ZnTiNb2O8-series microwave dielectric ceramic material and preparing method thereof

A technology of microwave dielectric ceramics and solid phase method, which is applied in the field of ZnTiNb2O8 series microwave dielectric ceramic materials and its preparation, can solve the problems of microwave dielectric property degradation, achieve good microwave performance, simple process, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

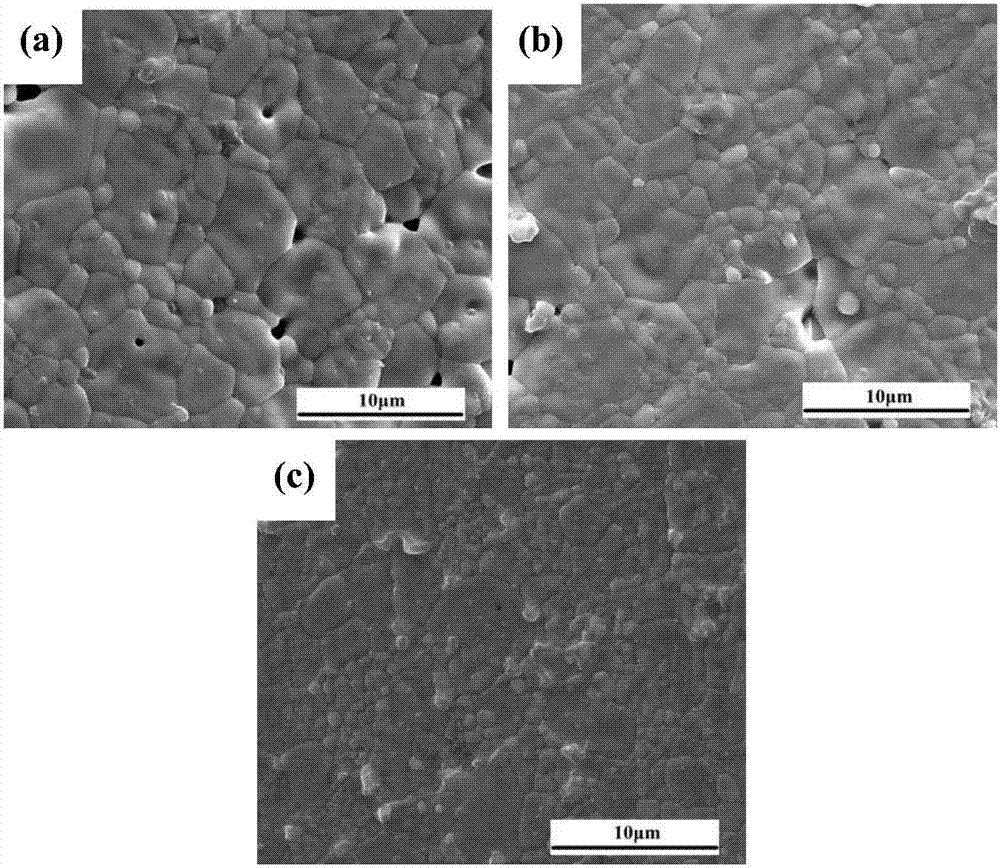

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

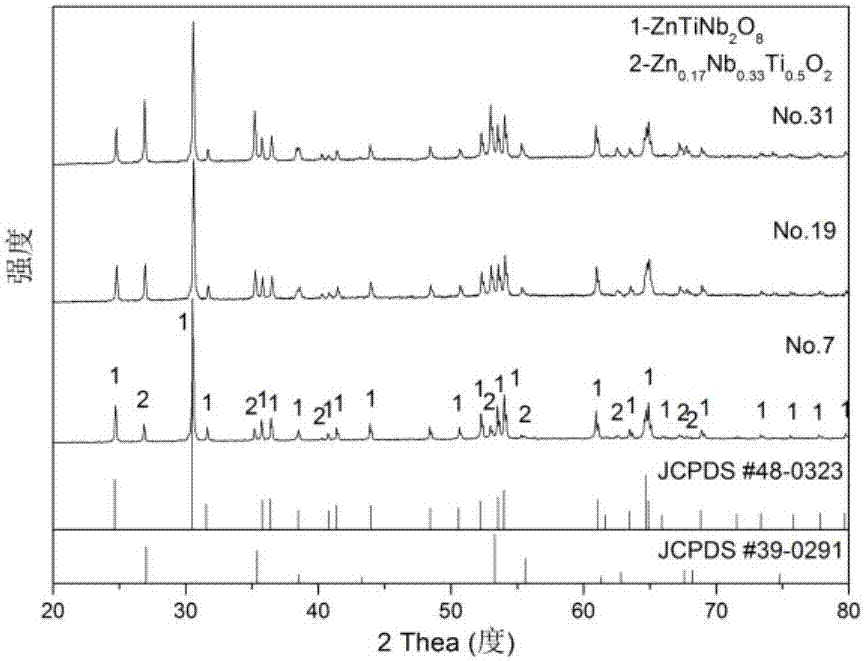

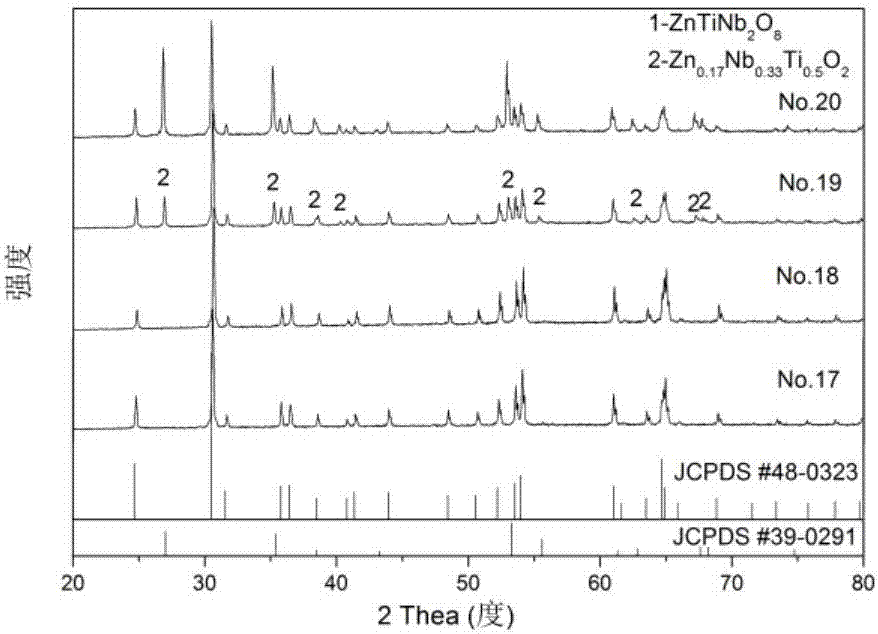

[0017] Step 1, ZnO, Co 2 o 3 、TiO 2 , Nb 2 o 5 and Ta 2 o 5 The original powder according to the general chemical formula (Zn 1-x co x ) 0.5 Ti 0.5 (Nb 1-y Ta y )O 4 (0≤x≤0.3mol, y=0.2-0.4mol) ingredients.

[0018] Step 2. Add the powder obtained in step 1 into a nylon tank according to the mass ratio of powder: zirconia ball: deionized water 1:5:2, mix with a planetary ball mill for 6 hours, take it out and dry it at 100°C to Sieve through a 60-mesh sieve, and then pre-fire in the atmosphere at 1000°C for 3 hours to synthesize the main crystal phase ZnTiNb 2 o 8 .

[0019] Step 3. Add the powder obtained after pre-calcining in step 2 into the nylon tank according to the mass ratio of powder: zirconia ball: deionized water 1:5:1, mix it with a planetary ball mill for 4 hours, take it out and bake it at 100°C After drying, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com