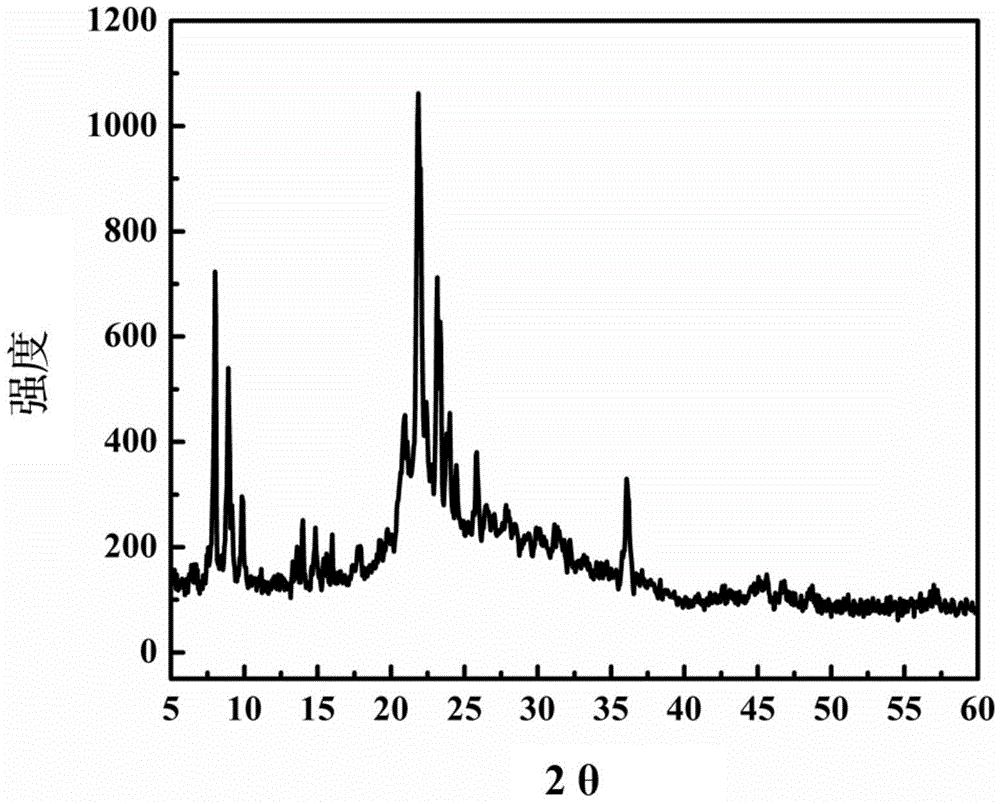

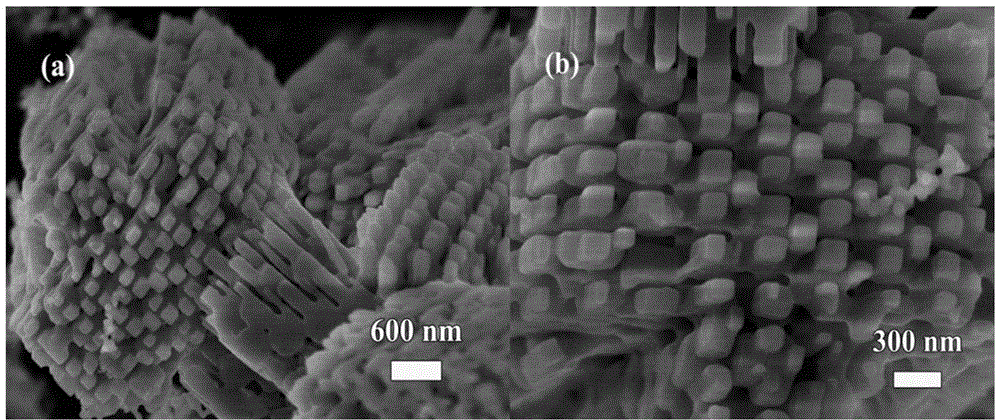

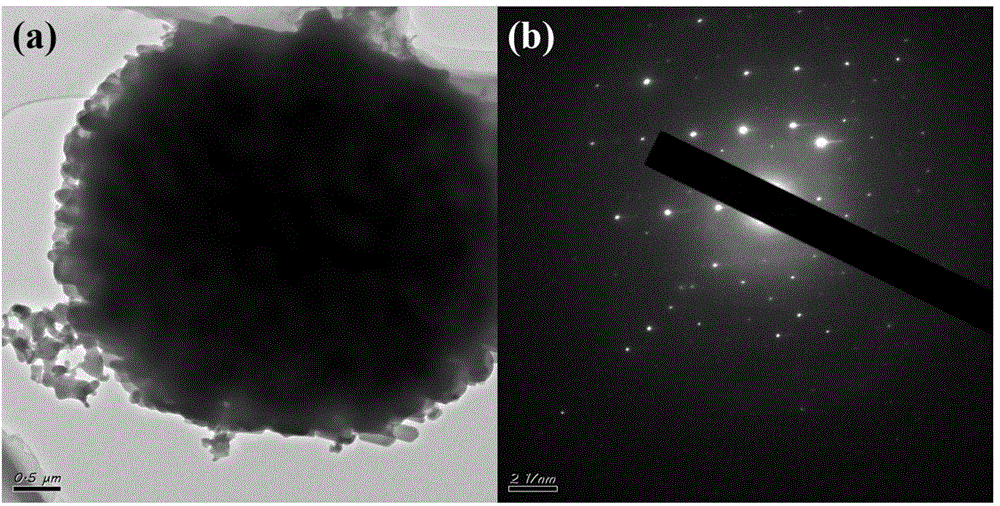

Ordered macropore-mesopore hierarchical pore titanium silicalite molecular sieve TS-1 single crystal with opal structure and synthesis method thereof

A titanium-silicon molecular sieve, TS-1 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problem of poor stability of the multi-level pore structure, and achieve the goal of improving selective catalytic performance, large pore volume, and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An ordered macroporous-mesoporous hierarchically porous titanium-silicon molecular sieve TS-1 single crystal with an opal structure, the synthesis method of which comprises the following steps:

[0034]1) Add 0.022g of titanium isopropoxide into a mixed solution formed by 0.3g of tetrapropylammonium hydroxide aqueous solution (organic templating agent, the concentration is 40wt%) and 0.9g of deionized water and stir well, then add 0.832g of orthosilicon Acetate ethyl ester, stir fully, obtain titanium silicon precursor solution, wherein the mol ratio of silicon source, titanium source, organic template agent and water (comprising the water in deionized water and tetrapropyl ammonium hydroxide aqueous solution) is 1: 0.02:0.15:15; then add 0.8g hard template (ordered macroporous-mesoporous hierarchical porous carbon material, macropore diameter is 400nm, mesopore diameter is 30nm) to obtain mixed solution I, mixed solution I is placed in 80 °C in a water bath to obtain d...

Embodiment 2

[0038] An ordered macroporous-mesoporous hierarchically porous titanium-silicon molecular sieve TS-1 single crystal with an opal structure, the synthesis method of which comprises the following steps:

[0039] 1) Add 0.0425g of tetrabutyl titanate into a mixed solution formed by 0.63g of tetrapropylammonium hydroxide aqueous solution (40wt%) and 1.42g of deionized water and stir well, then add 0.832g of ethyl orthosilicate, fully Stir evenly to obtain a titanium-silicon precursor solution, wherein the molar ratio of silicon source, titanium source, organic template agent and water (including deionized water and water in tetrapropylammonium hydroxide aqueous solution) is 1:0.031:0.3:25 ; Then add 0.8g hard template (ordered macroporous-mesoporous hierarchical carbon material, macropore diameter is 400nm, mesopore diameter is 20nm) to obtain mixed solution I, mixed solution I is placed in 80 ℃ water bath and evaporated to dryness Get dry glue.

[0040] 2) Weigh 0.8g of dry glue...

Embodiment 3

[0043] An ordered macroporous-mesoporous hierarchically porous titanium-silicon molecular sieve TS-1 single crystal with an opal structure, the synthesis method of which comprises the following steps:

[0044] 1) Add 0.0085g tetrabutyl titanate into a mixed solution formed by 0.5g tetrapropylammonium hydroxide aqueous solution (40wt%) and 0.42g deionized water and stir well, then add 0.416g ethyl orthosilicate, fully Stir evenly to obtain a titanium-silicon precursor solution, wherein the molar ratio of silicon source, titanium source, organic template agent and water (including water in deionized water and tetrapropylammonium hydroxide aqueous solution) is 1:0.0125:0.5:20 ), then add 0.4g ordered hard template (ordered macroporous-mesoporous hierarchical carbon material, macropore diameter is 400nm, mesopore diameter is 20nm) to obtain mixed solution I, mixed solution I is placed in 80 ℃ water bath evaporate to dryness to obtain dry glue;

[0045] 2) Weigh 0.3g of dry glue a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Micropore specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com