Flame-retardant polyurethane spraying rigid foam plastic

A technology of rigid foam and polyurethane, applied in the field of rigid foam, can solve the problems of increasing the flame retardant grade of sprayed rigid foam, and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

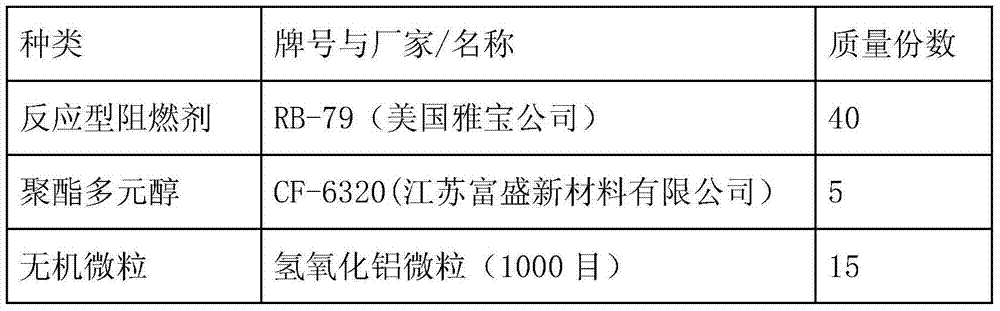

[0041] Polyol component:

[0042]

[0043]

[0044] Isocyanate component: polymethylene polyphenyl polyisocyanate PM-200 (Wanhua Chemical Group Co., Ltd.);

[0045] The volume ratio of isocyanate component to polyol component is 1:1;

[0046] Equipment: H25 spraying machine (Graco, USA).

[0047] Production steps:

[0048] (1) Insert the two-component lifting pumps of the spraying machine into the corresponding raw material barrels, turn on the power and air compressor and other preparations;

[0049] (2) Set the heating temperature of spraying machine raw materials and pipelines to 50°C;

[0050] (3) Use a spray gun to spray the raw material on the substrate, and spray more than 5 layers to complete the foam with a thickness of 8cm;

[0051] The color of the prepared foam is uniform gray, and the properties are as follows:

[0052]

[0053]

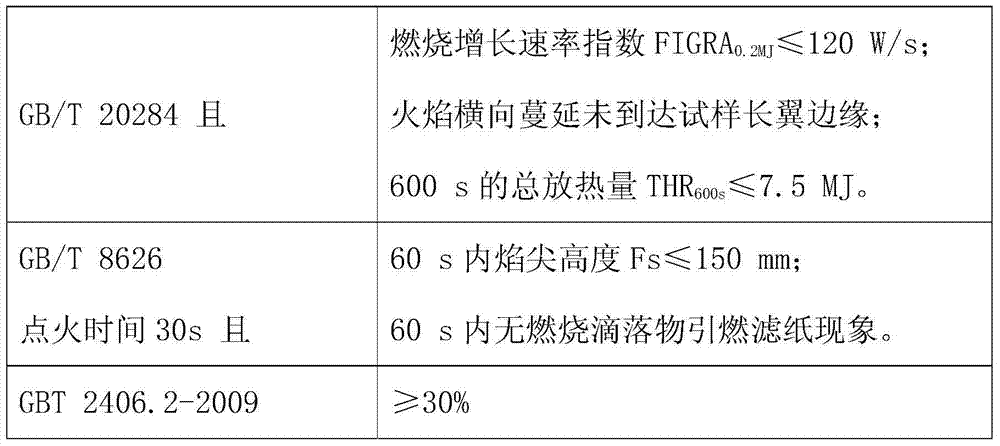

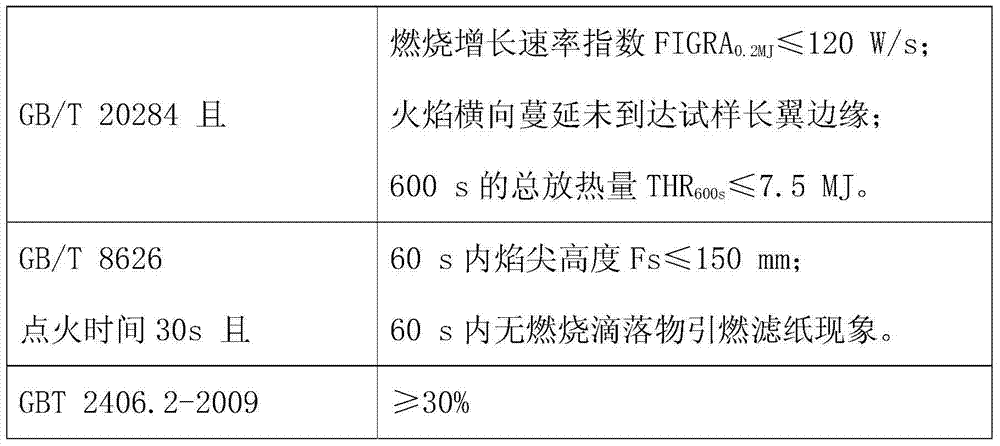

[0054] The measured flame retardant performance index meets the national standard GB8624-2012 "Classification of Combu...

Embodiment 2

[0056] Polyol component:

[0057]

[0058]

[0059] Isocyanate component: polymethylene polyphenyl polyisocyanate PM-200 (Wanhua Chemical Group Co., Ltd.) 80wt%, aluminum hydroxide particles (800 mesh) 20wt%;

[0060] Equipment: H25 spraying machine (Graco, USA);

[0061] The volume ratio of isocyanate component to polyol component is 1:1;

[0062] Production steps:

[0063] (1) Insert the two-component lifting pumps of the spraying machine into the corresponding raw material barrels, turn on the power and air compressor and other preparations;

[0064] (2) Set the heating temperature of spraying machine raw materials and pipelines to 50°C;

[0065] (3) Use a spray gun to spray the raw material on the substrate, and spray more than 5 layers to complete the foam with a thickness of 8cm;

[0066] The color of the prepared foam is uniform light yellow, and the properties are as follows:

[0067]

[0068]

[0069] The measured flame retardant performance index mee...

Embodiment 3

[0071] Polyol component:

[0072]

[0073]

[0074] Isocyanate component: polymethylene polyphenyl polyisocyanate PM-200 (Wanhua Chemical Group Co., Ltd.) 88wt%, aluminum hydroxide particles (800 mesh) 10wt%; color paste 036-2M1941 (Baomeishi Chemical Industry ( Shanghai) Co., Ltd.) 2wt%;

[0075] The volume ratio of isocyanate component to polyol component is 1:1;

[0076] Equipment: H25 spraying machine (Graco, USA)

[0077] Production steps:

[0078] (1) Insert the two-component lifting pumps of the spraying machine into the corresponding raw material barrels, turn on the power and air compressor and other preparations;

[0079] (2) Set the heating temperature of spraying machine raw materials and pipelines to 50°C;

[0080] (3) Use a spray gun to spray the raw material on the substrate, and spray more than 5 layers to complete the foam with a thickness of 8cm;

[0081] The color of the prepared foam is uniform gray, and the properties are as follows:

[0082] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com