Model construction method for researching thermodynamic properties of repeated polyimide system by adopting system coarse graining molecular dynamics

A technology of molecular dynamics and polyimide, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of consuming a lot of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

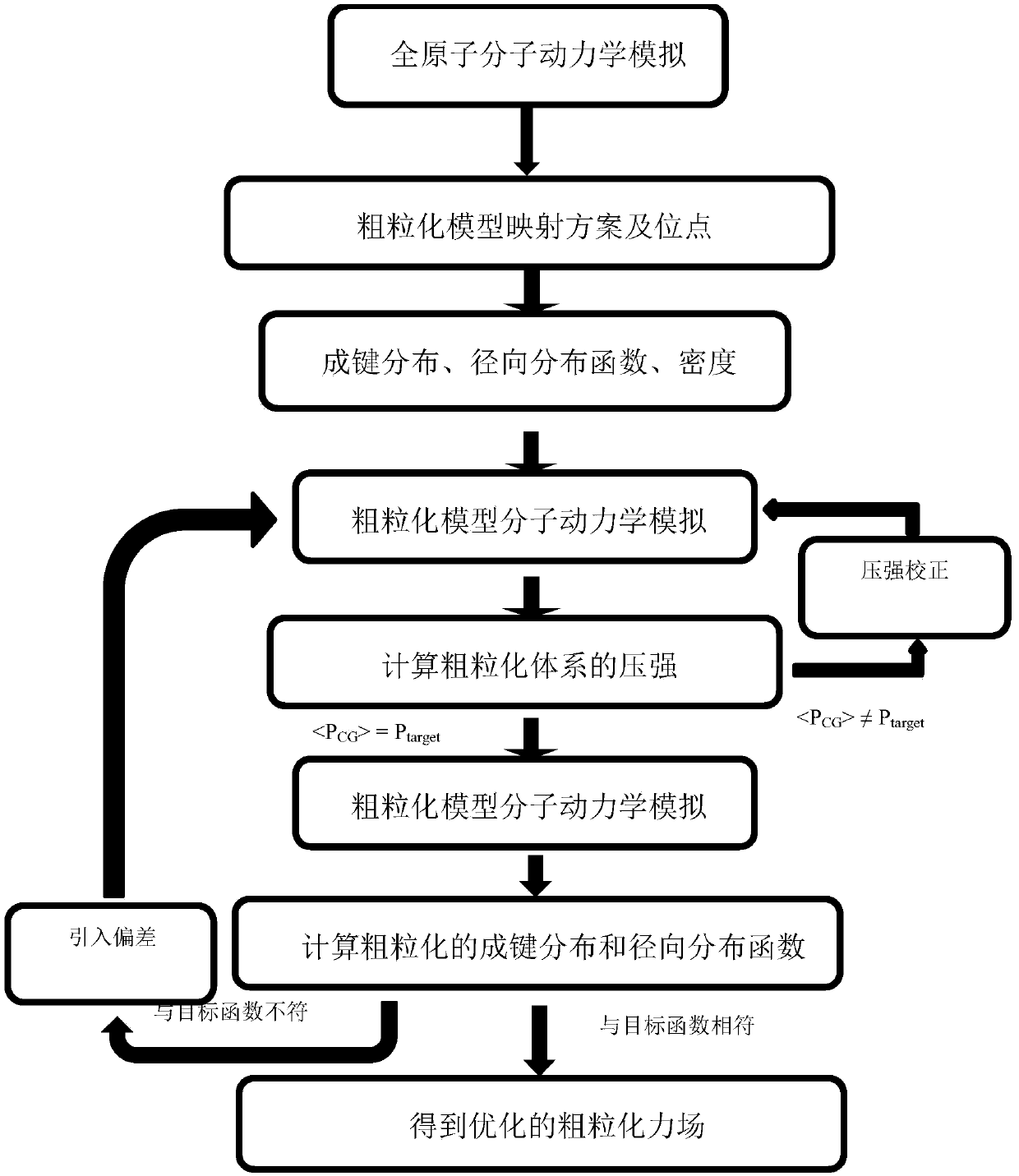

[0029] Take phenyl tetracarboxylic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) polymerized Kapton film (PMDA / ODA) as an example to illustrate the specific implementation steps of the above modeling method ( Such as figure 2 Shown):

[0030] (1) Perform all-atom molecular dynamics simulation on the PMDA / ODA melt system (PMDA / ODA molar ratio is 1:1) at 800K and 1atm to obtain the equilibrium conformation and system density at the modeling point temperature;

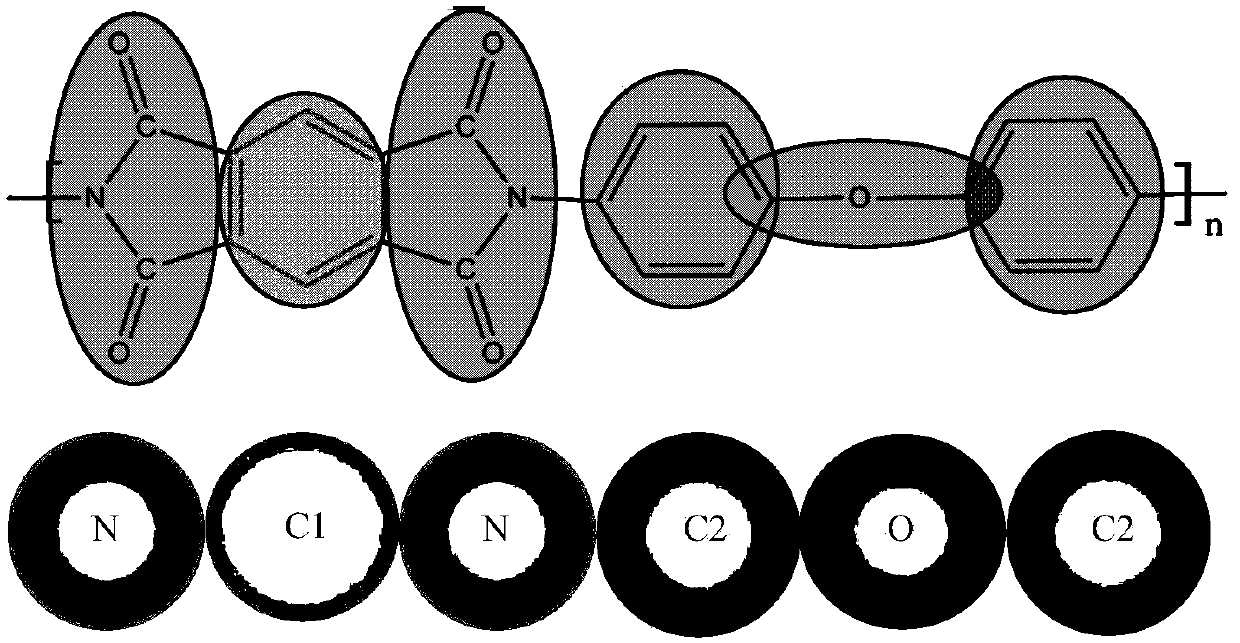

[0031] (2) Establish a mapping plan for the coarse-grained model (e.g. figure 2 (Shown), the coarse-grained site is located at the centroid of each group; (3) According to the coarse-grained scale analysis, the bond distribution function and radial distribution function RDF of the all-atom simulation (target) are obtained;

[0032] (4) The target bond distribution function and RDF obtained in step 3 are subjected to Boltzmann transformation as the initial coarse-grained force field for coarse-grained simulation;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com