Preparation method and catalytic application of organic-inorganic hybrid ZOF-TS-1 molecular sieve

A technology of ZOF-TS-1 and molecular sieve, which is applied in molecular sieve catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., and can solve problems such as different hydrolysis rates and inhomogeneous molecular sieve precursor solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

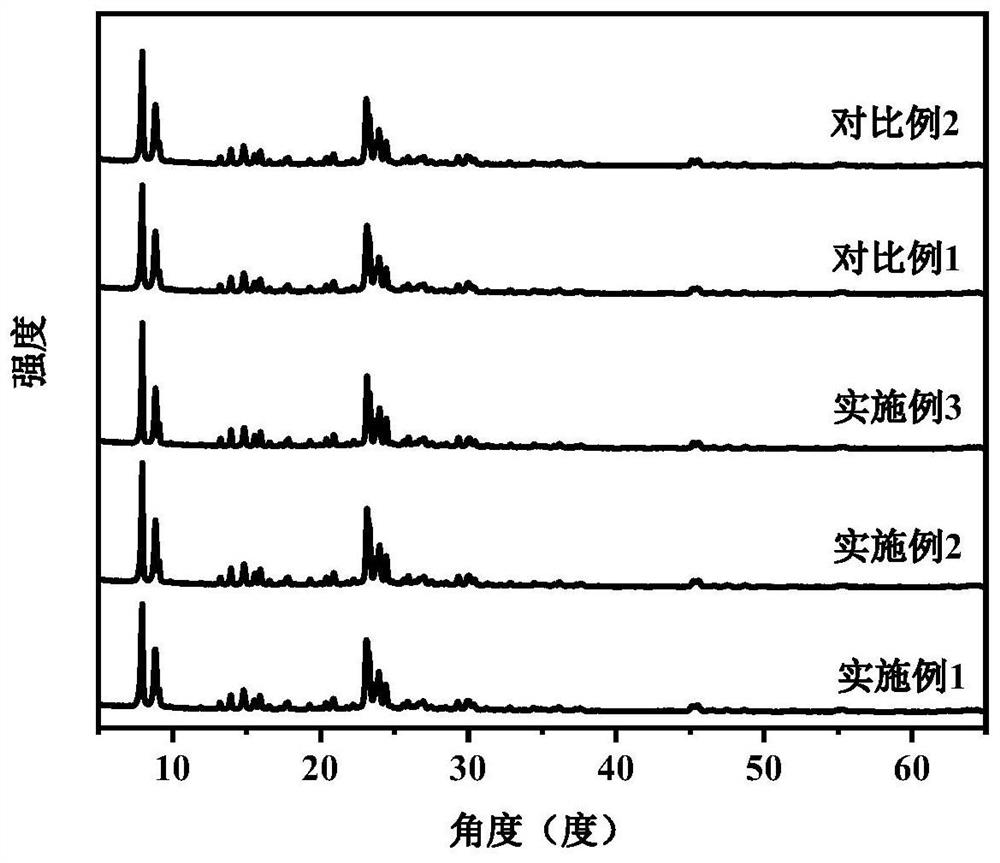

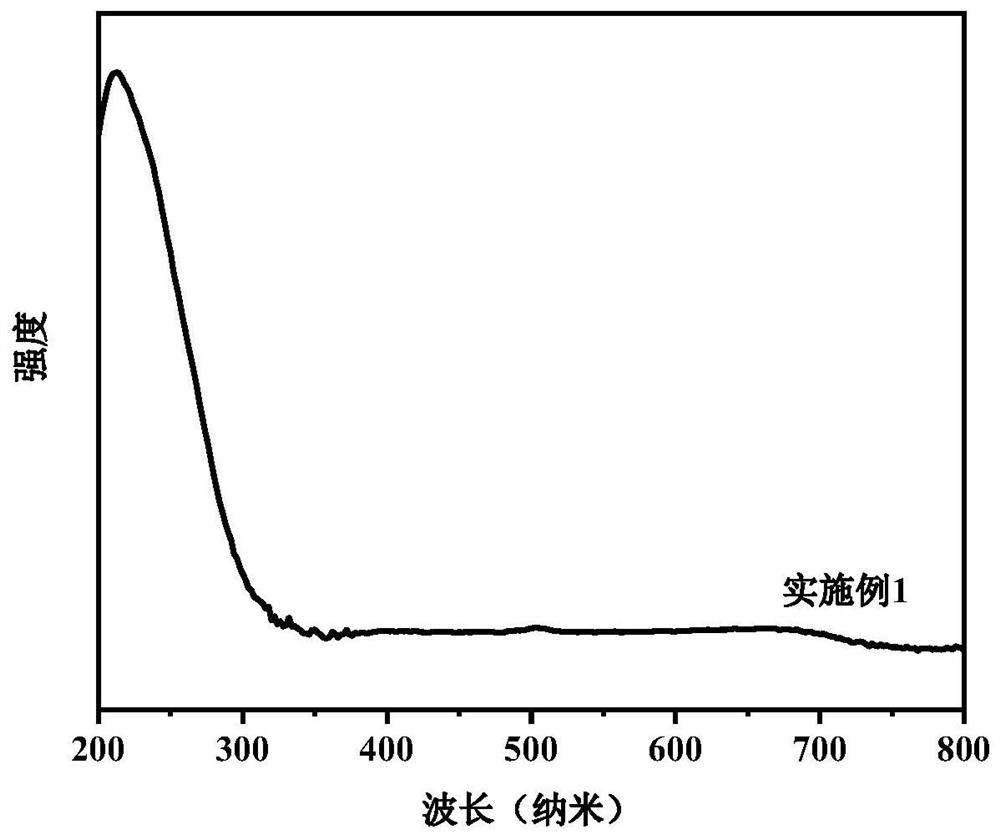

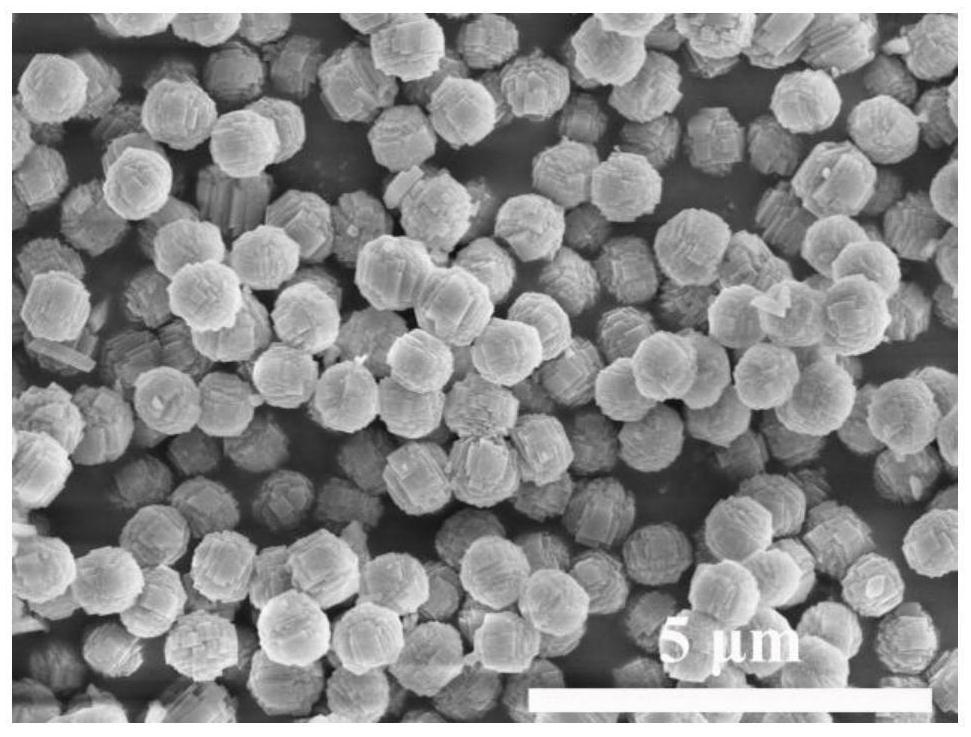

Embodiment 1

[0036] A preparation method of organic-inorganic hybrid ZOF-TS-1 molecular sieve, the specific steps are as follows:

[0037] (1) Dissolve 1.70g (0.005mol) of analytically pure bis(triethoxysilyl)methane (BTESM) in 5.08g of tetrapropylammonium hydroxide (TPAOH) aqueous solution (TPAOH is 0.005mol, and the concentration of the aqueous solution is 1mol / L, the mass percentage is 20wt%), and stirred at room temperature for 4h until BTESM is completely hydrolyzed to obtain a clear solution;

