Polycarboxylic acid water reducing agent suitable for high-strength self-compacting concrete and preparation method of polycarboxylic acid water reducing agent

A technology of self-compacting concrete and polycarboxylic acid, which is applied in the field of concrete admixtures, can solve the problems of poor segregation resistance, insufficient dispersibility, and high price, and achieve the effect of large fluidity, good dispersibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

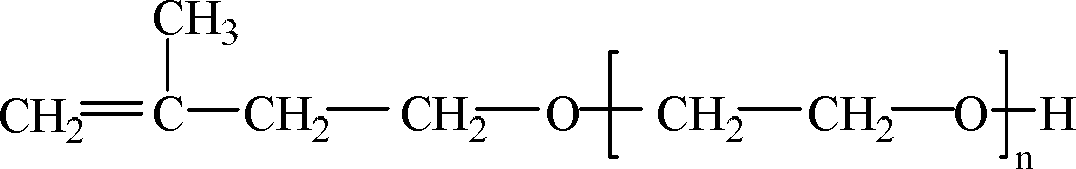

Image

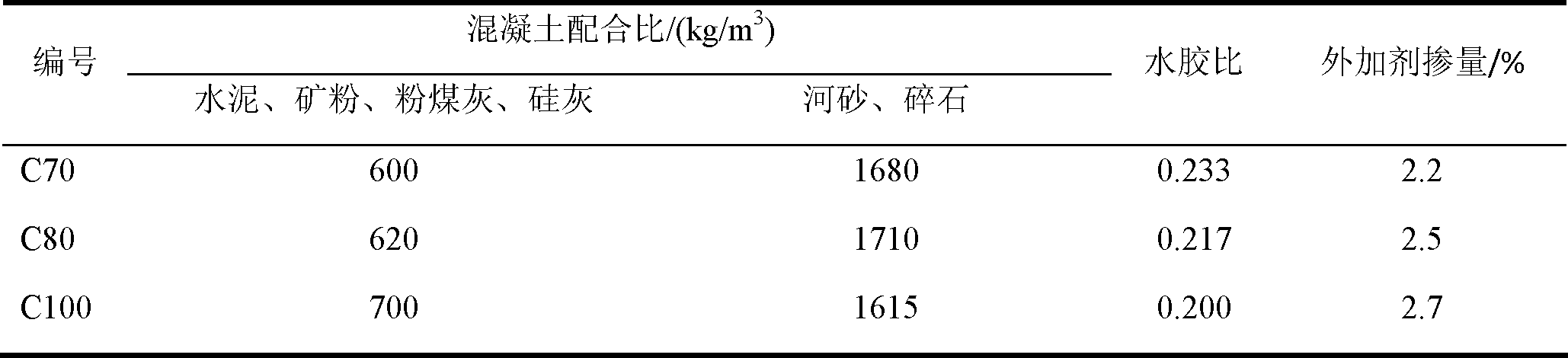

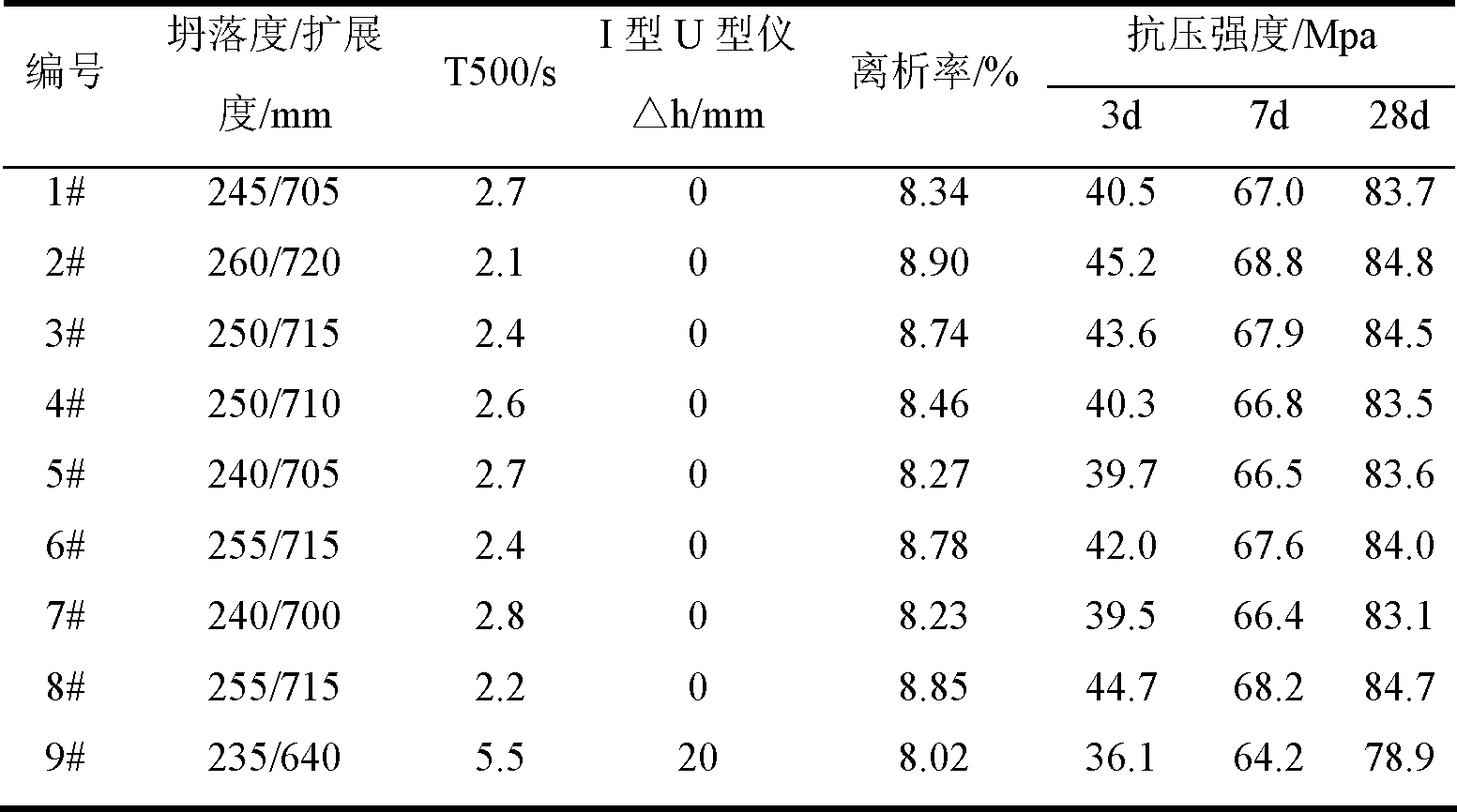

Examples

Embodiment 1

[0022] In a 500ml four-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g deionized water, 180g isopentenyl polyoxyethylene ether macromonomer (polymerization degree n=26) and 16.0g maleic anhydride , turn on nitrogen, heat in a water bath, control the temperature at about 40°C, stir while heating, after the isopentenyl polyoxyethylene ether macromonomer and maleic anhydride are dissolved, slowly raise the temperature to 60°C, add 2.0g Allyloxy hydroxypropyl sulfonate and 1.0 g of ammonium persulfate were added dropwise to 60 g of an aqueous solution containing 4.0 g of acrylic acid and 80 g of an aqueous solution containing 0.25 g of thioglycolic acid. The dropping time of the acrylic acid aqueous solution is 4 hours, and the dropping time of the thioglycolic acid aqueous solution is 4.5 hours. After the dropwise addition, continue to keep warm at 60°C for 1 hour, then cool down to 40°C, add alkali to neutralize, and add deionized water to adju...

Embodiment 2

