High-temperature thermal shock resistant aluminum oxide ceramic burning loading plate and preparation process thereof

A technology of alumina ceramics and thermal shock resistance, which is applied in the field of refractory materials, can solve the problems of poor thermal shock resistance and low average cycle rate, and achieve the effects of good thermal shock resistance, improved fluidity, and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

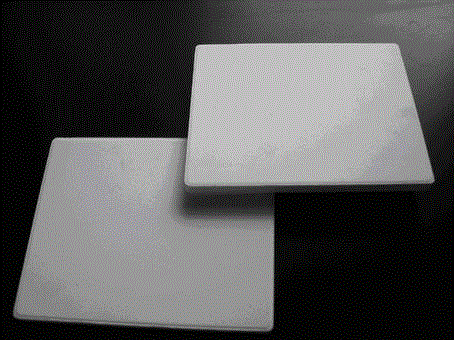

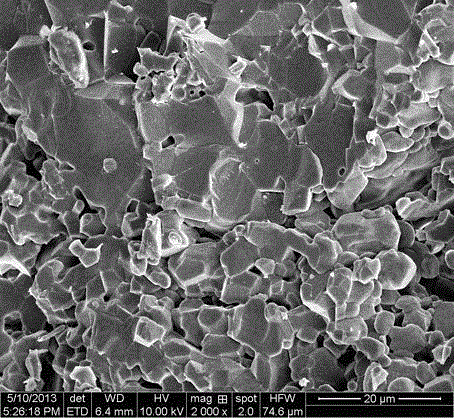

Image

Examples

Embodiment 1

[0024] Prepare raw materials according to 20 parts of alumina microspheres, 80 parts of alumina ceramic powder, 0.3 parts of sintering aid, and 5 parts of binder (PVA); mix the raw materials in the ball mill for dry ball milling 6 Hours, the powder is stale for one day after the powder is prepared; the prepared powder is passed through a 60-200 mesh sieve, dry-pressed under a pressure of 100 MPa, dried to a moisture content of less than 0.5%, and then traditionally pressureless sintered in a resistance furnace to sinter The temperature is 1600°C; the firing temperature system is to first raise the temperature to 100°C at a heating rate of 1°C / min, keep it for 120 minutes, and then raise the temperature to 50°C before the firing temperature at a heating rate of 1°C / min, then change to slow firing 200 minutes to firing temperature, heat preservation 120min.

[0025] The setter plate prepared in this example has a bulk density of 3.4028 g / cm3, a flexural strength of 146.157 MPa, ...

Embodiment 2

[0027] The present invention prepares raw materials according to 30 parts by weight of alumina ceramic granulation powder, 70 parts by weight of alumina ceramic powder, 0.5 parts of sintering aid, and 5 parts by weight of binder (PVA); mix the raw materials in the ratio in a ball mill Ball milling by medium dry method for 10 hours, the powder is stale for one day after the powder is obtained; the prepared powder is passed through a 60-200 mesh sieve, dry-pressed under a pressure of 100 MPa, dried until the moisture is less than 0.5%, and then carried out in a resistance furnace. Pressing and sintering, the firing temperature is 1620°C.

[0028] The setter plate prepared in this example has a bulk density of 3.3016 g / cm3, a flexural strength of 126.157 MPa, and a thermal shock resistance of 84 times under the condition of 1000°C for 30 minutes and air cooling.

Embodiment 3

[0030] Prepare raw materials according to 40 parts of alumina ceramic granulation powder, 50 parts of alumina ceramic powder, 0.5 parts of sintering aid, and 5 parts of binder (PVA); mix the raw materials in the ball mill by dry method After ball milling for 10 hours, the powder is stale for one day after the powder is prepared. The prepared powder is passed through a 60-200 mesh sieve, dry-pressed under a pressure of 100 MPa, dried to a moisture content of less than 0.5%, and then subjected to traditional pressureless sintering in a resistance furnace. The firing temperature is 1640°C; the firing temperature system is to first raise the temperature to 100°C at a heating rate of 1°C / min, hold the temperature for 120 minutes, and then raise the temperature to 50°C before the firing temperature at a heating rate of 1°C / min, then slow down Burn for 200 minutes to the firing temperature and keep warm for 120 minutes.

[0031] It can be obtained with a bulk density of 3.2074 g / cm3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com