[0038] (2) Dissolve 18.75g (0.09mol) analytically pure tetraethyl silicate (TEOS) in 45.76g tetrapropylammonium hydroxide aqueous solution (TPAOH is 0.045mol, aqueous solution concentration is 1mol / L, mass percent is 20wt%) , stirred at room temperature for 4 hours, until TEOS was completely hydrolyzed to obtain a clear and transparent solution;

[0039] (3) Mix the solutions obtained in (1) and (2) evenly, and stir at room temperature for 30 minutes;

[0040] (4) 1.70 g of analytically pur...

Embodiment 2

[0046] A preparation method of organic-inorganic hybrid ZOF-TS-1 molecular sieve, the specific steps are as follows:

[0047] (1) Dissolve 3.41g (0.01mol) of analytically pure bis(triethoxysilyl)methane (BTESM) in 10.17g of tetrapropylammonium hydroxide (TPAOH) aqueous solution (TPAOH is 0.01mol, and the concentration of the aqueous solution is 1mol / L, the mass percentage is 20wt%), and stirred at room temperature for 4h until BTESM is completely hydrolyzed to obtain a clear solution;

[0048] (2) Dissolve 16.67g (0.08mol) of analytically pure tetraethyl silicate (TEOS) in 40.67g of tetrapropylammonium hydroxide aqueous solution (TPAOH is 0.04mol, the aqueous solution concentration is 1mol / L, and the mass percentage is 20wt%) , stirred at room temperature for 4 hours, until TEOS was completely hydrolyzed to obtain a clear and transparent solution;

