Integrated redox flow battery stack

A liquid flow battery and liquid flow technology, applied in the field of electric energy storage, can solve the problems of poor electrolyte transmission, bulky volume and weight, and low energy efficiency, so as to reduce the phenomenon of positive and negative electrolyte internal leakage and reduce positive and negative electrolyte leakage. The effect of internal leakage of electrolyte and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and embodiment, and embodiment does not constitute limitation of the present invention:

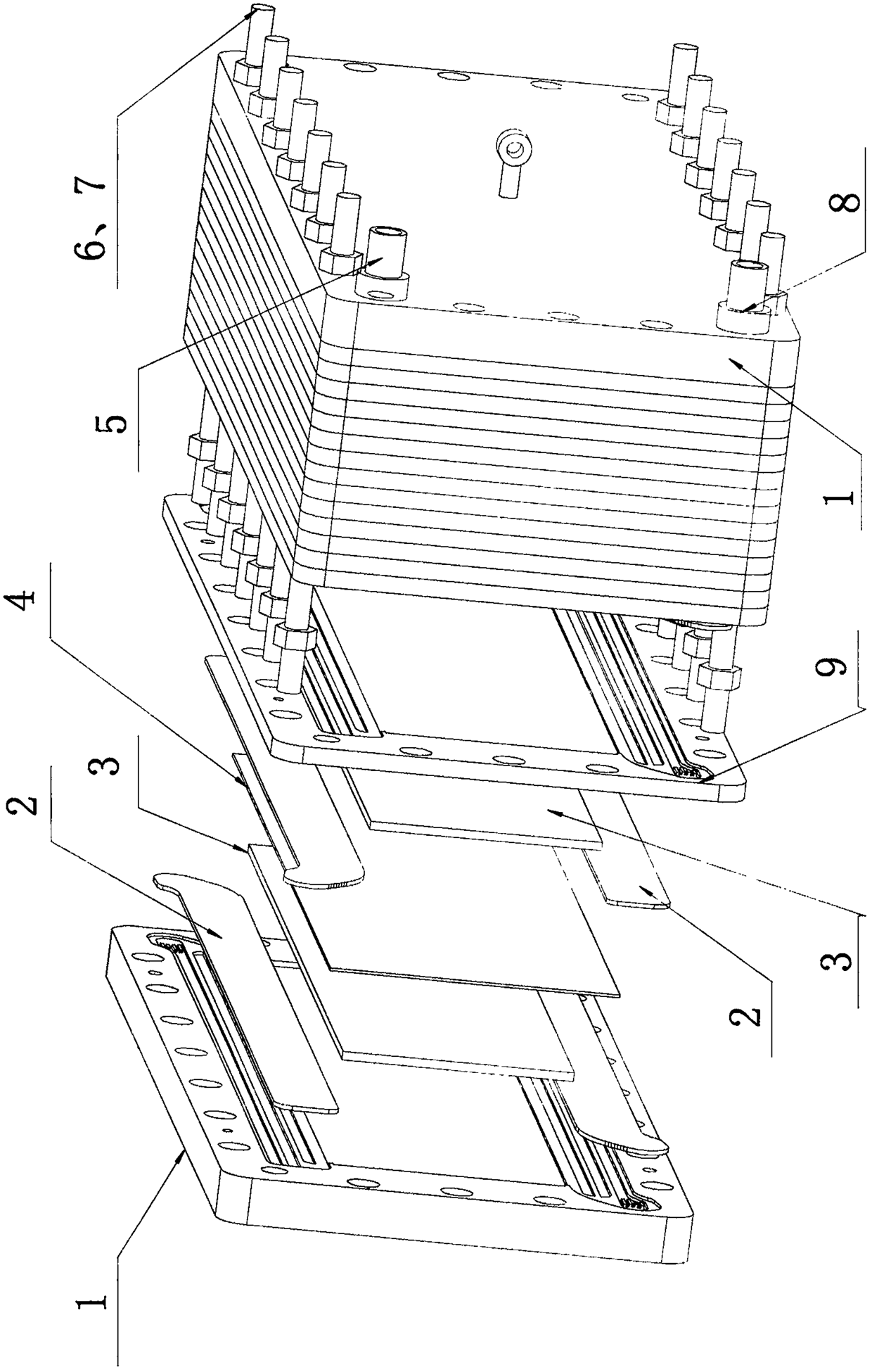

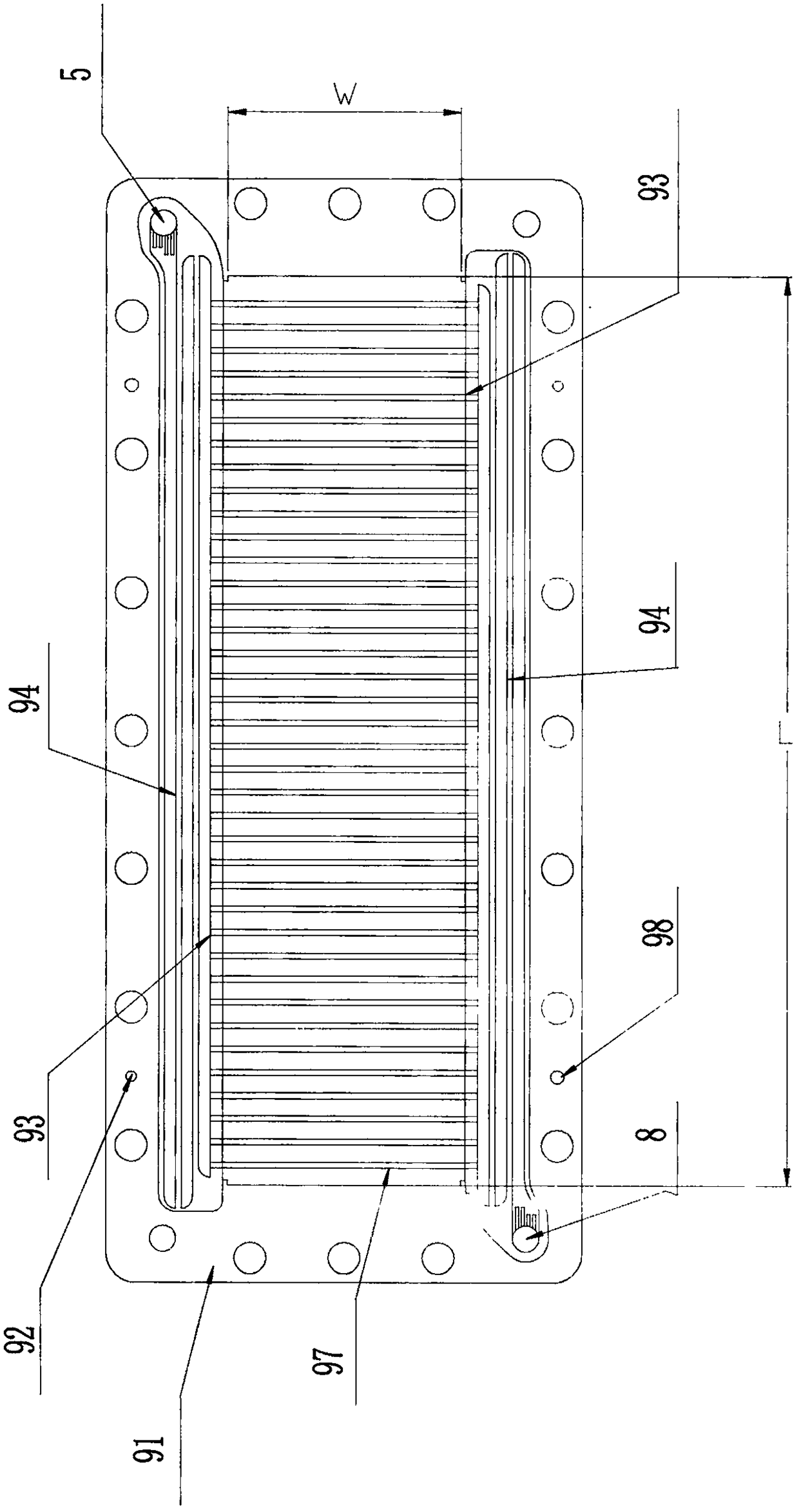

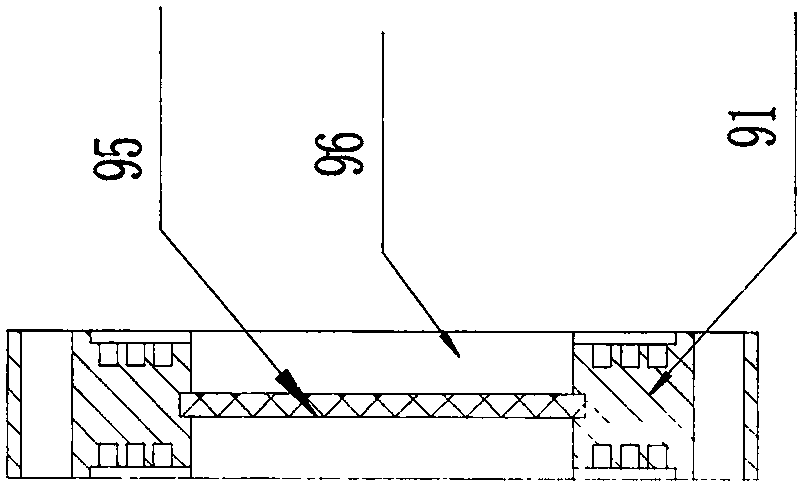

[0034] As shown in the figure, the integrated redox flow battery stack is mainly composed of an integrated liquid flow end frame plate 1, a cover plate 2, an electrode 3, a perfluorinated ion exchange membrane 4, a liquid outlet 5, bolts, nuts 6, 7. It is composed of a liquid inlet 8 and an integrated liquid flow frame plate 9. The integrated liquid flow end frame plate 1 is mainly composed of a liquid flow end frame plate 11, a conductive column 12, a collector plate 13, a conductive plastic plate 95, a liquid outlet 5, a liquid inlet 8, a positioning hole 92, and a positioning pin 98. The integrated liquid flow frame plate 9 is mainly composed of a liquid flow frame plate 91 , a positioning hole 92 , a conductive plastic plate 95 , a liquid outlet 5 and a liquid inlet 8 . The liquid fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com