Industrialization preparation of sphere-like porous silver powder

A porous silver and spherical-like technology, applied in the field of porous metal materials, can solve the problems of small effective reaction surface area, short service life, high service life, etc., and achieve the effect of easy control, high yield and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

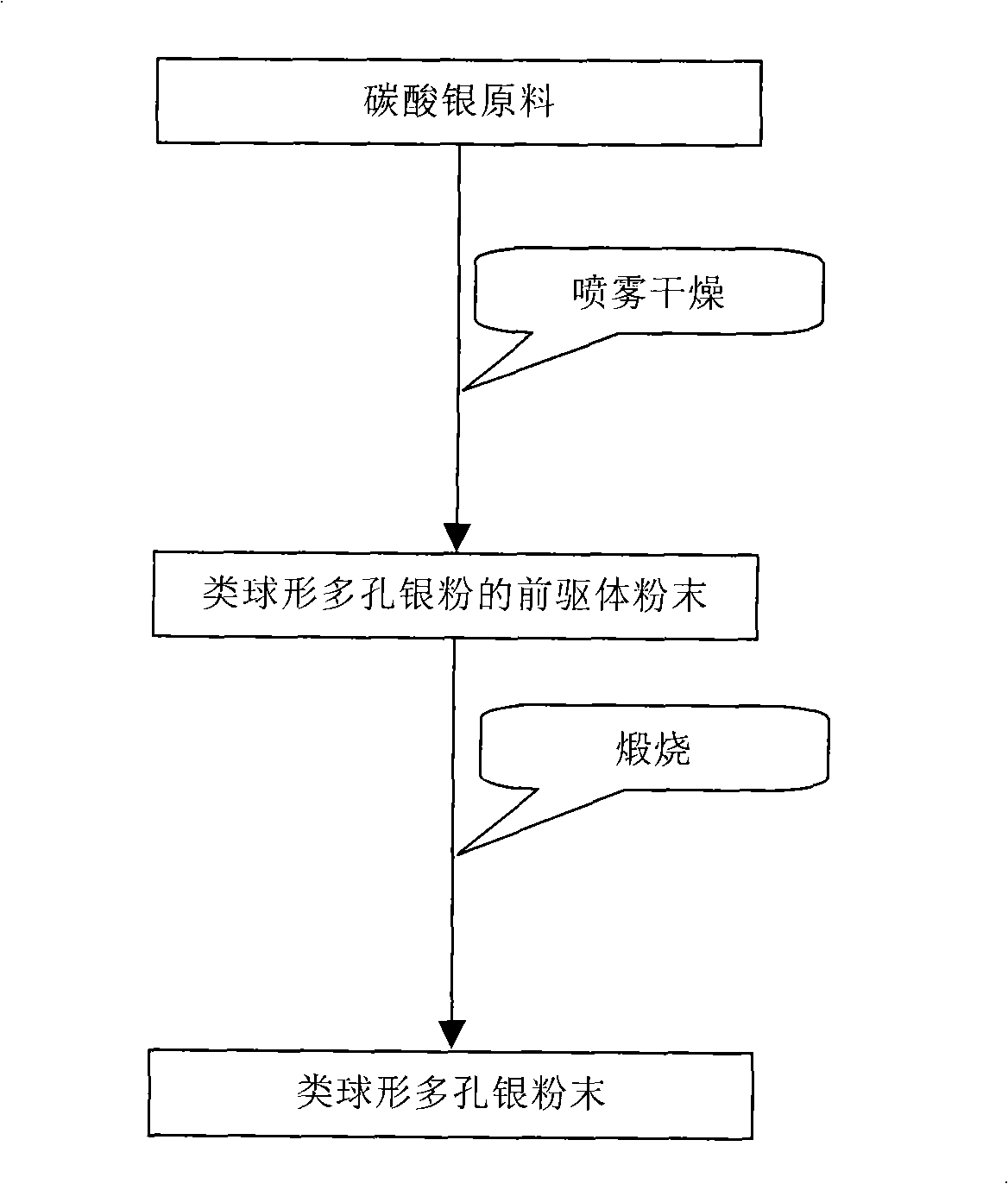

Method used

Image

Examples

Embodiment 1

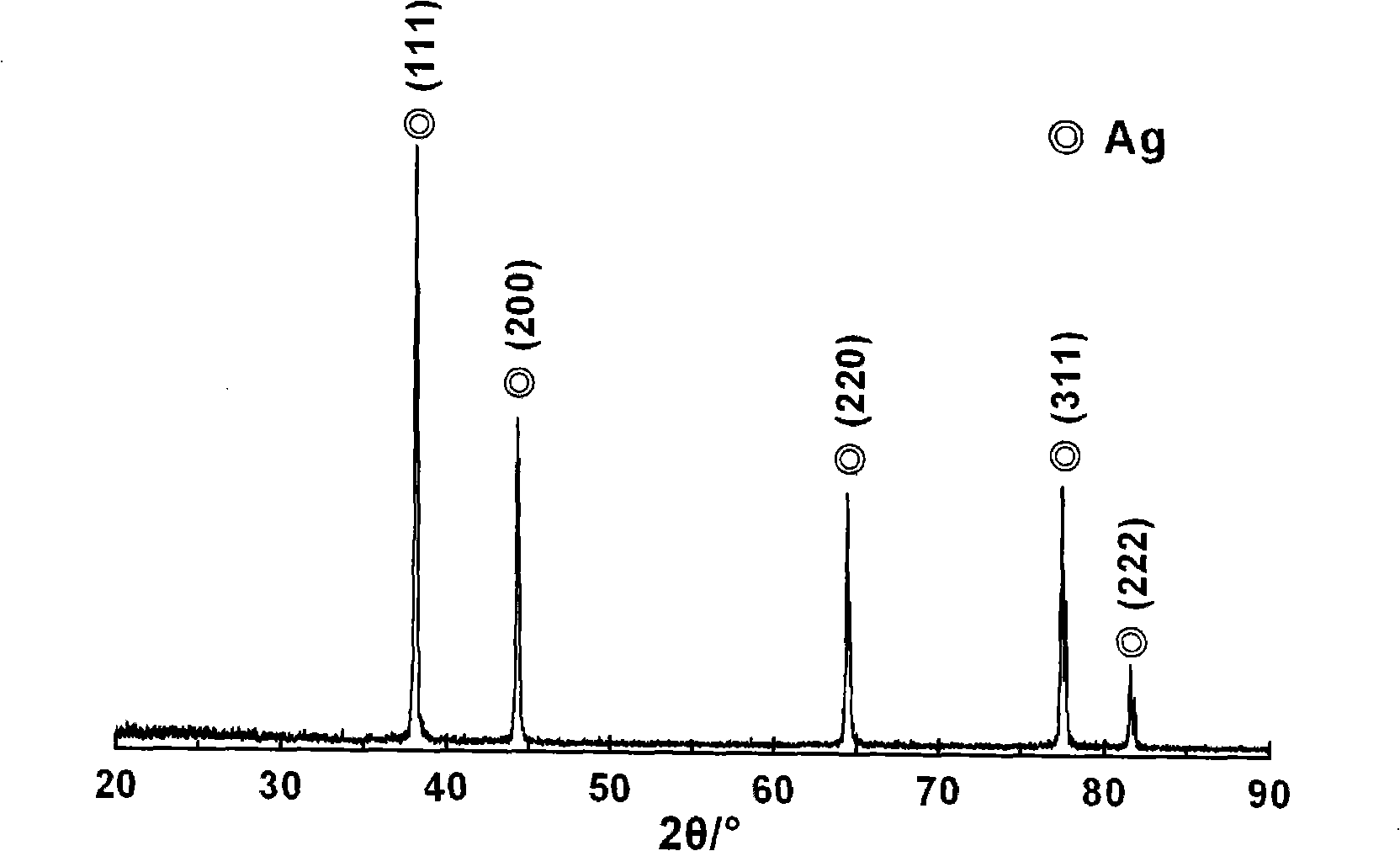

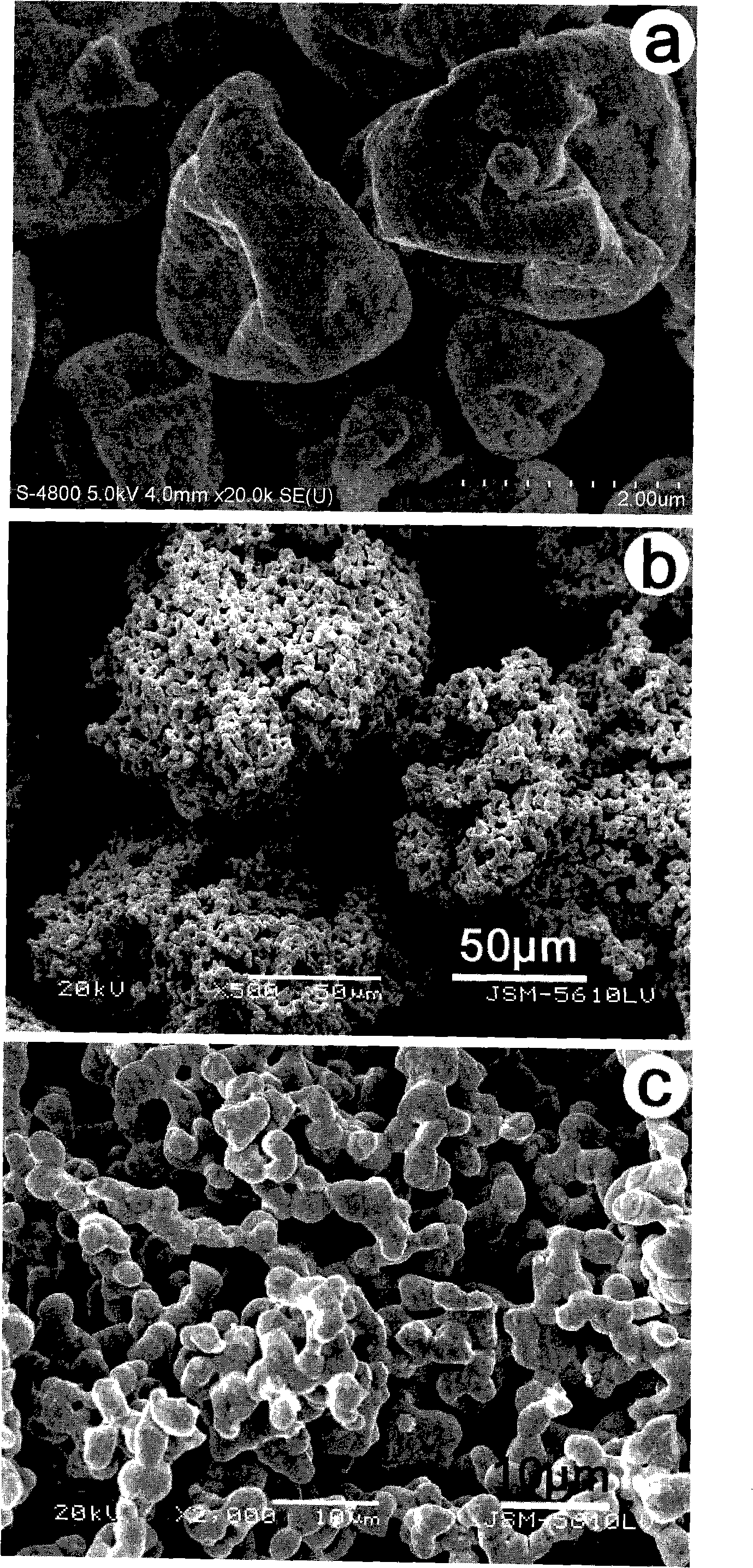

[0035] 50 g silver carbonate Ag 2 CO 3 The raw material is dissolved in 950 ml of ammonia solution with a concentration of 5wt.%, spray-dried in an air atmosphere, the flow rate of the solution is 1000 ml / hour, the flow rate of the carrier gas is 0.28 MPa, the air inlet temperature is controlled at 280 ° C, and the air outlet temperature is controlled at 180 ° C The precursor powder of the quasi-spherical porous silver powder is made; the precursor powder of the obtained quasi-spherical porous silver powder is placed in an alumina crucible, calcined under an air atmosphere, the calcining temperature is 400 ° C, and the calcining time is 40 