Steel wire surface treatment defogging components

A surface treatment and defogging component technology, which is applied in the field of gas purification, can solve the problems of excessive volatilization in the pickling pool, diffuse in the workshop, defogging, etc., and achieve the effects of avoiding excessive volatilization, reasonable structural design, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

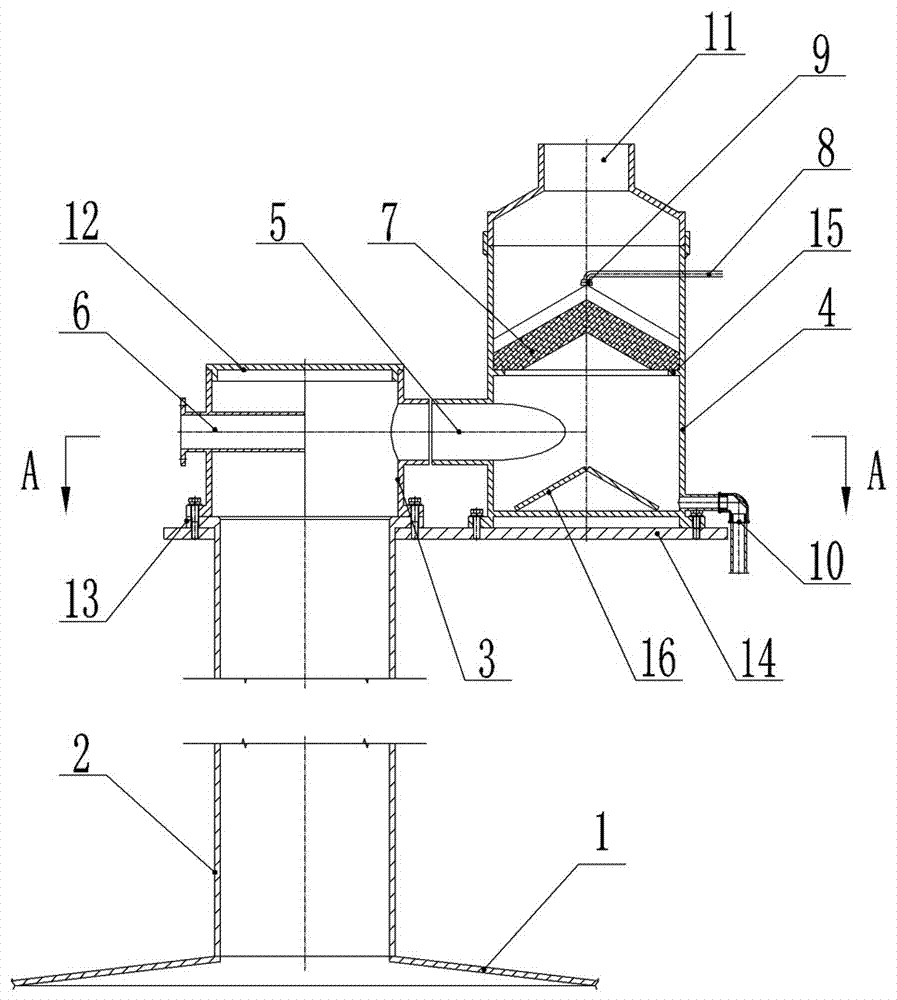

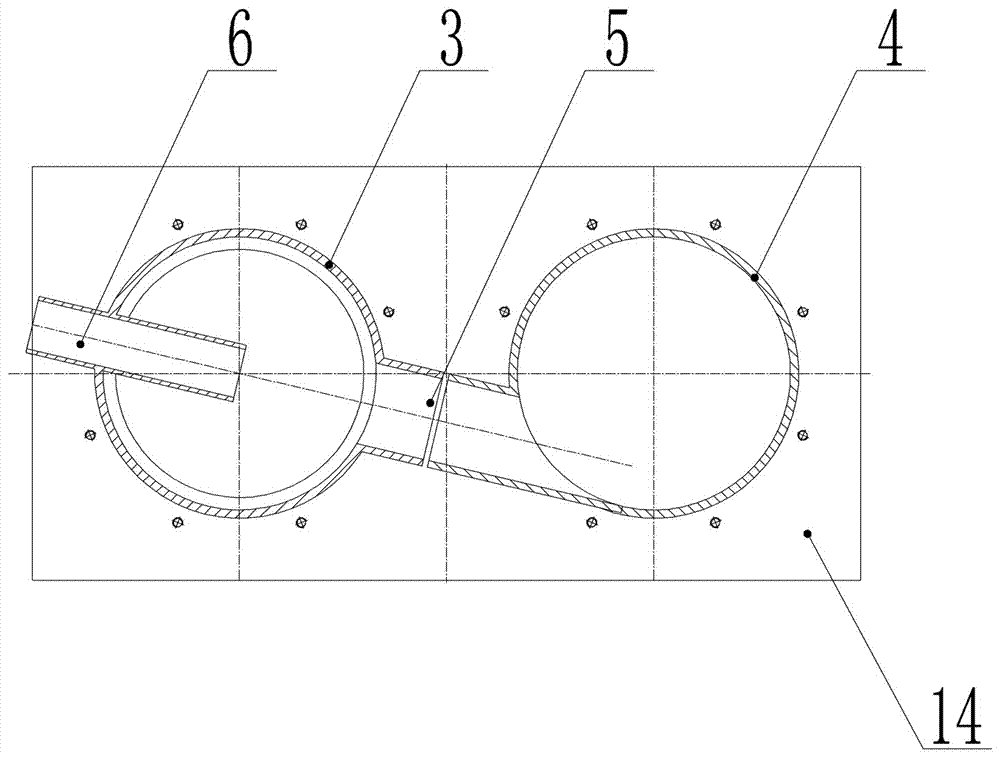

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] see figure 1 and figure 2 , a defogging assembly for steel wire surface treatment in the present invention, including a case 1 that is matched and fastened on the top of the pickling tank, a draft tube 2 that is connected to the top of the case 1, and a mist collection tower that is provided on the top of the draft tube 2 , and the separation tower arranged side by side on the side of the fog collection tower, the fog collection tower and the separation tower are connected through the air duct 5, and the side of the fog collection tower is radially provided with a mist discharge pipe 6, and the discharge The inner end of the mist pipe 6 extends to the middle of the inner chamber of the mist collecting tower and corresponds to the air duct 5, and the outer end of the mist exhaust pipe 6 is connected with a fan; the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com