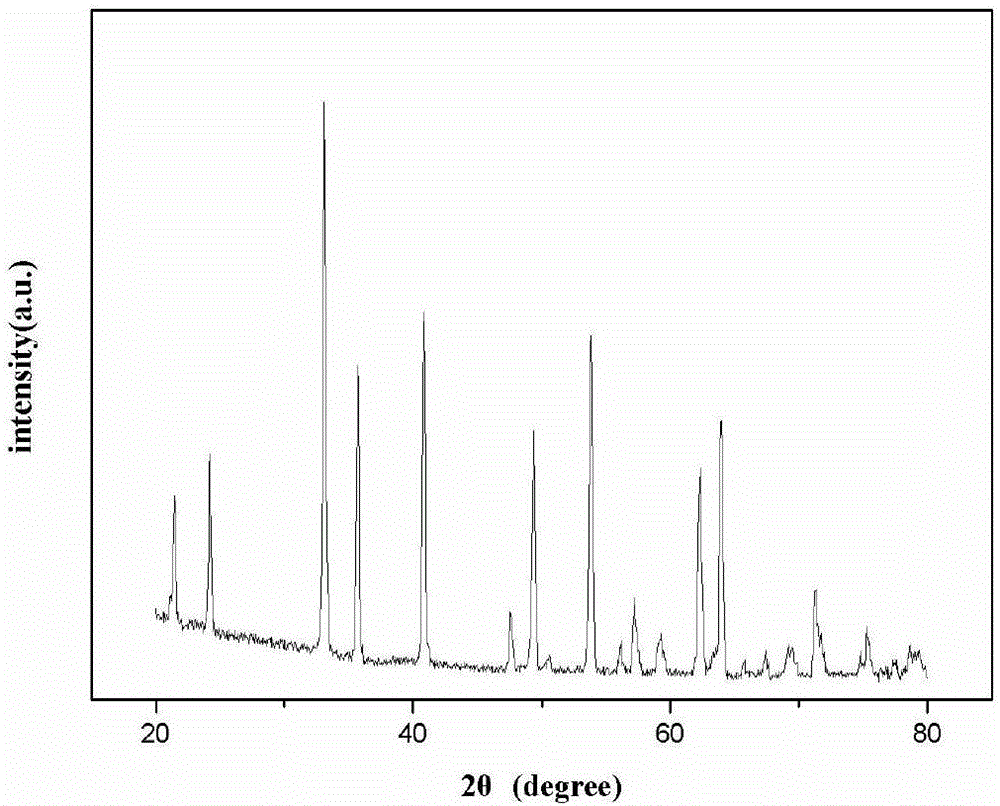

Embodiment 1

[0035] A common calcium-doped (MgCa)TiO 3 The preparation method of system ceramics, concrete steps are as follows:

[0036] Step 1: batching; Magnesium carbonate basic (4MgCO 3 ·Mg(OH) 2 5H2O) powder, calcium oxide (CaO) powder and titanium oxide (TiO2) powder are 4MgCO in molar ratio 3 ·Mg(OH) 2 ·5H 2 O: CaO: TiO 2 = 19:5:100 component batch to form 100 grams of (Mg 0.95 Ca 0.05 )TiO 3 The mixture; the mixture is deionized water as a solvent, ball milling and mixing for 6 hours to obtain a ceramic slurry;

[0037] Step 2: Dry the ceramic slurry prepared in Step 1 and pre-fire to obtain ceramic material, the pre-fire temperature is 950°C, and the pre-fire time is 5 hours;

[0038] Step 3: ball milling and mixing; do not add any composite dopant to the ceramic material obtained in step 2, use deionized water as a solvent, and ball mill and mix for 6 hours to obtain a ball mill;

[0039] Step 4: granulation and molding; drying the ball abrasive obtained in step 3, add...