[0049] (3) Mix the solutions obtained in (1) and (2) evenly, and stir at room temperature for 30 minutes;

[0050] (4) 1.70 g ...

Embodiment 3

[0056] A preparation method of organic-inorganic hybrid ZOF-TS-1 molecular sieve, the specific steps are as follows:

[0057] (1) Dissolve 8.51g (0.025mol) of analytically pure bis(triethoxysilyl)methane (BTESM) in 25.42g of tetrapropylammonium hydroxide (TPAOH) aqueous solution (TPAOH is 0.025mol, and the concentration of the aqueous solution is 1mol / L, the mass percentage is 20wt%), and stirred at room temperature for 4h until BTESM is completely hydrolyzed to obtain a clear solution;

[0058] (2) 10.42g (0.05mol) analytically pure tetraethyl silicate (TEOS) was dissolved in 25.42g tetrapropylammonium hydroxide aqueous solution (TPAOH is 0.025mol, aqueous solution concentration is 1mol / L, mass percent is 20wt%) , stirred at room temperature for 4 hours, until TEOS was completely hydrolyzed to obtain a clear and transparent solution;

[0059] (3) Mix the solutions obtained in (1) and (2) evenly, and stir at room temperature for 30 minutes;

[0060] (4) 1.70 g (0.005 mol) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com