Inorganic phenolic aldehyde composite thermal mortar

A composite thermal insulation mortar and phenolic technology, which is applied in the field of building energy-saving thermal insulation, can solve the problems of phenolic foam thermal insulation system such as brittleness, high thermal conductivity, and wall corrosion, and achieve the effects of reducing thermal conductivity, improving bonding performance, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

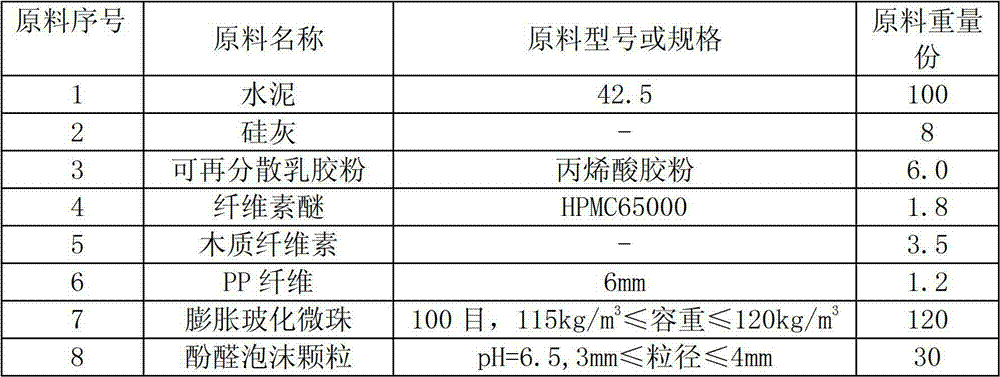

[0041] The raw material composition and parts by weight of the inorganic phenolic composite thermal insulation mortar of the present embodiment are as shown in Table 3:

[0042] table 3

[0043] Raw material serial number

[0044] Using cement and silica fume as the gelling material, the phenolic foam particles and Expanded vitrified microbeads are lightweight aggregates for heat preservation, adding acrylic rubber powder, cellulose ether for thickening and water retention (HPMC60000, that is, hydroxypropyl methylcellulose with a viscosity of 60000mPa.s), lignocellulose, The PP fibers used to improve the strength are mixed evenly and obtained.

Embodiment 2

[0046] The raw material composition and parts by weight of the inorganic phenolic composite thermal insulation mortar of the present embodiment are as shown in Table 4:

[0047] Table 4

[0048] Raw material serial number

[0049] 4

[0050] Use cement and silica fume as the gelling material, neutralize it with an alkaline regulator (1.0mol / L sodium hydroxide aqueous solution) to a pH value of 7.5, and then seal the surface with a waterproof emulsion (styrene-acrylate emulsion) The treated phenolic foam particles and expanded vitrified microbeads are lightweight aggregates for heat preservation. Add polyvinyl alcohol powder, cellulose ether for thickening and water retention, lignocellulose, and PP fibers for strength improvement, and mix evenly. Vested.

Embodiment 3

[0052] The raw material composition and parts by weight of the inorganic phenolic composite thermal insulation mortar of the present embodiment are as shown in Table 5:

[0053] table 5

[0054] Raw material serial number

[0055]Using cement and silica fume as the cementitious material, the phenolic foam particles and the Expanded vitrified microbeads are lightweight aggregates for heat preservation, adding polyvinyl alcohol powder, cellulose ether for thickening and water retention, lignocellulose, and PP fibers for improving strength, and mix evenly to obtain it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com