Method for preparing BaTiO3-SrTiO3 miscible ceramic powder

A ceramic powder, mixed-phase technology, applied in ceramics, inorganic insulators, etc., can solve the problems of contact state distribution, complex reaction, etc., and achieve the effect of superior electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

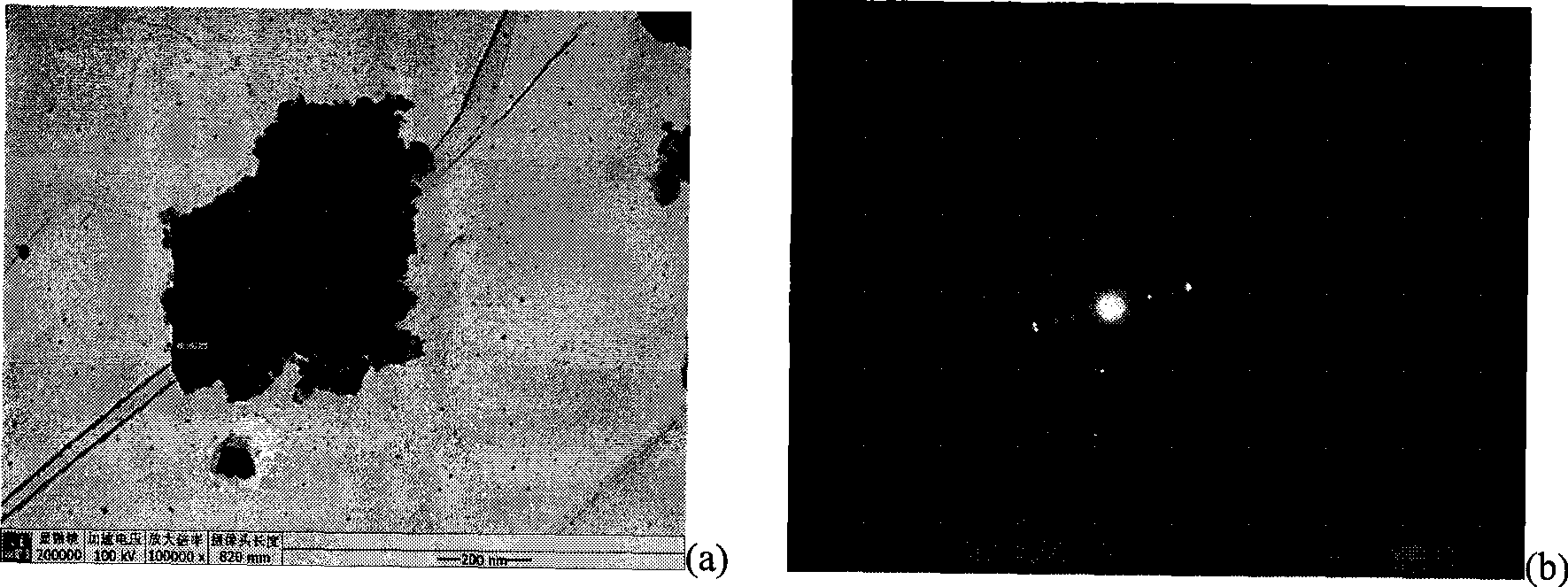

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation process and steps in this embodiment are as follows:

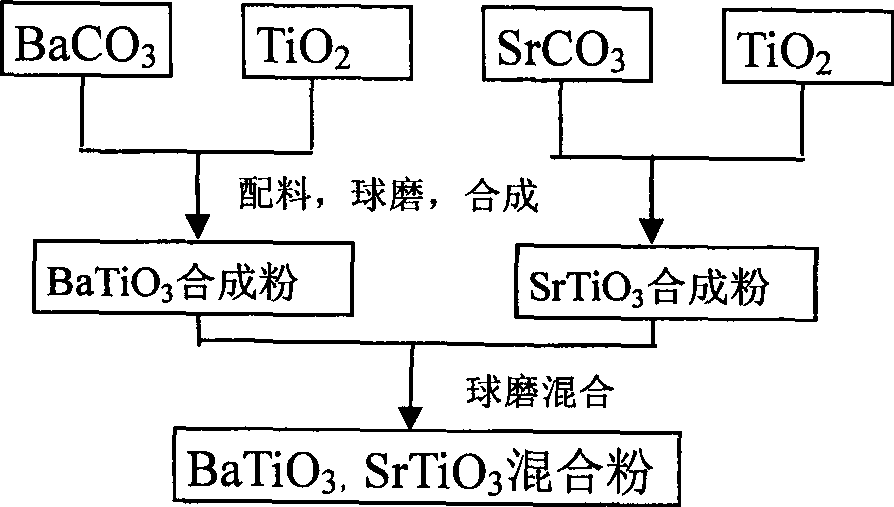

[0024] 1. Solid state reaction synthesis of BaTiO 3 -SrTiO 3 Matrix powder

[0025] (1) Using analytically pure principle BaCO 3 , SrCO 3 , TiO 2 , weigh the above three raw materials according to the required stoichiometric ratio; first weigh a certain amount of BaCO 3 with a certain amount of TiO 2 Put the ingredients into a ball mill tank, add an appropriate amount of deionized water and anhydrous ethanol, and continue ball milling for 24 hours; in addition, a certain amount of SrCO 3 with a certain amount of TiO 2 Put the ingredients into a ball milling tank, add an appropriate amount of deionized water and anhydrous ethanol, and perform continuous ball milling for 24 hours; the weight of the ball milling medium put in during ball milling is 1.2 times the weight of the raw materials used;

[0026] (2) Put the above-mentioned two kinds of ball-milled slurries into a clean por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com