Construction method for outer wall outer thermal insulation rock wool boards

A technology of external thermal insulation and construction methods for external walls, applied in the direction of thermal insulation, building material processing, building components, etc., can solve the problems of reducing building use area, large damage of thermal insulation layer, cracking of internal thermal insulation surface layer, etc., and achieve the design of construction steps Reasonable, high combustion performance level, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The construction method of the external wall thermal insulation rock wool board of the present invention adopts the following technological process:

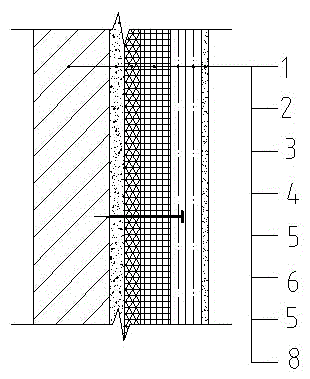

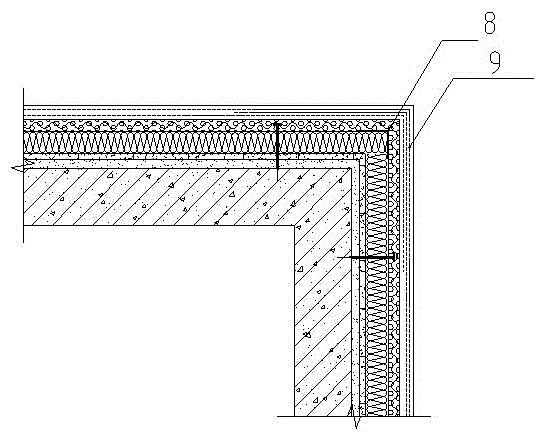

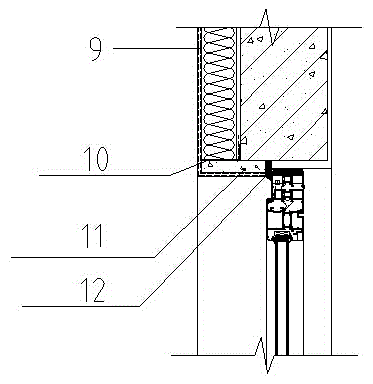

[0057] Materials and tools preparation → base wall treatment → ash layer → bonding mortar → rock wool board insulation → surface mortar composite mesh cloth → anchor bolts → surface mortar composite mesh cloth → paint layer. figure 1 It is a schematic diagram of the structure of a rock wool board double-layer glass fiber net thin plastered exterior wall according to an embodiment of the present invention. The length of the rock wool board should not be greater than 1200mm, and the width should not be greater than 600mm. It should be dry and the surface should be smooth and clean.

[0058] The construction method of the external wall thermal insulation rock wool board of the present invention is characterized in that comprising the following steps:

[0059] a. Playing the control line and hanging the reference line, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com