Preparation method of polyimide film with ultralow dielectric constant and low dielectric loss

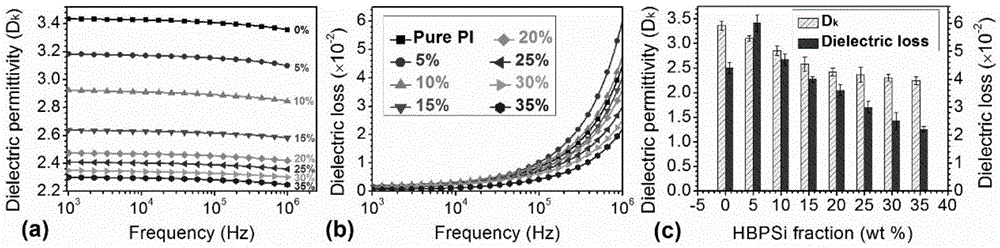

An ultra-low dielectric constant, polyimide film technology, applied in the preparation of hyperbranched polysiloxane, ultra-low dielectric constant, low dielectric loss polyimide film preparation field, can solve a wide range of limitations Application, poor mechanical properties, high research and development costs, to achieve the effect of good film transparency, low research and development costs, and increased internal free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

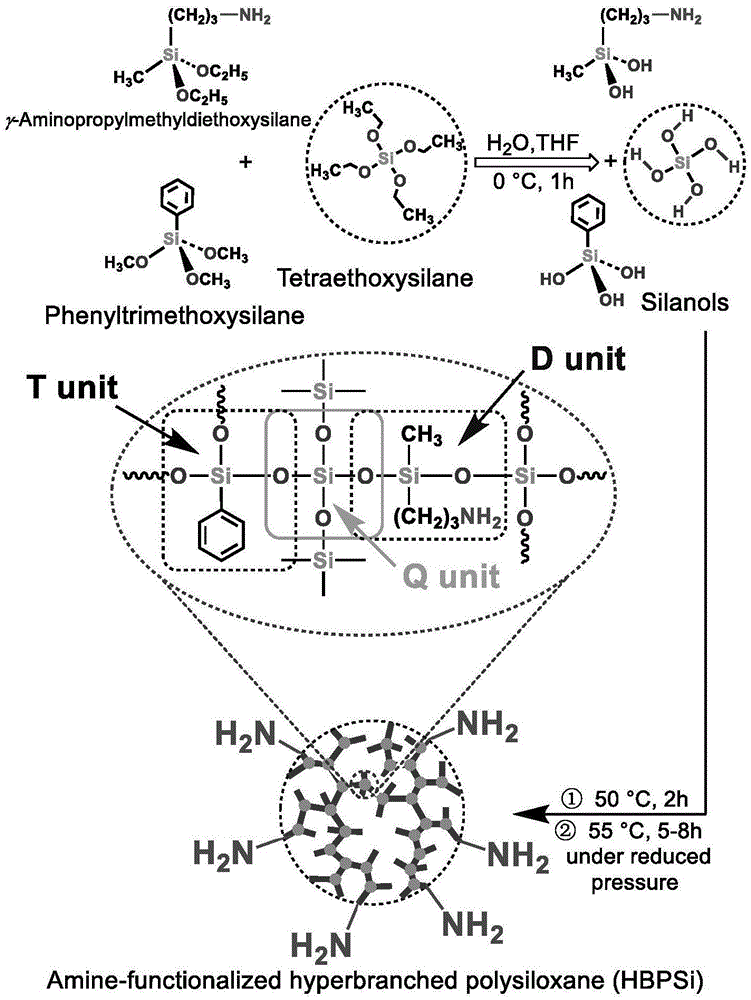

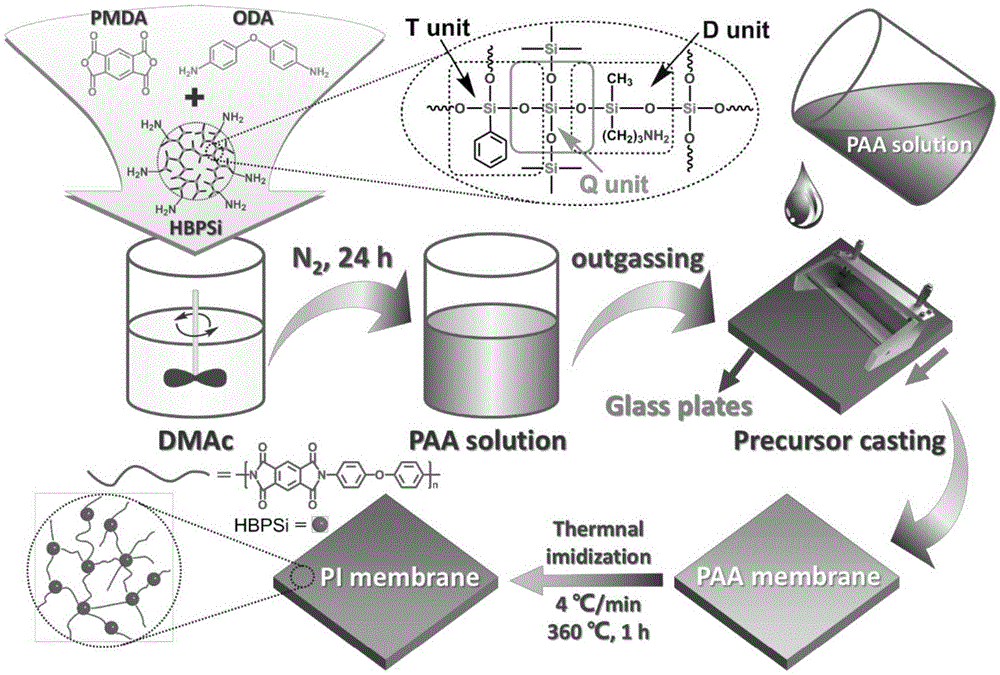

[0045] (1) Synthesis of amino-containing hyperbranched polysiloxane (HBPSi)

[0046] Add 20 g of tetrahydrofuran, 1.4476 g of SiCl in sequence to a container equipped with a magnetic stirrer 4 , 16.8964gPTMS and 1.6559gAPSM start stirring at the same time and cool down the system. When the temperature of the system dropped to 2° C., 3.68 g of distilled water was dropped into the above system within 1 h. After the end, keep the reaction conditions unchanged, continue stirring for 1 h, then raise the temperature to 40° C., and continue the reaction for 5 h. After the reaction was completed, the volatile matter was removed by rotary evaporation, the temperature was controlled at 60° C., and the pressure was 0.1 atmosphere, and the crude product E was obtained. Product E was washed twice with 50 mL of ethanol / toluene mixture (volume ratio of ethanol and toluene: 3:1) at 0°C to obtain product F. Dissolve the product F in 20 mL of chloroform and filter it with a tetrafluoro filte...

Embodiment 2

[0050] (1) Synthesis of amino-containing hyperbranched polysiloxane (HBPSi)

