Microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and mass fraction technology, applied in the field of information functional materials, can solve the problems of unstable performance and high dielectric constant ε, and achieve the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the above-mentioned microwave dielectric ceramic material, comprising the following steps:

[0029] ① Preparation of Mg as one of the main materials 2-3x Ca x TiO 4-2x Powder: according to the ratio of each metal element in the compound, weigh the corresponding quality of high-purity, ultra-fine Mg(OH) 2 , CaCO 3 、TiO 2 , placed in a ball mill, according to the mass ratio of solid material: water = 1: (1.0 ~ 2.0), add water to carry out ball milling and mix evenly, after the sand milling treatment reaches a certain particle size, use a spray drying tower or other methods to dry, Calcined in an air atmosphere furnace at a temperature range of 1050°C to 1300°C for 2 to 4 hours to finally obtain Mg 2-3x Ca x TiO4-2x powder. Among them, Mg(OH) 2 The specific surface area is greater than 7.0m 2 / g,TiO 2 The specific surface area is greater than 5.0m 2 / g.

[0030] ② Preparation of another component of CaS...

Embodiment

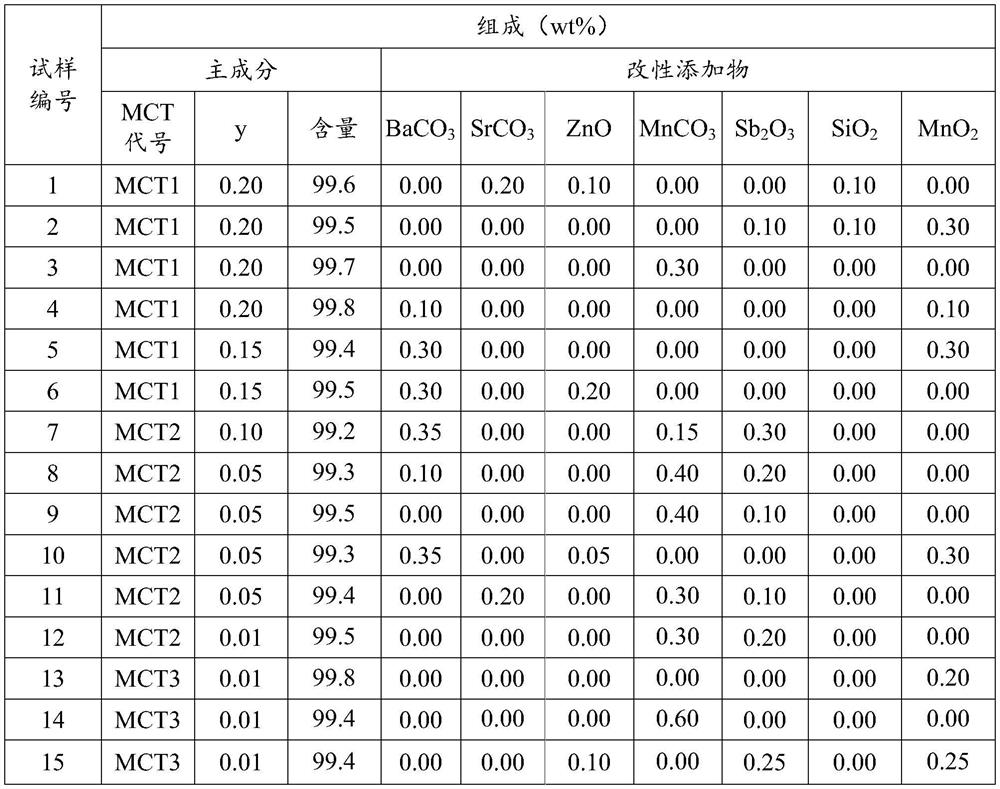

[0041] This embodiment provides a microwave dielectric ceramic material and a preparation method thereof, and the solution of the present invention is not limited to the embodiment.

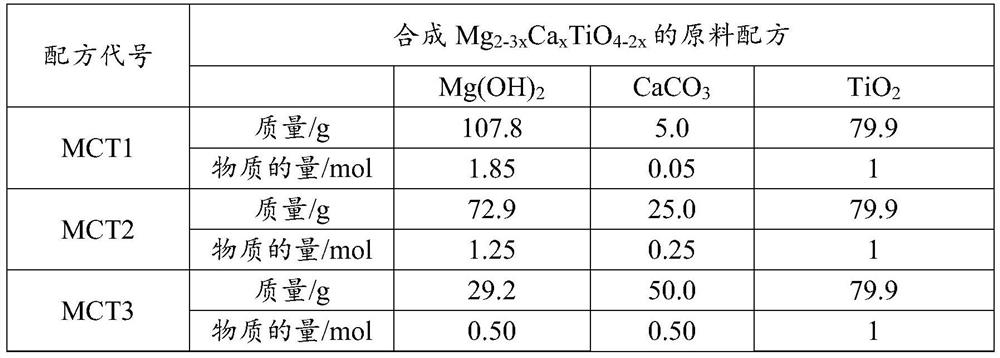

[0042] (1) According to Mg 2-3x Ca x TiO 4-2x Composition, wherein 0.01≤x≤0.50, the raw material formula shown in Table 1, weigh three groups of Mg(OH) with corresponding mass 2 , CaCO 3 and TiO 2 , placed in the ball mill in turn, according to the mass ratio of each group of solid materials: deionized water = 1:1.5, add deionized water for wet ball milling, after ball milling, use a spray drying tower to dry, and calcined in an air furnace at 1200 ° C 3 hours. In each group of samples: in MCT1, x=0.05; in MCT2, x=0.25; in MCT3, x=0.50.

[0043] Table 1 Mg 2-3x Ca x TiO 4-2x Example formulation

[0044]

[0045] (2) According to CaSiO 3 Composition, calcium carbonate and silicon dioxide are arranged in the ball mill according to the molar ratio of 1:1, according to the ratio of soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Qf | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com