PG (performance graded) compound asphalt modifier and modified asphalt prepared from same

A technology of compound asphalt and modified asphalt, applied in building components, building insulation materials, construction and other directions, can solve problems such as the increase of system viscosity, achieve the effect of improving comprehensive performance, reducing system viscosity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1, preparation of PG graded composite asphalt modifier and PG88-28 modified asphalt

[0040] 1. Preparation of PG graded composite asphalt modifier

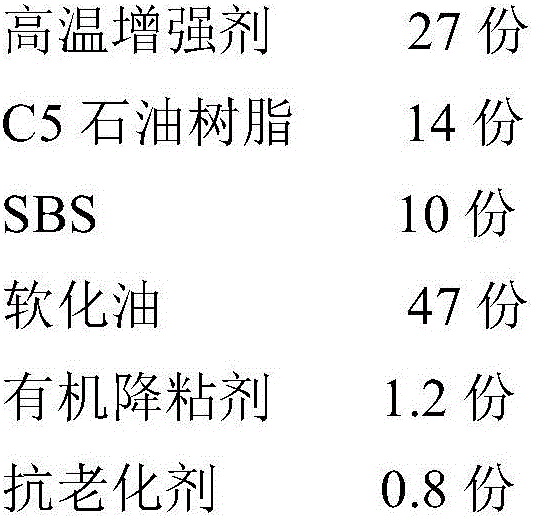

[0041] In parts by weight, the formula of the PG graded composite asphalt modifier in this embodiment is as follows:

[0042]

[0043] The preparation method is as follows: according to the above formula, mix the components except softening oil, then add softening oil to soften, and extrude through a twin-screw extruder to obtain the PG graded composite asphalt modifier.

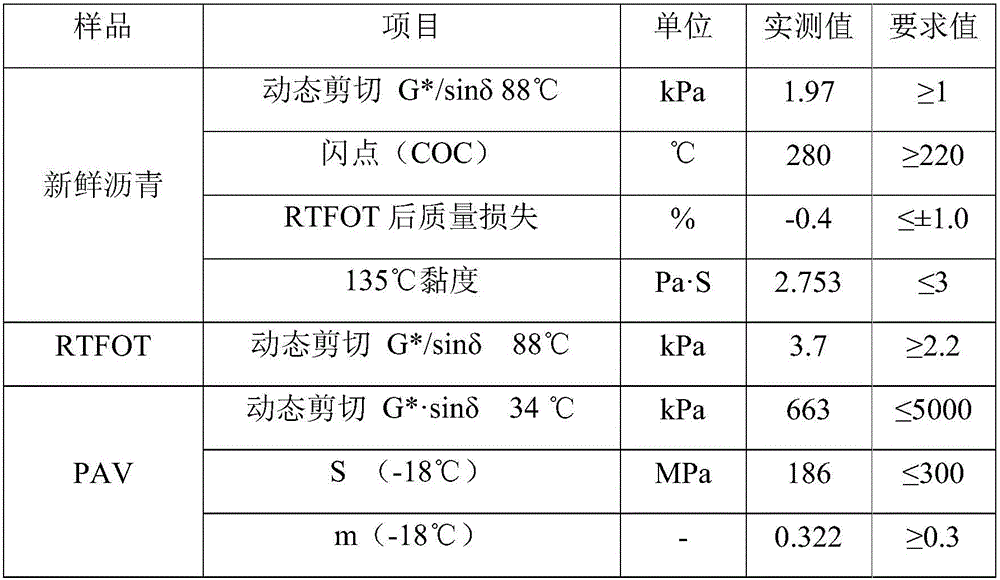

[0044] 2. Prepare PG88-28 modified asphalt by using the above-mentioned PG graded composite asphalt modifier

[0045]Prepare PG88-28 modified asphalt according to the following steps:

[0046] Raise the temperature of No. 70 base asphalt to 150°C, and evenly add the PG graded composite asphalt modifier prepared above, wherein the ratio of PG graded composite asphalt modifier: base asphalt is 1:1.8, start stirring and raise the temperature to...

Embodiment 2

[0052] Example 2, preparation of PG graded composite asphalt modifier and PG88-28 modified asphalt

[0053] 1. Preparation of PG graded composite asphalt modifier

[0054] In parts by weight, the formula of the PG graded composite asphalt modifier in this embodiment is as follows:

[0055]

[0056] The preparation method is as follows: according to the above formula, mix the components except softening oil, then add softening oil to soften, and extrude through a twin-screw extruder to obtain the PG graded composite asphalt modifier.

[0057] 2. Prepare PG88-28 modified asphalt by using the above-mentioned PG graded composite asphalt modifier

[0058] Prepare PG88-28 modified asphalt according to the following steps:

[0059] Raise the temperature of No. 70 base asphalt to 150°C, and evenly add the PG graded composite asphalt modifier prepared above, wherein the ratio of PG graded composite asphalt modifier: base asphalt is 1:1.8, start stirring and raise the temperature t...

Embodiment 3

[0065] Example 3, preparation of PG graded composite asphalt modifier and PG88-28 modified asphalt

[0066] 1. Preparation of PG graded composite asphalt modifier

[0067] In parts by weight, the formula of the PG graded composite asphalt modifier in this embodiment is as follows:

[0068]

[0069] The preparation method is as follows: according to the above formula, mix the components except softening oil, then add softening oil to soften, and extrude through a twin-screw extruder to obtain the PG graded composite asphalt modifier.

[0070] 2. Prepare PG88-28 modified asphalt by using the above-mentioned PG graded composite asphalt modifier

[0071] Prepare PG88-28 modified asphalt according to the following steps:

[0072] Raise the temperature of No. 50 base asphalt to 150°C, and evenly add the composite modifier, wherein the ratio of composite modifier: base asphalt is 1:2.2, start stirring and raise the temperature to 185°C, and stir at 200 rpm for 4 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com