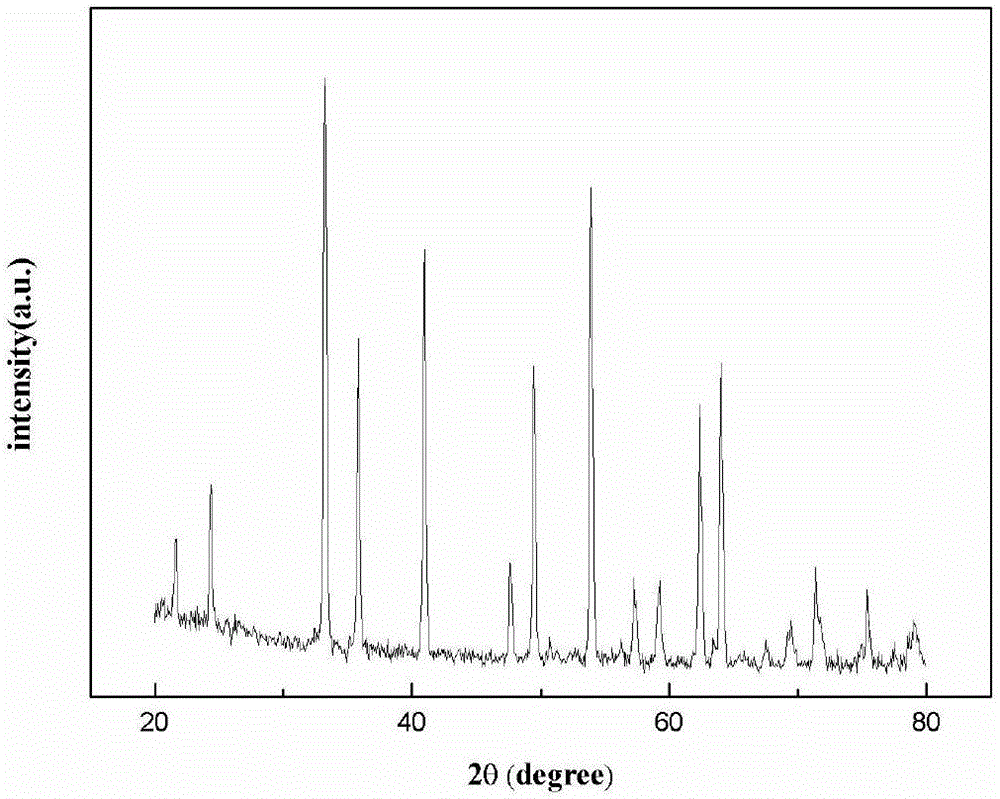

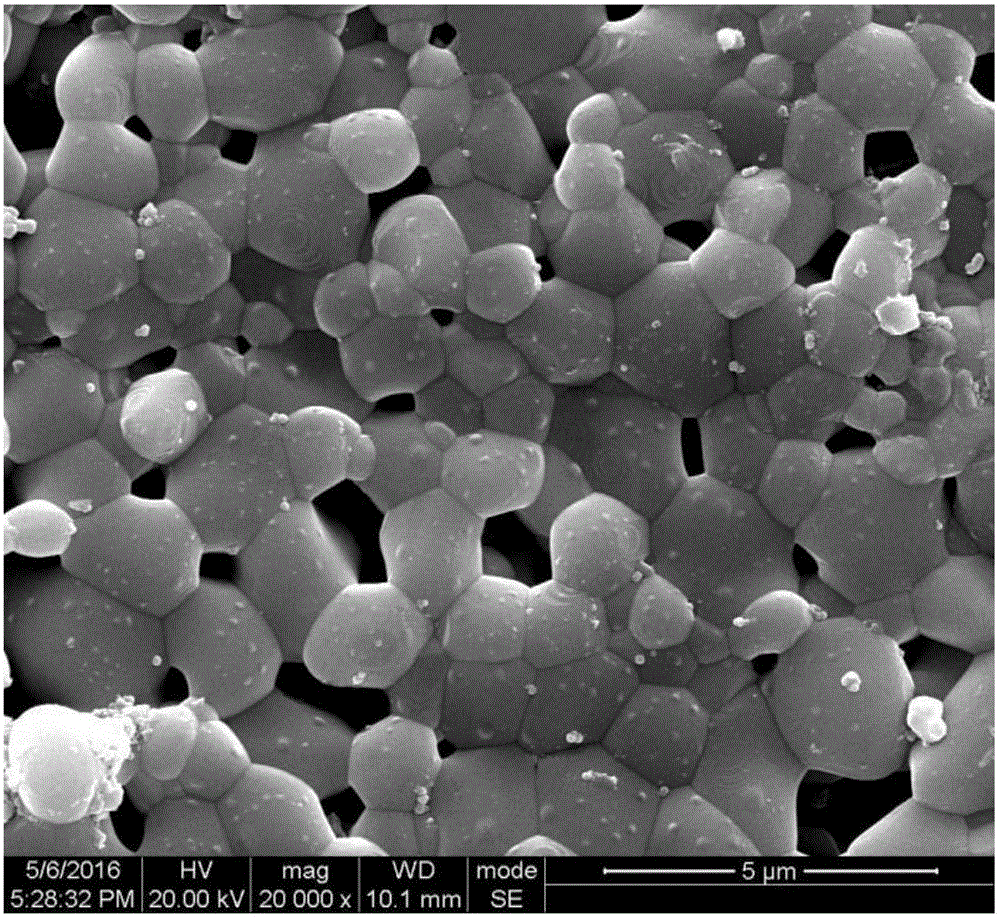

Embodiment 2

[0042] A preparation method of a microwave dielectric ceramic material, the specific steps are as follows:

[0043] Step 1: batching; Magnesium carbonate basic (4MgCO 3 ·Mg(OH) 2 ·5H 2 O) powder, calcium oxide (CaO) powder and titanium oxide (TiO 2 ) powder is 4MgCO in molar ratio 3 ·Mg(OH) 2 ·5H 2 O: CaO: TiO 2 = 19:5:100 component batch to form 100 grams of (Mg 0.95 Ca 0.05 )TiO 3 The mixture; the mixture is deionized water as a solvent, ball milling and mixing for 5 hours to obtain ceramic slurry;

[0044] Step 2: Dry the ceramic slurry prepared in step 1 and pre-fire to obtain ceramic material, the pre-fire temperature is 1000°C, and the pre-fire time is 6 hours;

[0045] Step 3: ball milling and mixing; add 0.38 grams of Nd to the ceramic material obtained in step 2 2 o 3 , 0.5 grams of ZnO and 0.12 grams of Al 2 o 3 Composite dopant formed, using deionized water as solvent, ball milling and mixing for 5 hours to mix evenly to obtain ball milling material; ...

Embodiment 3

[0049] A preparation method of a microwave dielectric ceramic material, the specific steps are as follows:

[0050] Step 1: batching; Magnesium carbonate basic (4MgCO 3 ·Mg(OH) 2 ·5H 2 O) powder, calcium oxide (CaO) powder and titanium oxide (TiO 2 ) powder is 4MgCO in molar ratio 3 ·Mg(OH) 2 ·5H 2 O: CaO: TiO 2 = 19:5:100 component batch to form 100 grams of (Mg 0.95 Ca 0.05 )TiO 3 The mixture; the mixture is deionized water as a solvent, ball milling and mixing for 5 hours to obtain ceramic slurry;

[0051] Step 2: Dry the ceramic slurry prepared in Step 1 and pre-fire to obtain ceramic material, the pre-fire temperature is 950°C, and the pre-fire time is 5 hours;

[0052] Step 3: ball milling and mixing; add 0.76 grams of Nd to the ceramic material obtained in step 2 2 o 3 , 0.5 grams of ZnO and 0.5 grams of Al 2 o 3 Composite dopant formed, using deionized water as solvent, ball milling and mixing for 6 hours to mix uniformly to obtain ball milling material; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com