A kind of synthetic method of hierarchical pore nano titanium silicon molecular sieve/alumina composite material

A technology of silicon molecular sieve and synthesis method, which is applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of limiting the transmission and diffusion of large-sized guest molecules, catalyst deactivation, and single channels, etc., to achieve Effects of improving flow diffusion performance, improving diffusion performance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

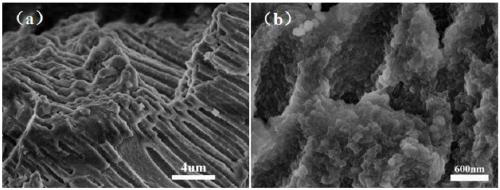

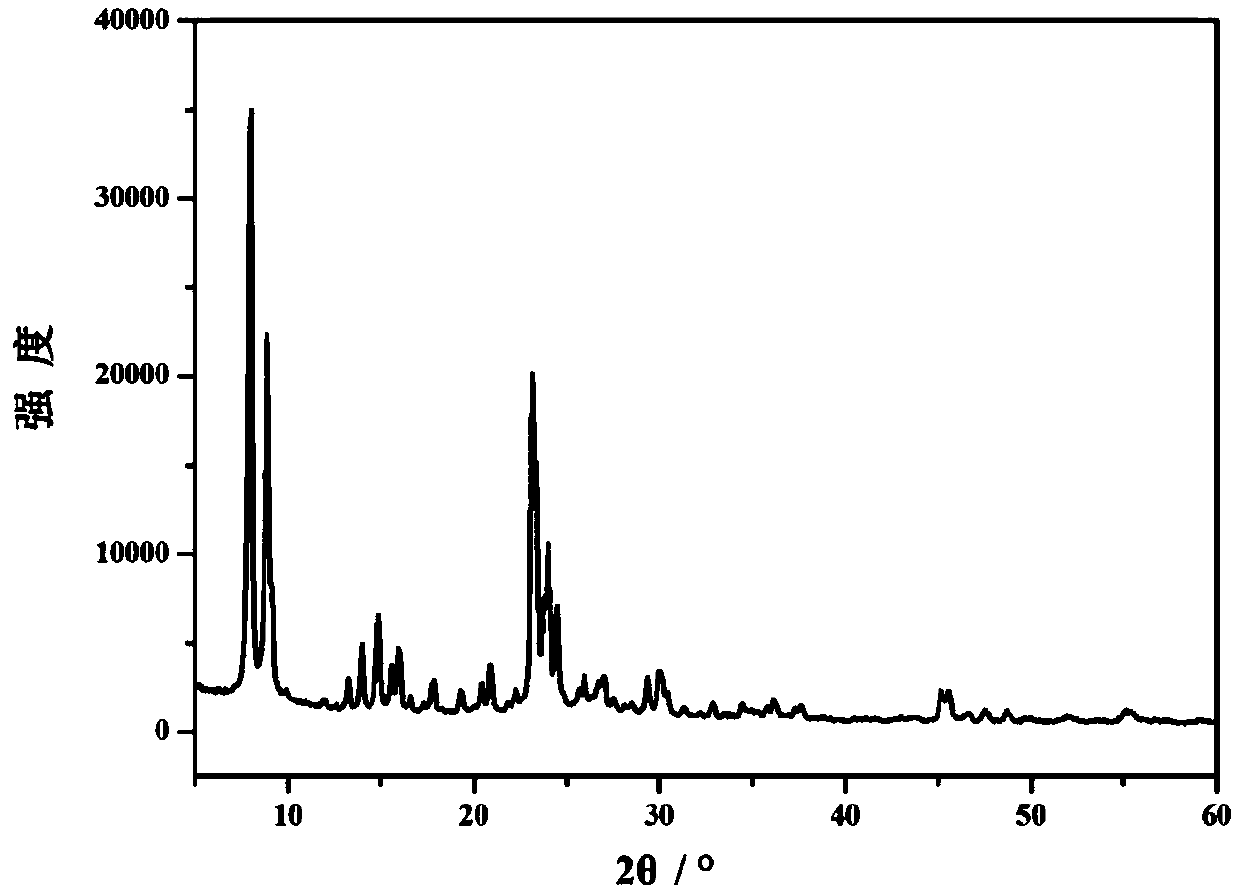

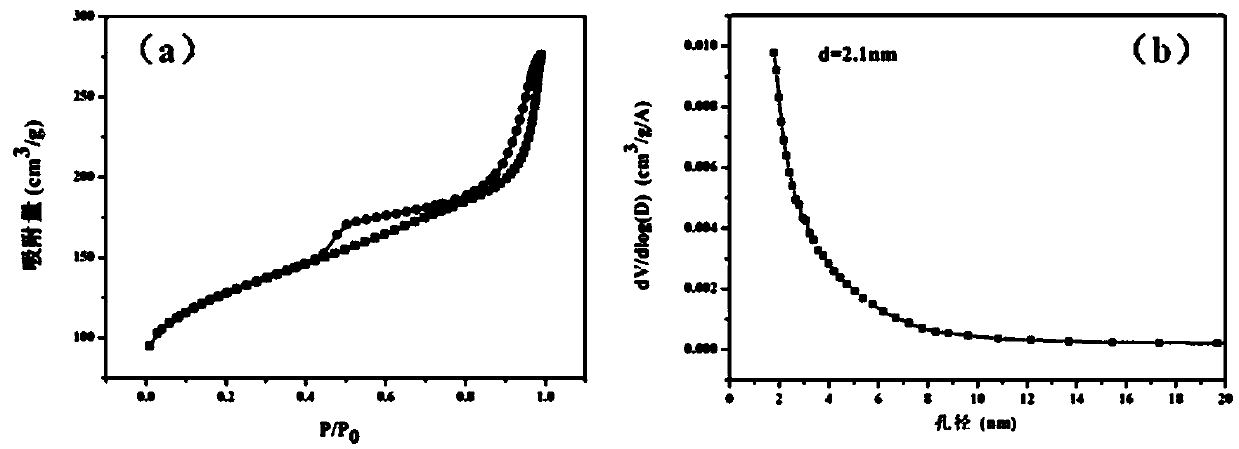

[0036] A graded hole nano titanium silicon molecular sieve / alumina composite material, the preparation method of which comprises the following steps:

[0037] Add 12.24g of tetrapropylammonium hydroxide solution with a mass fraction of 99.99% to 18.5g of tetrapropylammonium hydroxide solution with a mass fraction of 99.99%, and mix and stir for 3 hours (25°C) to obtain a mixed solution I; % tetrabutyl titanate was dispersed in 3.3g of isopropanol and mixed and stirred for 1 hour (25°C) to obtain mixed solution II; the obtained mixed solution II was added dropwise to mixed solution I and stirred for 12h (25°C), then added 23.82g deionized water to obtain the precursor solution of nano-titanium silicon molecular sieve; transfer the obtained precursor solution to a 100ml high-pressure reactor, carry out crystallization treatment at 80°C for 24 hours, wash the obtained product with water and suction filter, and then transfer to Dry in a drying oven at 60°C for 24 hours, then roast...

Embodiment 2

[0040] A graded hole nano titanium silicon molecular sieve / alumina composite material, the preparation method of which comprises the following steps:

