Sintering method of high-temperature co-firing aluminum nitride ceramics

A technology of aluminum nitride ceramics and sintering method, which is applied in the field of multi-chip components (MCM) and high-power ceramic substrates and shells, and can solve the problems of ceramic sintering quality decline, ceramic strength and metallization strength influence, and volatility, etc. Achieve metallization strength, avoid excessive volatilization, and meet flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

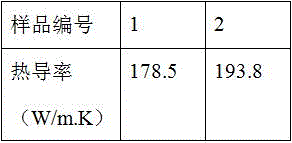

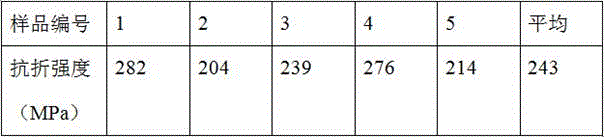

Examples

Embodiment 1

[0031] A sintering method for preparing high-temperature co-fired aluminum nitride ceramics, the method is as follows:

[0032] 1) According to the weight ratio of 80% AlN powder, 4% sintering aid (yttrium oxide, calcium oxide), 7% binder, 4% plasticizer, 5% solvent (acetone) to prepare the green porcelain slurry, through casting Process to produce AlN green ceramic parts; the surface of AlN green ceramic sheets is printed with tungsten metallization paste by printing process;

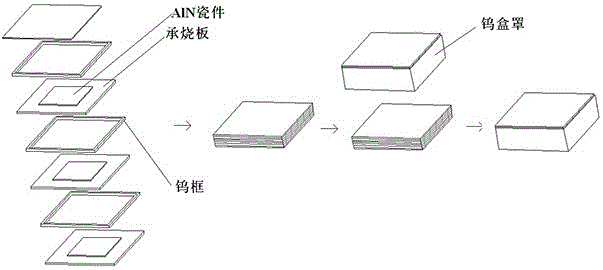

[0033] 2) A number of AlN raw porcelain pieces are laminated and hot-pressed to form a multi-layer green porcelain piece, and at the same time, some AlN green porcelain pieces are made of flexural strength and thermal conductivity through lamination, hot pressing, raw cutting or laser cutting processes Green porcelain standard samples for testing;

[0034] 3) Put the raw porcelain parts and raw porcelain standard samples on the AlN or tungsten firing plate, and put them in the debinding furnace for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com