Design method for determining formula of super early strength cement-based material

An early-strength cement and design method technology, applied in the field of building materials, can solve the problems of difficulty in controlling and lack of reasonable dosage of admixtures, and achieve the effects of optimized design, improved performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A formula design method for super early strength cement-based materials, comprising the steps of:

[0053] S1: Determine the mass of each solid component in the matrix of super early strength cement-based materials per cubic meter according to the close packing theory, and the results are shown in Table 1:

[0054]Table 1 Super early strength cement-based material matrix mix ratio (kg / m 3 )

[0055] composition

cement

mineral admixture

Aggregate (0~0.6mm)

Aggregate (0.6~3.35mm)

quality

900

200

600

400

[0056] S2: Determine the water-binder ratio of the super-early-strength cement-based material to be 0.2.

[0057] S3: According to the compatibility between the matrix and the superplasticizer, the mass dosage of the polycarboxylate high-efficiency superplasticizer is determined to be 1.6% of the mass of the gel material; in this embodiment, the gel material is cement and mineral admixtures.

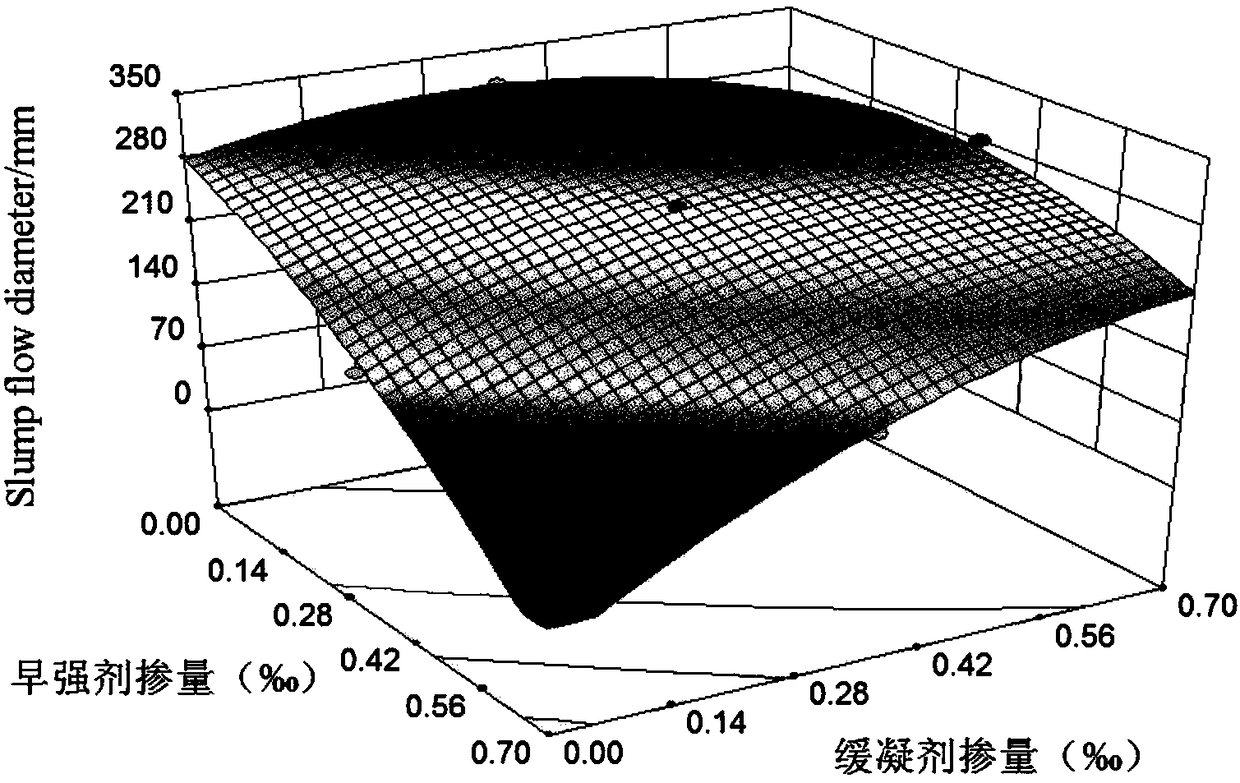

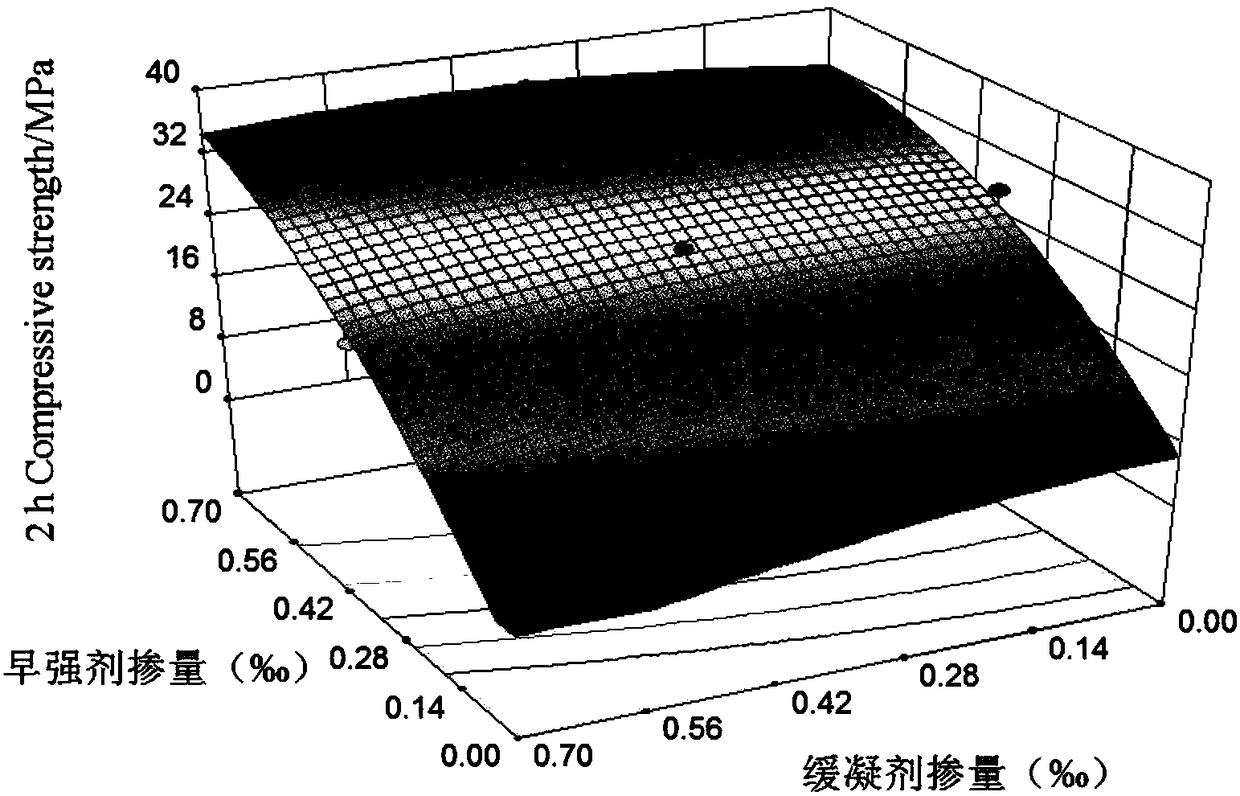

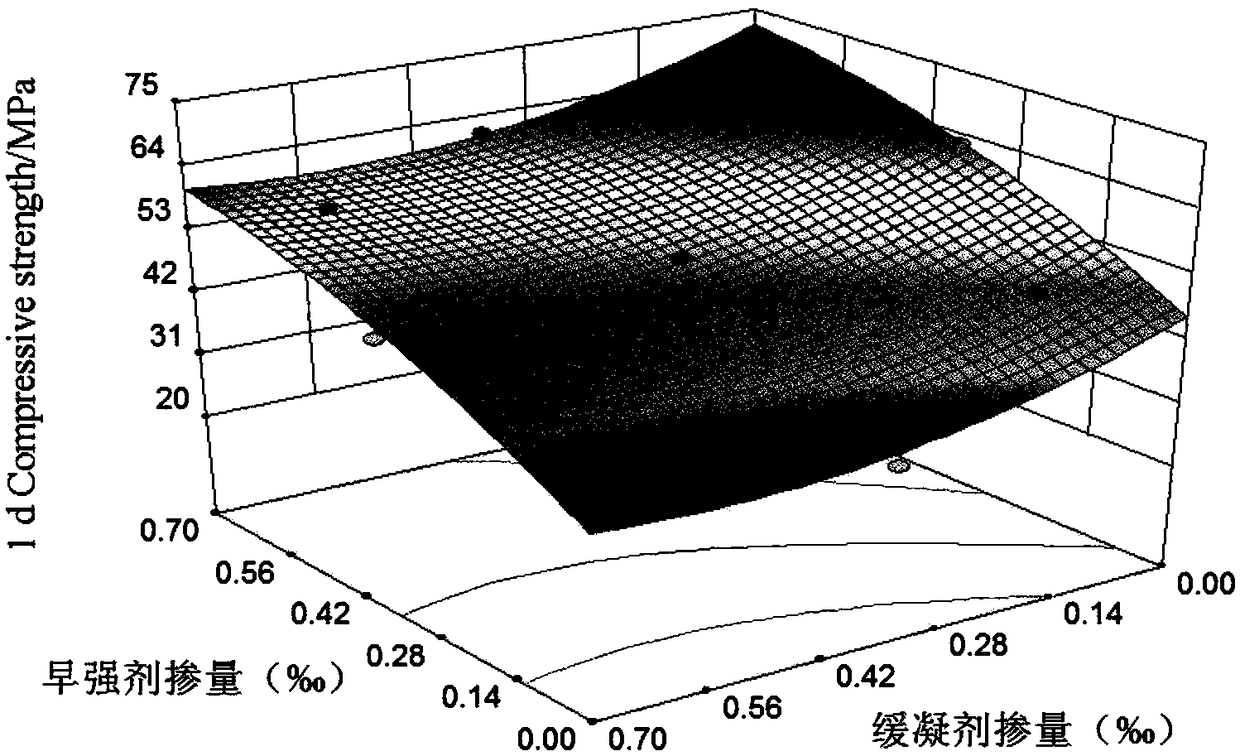

[0058] S4: Response surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com