[0051] Add 20 g of chloroform, 1.4628 g of TEOS, 17.31 g of PTES and 1.66 g of APSE in turn into a container equipped with a magnetic stirrer, and simultaneously start stirring and cool down the system. When the temperature of the system dropped to 2° C., 3.52 g of distilled water was dropped into the above system within 1 h. After the end, keep the reaction conditions unchanged, continue stirring for 2 h, then raise the temperature to 45° C., and continue the reaction for 6 h. After the reaction was completed, the volatile matter was removed by rotary evaporation, the temperature was controlled at 60° C., and the pressure was 0.1 atmosphere, and the crude product E was obtained. Product E was washed twice with 50 mL of ethanol / toluene mixture (volume ratio of ethanol and toluene: 3:1) at 0°C to obtain product F. Dissolve the product F in 20 mL of chloroform and filter it with a tetrafluoro filter ...

Embodiment 3

[0055] (1) Synthesis of amino-containing hyperbranched polysiloxane (HBPSi)

[0056] Add 20g of chloroform, 5.7677g of TEOS, 25.8069g of MTMS and 8.4252g of UP-900M in turn into a container equipped with a magnetic stirrer and start stirring at the same time to cool down the system. When the temperature of the system dropped to 0° C., 4.59 g of distilled water was dropped into the above system within 1 h. After the end, keep the reaction conditions unchanged, continue stirring for 2 h, then raise the temperature to 40° C., and continue the reaction for 6 h. After the reaction was completed, the volatile matter was removed by rotary evaporation, the temperature was controlled at 60° C., and the pressure was 0.1 atmosphere, and the crude product E was obtained. Product E was washed twice with 50 mL of ethanol / toluene mixture at 0°C (the volume ratio of ethanol and toluene was 3:2) to obtain product F. Dissolve the product F in 20 mL of chloroform and filter it with a tetrafluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com