[0041] Add 12.24g of tetrapropylammonium hydroxide solution with a mass fraction of 99.99% to 15.3g of tetrapropylammonium hydroxide solution with a mass fraction of 99.99%, and mix and stir for 3 hours (25° C.) to obtain a mixed solution I; % tetrabutyl titanate was dispersed in 2.72g isopropanol and mixed and stirred for 1 hour (25°C) to obtain mixed solution II; the obtained mixed solution II was added dropwise to mixed solution I and stirred for 12h (25°C), then 23.82g of deionized water to obtain the precursor solution of nano-titanium silicon molecular sieve; transfer the obtained precursor solution to a 100ml high-pressure reactor, carry out crystallization treatment at 100°C for 24 hours, wash the obtained product with water, and then transfer it to Dry in a drying oven at 60°C for 24 hours, and then roast at 550°C for ...

Embodiment 3

[0044] A graded hole nano titanium silicon molecular sieve / alumina composite material, the preparation method of which comprises the following steps:

[0045] Add 12.24g of tetrapropylammonium hydroxide solution with a mass fraction of 99.99% to 23.5g of tetrapropylammonium hydroxide solution with a mass fraction of 99.99%, and mix and stir for 3 hours (25°C) to obtain a mixed solution I; % tetrabutyl titanate was dispersed in 2.5g isopropanol and mixed and stirred for 1 hour (25°C) to obtain mixed solution II; the obtained mixed solution II was added dropwise to mixed solution I, stirred for 12h (25°C), and then added 23.82g of deionized water to obtain the precursor solution of nano-titanium silicon molecular sieve; transfer the obtained precursor solution to a 100ml high-pressure reactor, carry out crystallization treatment at 120°C for 24 hours, wash the obtained product with water and suction filter, and then transfer to Dry in a drying oven at 60°C for 24 hours, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com