[0024] In a 500ml four-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g deionized water, 180g isopentenyl polyoxyethylene ether macromonomer (polymerization degree n=46) and 16.0g maleic anhydride , turn on nitrogen, heat in a water bath, control the temperature at about 40°C, stir while heating, after the isopentenyl polyoxyethylene ether macromonomer and maleic anhydride are dissolved, slowly raise the temperature to 60°C, add 8.0g Allyloxy hydroxypropyl sulfonate and 1.0 g of ammonium persulfate were added dropwise to 60 g of an aqueous solution containing 4.0 g of acrylic acid and 60 g of an aqueous solution containing 0.25 g of thioglycolic acid. The dropping time of the acrylic acid aqueous solution is 4 hours, and the dropping time of the thioglycolic acid aqueous solution is 4.5 hours. After the dropwise addition, continue to keep warm at 60°C for 1 hour, then cool down to 40°C, add alkali to neutralize, and add deionized water to adju...

Embodiment 3

[0026]In a 500ml four-necked flask equipped with a thermometer, a stirrer and a dropping funnel, add 100g deionized water, 180g isopentenyl polyoxyethylene ether macromonomer (polymerization degree n=46) and 16.0g maleic anhydride , turn on nitrogen, heat in a water bath, control the temperature at about 40°C, stir while heating, after the isopentenyl polyoxyethylene ether macromonomer and maleic anhydride are dissolved, slowly raise the temperature to 60°C, add 10.0g Sodium allyloxyhydroxypropyl sulfonate and 0.6 g of ammonium persulfate were added dropwise to 60 g of an aqueous solution containing 4.0 g of acrylic acid and 60 g of an aqueous solution containing 0.1 g of thioglycolic acid, respectively. The dropping time of the acrylic acid aqueous solution is 4 hours, and the dropping time of the thioglycolic acid aqueous solution is 4.5 hours. After the dropwise addition, continue to keep warm at 60°C for 3 hours, then cool down to 40°C, add alkali to neutralize and add deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com