Method for preparing niobium sheet metal strip

A technology of metal niobium and strip, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of low grain size, unstable elongation performance, short length of niobium strip, etc., and achieve high elongation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

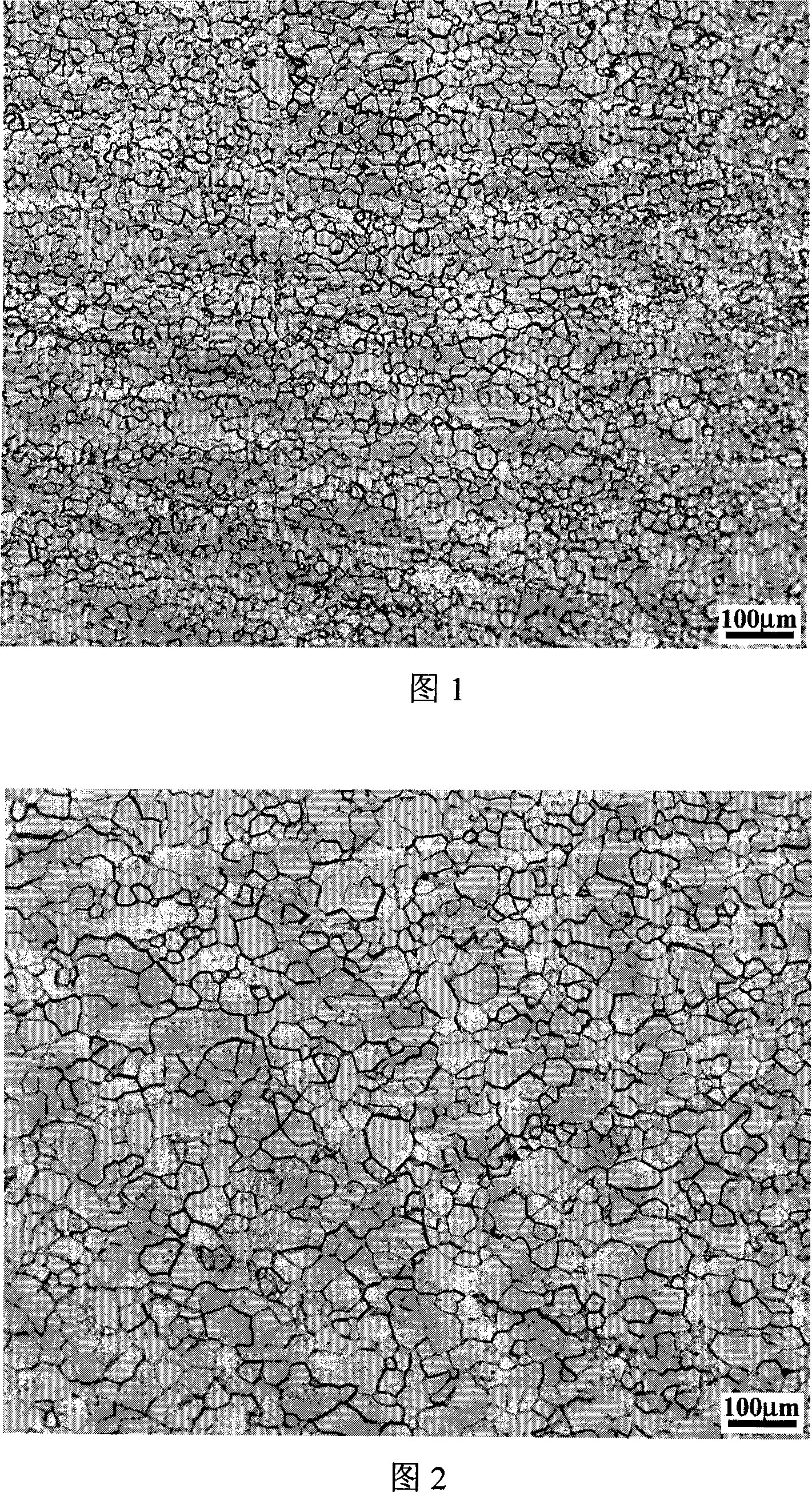

Embodiment 1

[0019] One electron beam secondary smelting ingot, heated in an electric furnace at 800°C for 80 minutes, upsetting ratio 35% to a length of 130mm, and then stretched by 50% to a length of 195mm, flattened to 45×150×550mm, rolled in the first pass The second pass is 40% to thickness 27mm, the second pass is 35 to thickness 17.5mm, and then rolled to 2.0mm thickness for tension rolling to 0.2mm thickness. After the finished product is annealed at 900°C for 3 hours, the elongation of the strip reaches 38%, and the grain size is 10. Grade, the mechanical properties are shown in Table 1, and the strip length is 110 meters.

[0020] Table 1 Implementation Example 1 The room temperature mechanical properties of niobium strip

[0021] Tensile strength

Embodiment 2

[0023] Three secondary smelting ingots are heated in an electric furnace at 800°C for 80 minutes, the upsetting ratio is 35% to a length of 130mm, and the length is drawn by 50% to a length of 195mm, flattened to 45×150×550mm, and the first rolling pass is 40 % to a thickness of 27mm, the second pass is 35 to a thickness of 17.5mm, and then rolled to a thickness of 2.0mm, and the three billets are butt-welded into one by argon arc welding, and then tension-rolled to a thickness of 0.2mm, and the finished product is 900°C After 3 hours of annealing, the elongation rate of the strip reaches 34%, the grain size is 10 grades, the mechanical properties are shown in Table 2, and the strip length is 298 meters.

[0024] Table 2 Implementation Example 2 The room temperature mechanical properties of the niobium strip

[0025] Tensile strength

Embodiment 3

[0027] Three secondary smelting ingots are heated in an electric furnace at 1000°C for 75 minutes, the upsetting ratio is 35% to 100mm, and then the length is 50% to 160mm, flattened to 45×160×350mm, and the first rolling pass is 40% to the thickness 27mm, 35% in the second pass to a thickness of 17.5mm, and then rolled to a thickness of 2.0mm, the three billets were butt welded into one by argon arc welding, and then tension rolled to a thickness of 0.1mm, and the finished product was annealed at 850°C for 3h The elongation rate of the final strip reaches 31%, the grain size is grade 9, the mechanical properties are shown in Table 2, and the strip length is 400 meters.

[0028] The room temperature mechanical properties of table 3 implementation example 3 niobium bands

[0029] Tensile strength

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com