minutes. The calcining process is: First, the temperature was raised to 100°C at a heating rate of 5°C / min, and kept for 10 minutes; the temperature was raised from 100°C to 150°C at a heating rate of 2°C / min, and kept for 30 minutes; Raise the temperature to 200°C and keep it warm for 10 minutes; raise the temperature from 200°C to 260°C a...

Embodiment 2

[0038] 62 g silver nitrate AgNO 3 Prepared into a solution and reacted with an appropriate amount of sodium carbonate to prepare Ag 2 CO 3 Raw materials, after fully reacting, carry out suction filtration and washing to obtain Ag 2 CO 3 Raw material, it is dissolved in 950ml concentration and is 20wt.% ammonia solution, spray drying in air atmosphere, solution flow rate is 400 ml / hour, carrier gas flow rate 0.32MPa, air inlet temperature is controlled at 250 ℃, air outlet temperature is controlled at 120 ℃ to make the precursor powder of spherical porous silver powder; put the obtained spherical porous silver powder precursor powder in an alumina crucible, and calcined under air atmosphere, the calcination temperature is 400 ℃, the calcination time is 10 minutes, and the calcination process is : First, the temperature was raised to 100°C at a heating rate of 5°C / min, and kept for 10 minutes; the temperature was raised from 100°C to 150°C at a heating rate of 2°C / min, and ke...

Embodiment 3

[0040] 310 g silver nitrate AgNO 3 Prepared into a solution and reacted with an appropriate amount of sodium bicarbonate to prepare Ag 2 CO 3 Raw materials, after fully reacting, carry out suction filtration and washing to obtain Ag 2 CO 3 The raw material is dissolved in 750ml of ammonia solution with a concentration of 5wt.%, spray-dried in an air atmosphere, the flow rate of the solution is 800 ml / hour, the flow rate of the carrier gas is 0.29MPa, the air inlet temperature is controlled at 280°C, and the air outlet temperature is controlled The precursor powder of the quasi-spherical porous silver powder is made at 180°C; the precursor powder of the quasi-spherical porous silver powder is placed in an alumina crucible, and calcined under a nitrogen atmosphere, the calcining temperature is 600°C, and the calcining time is 20 minutes. The process is as follows: first, the temperature is raised to 100°C at a heating rate of 5°C / min, and the temperature is kept for 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com