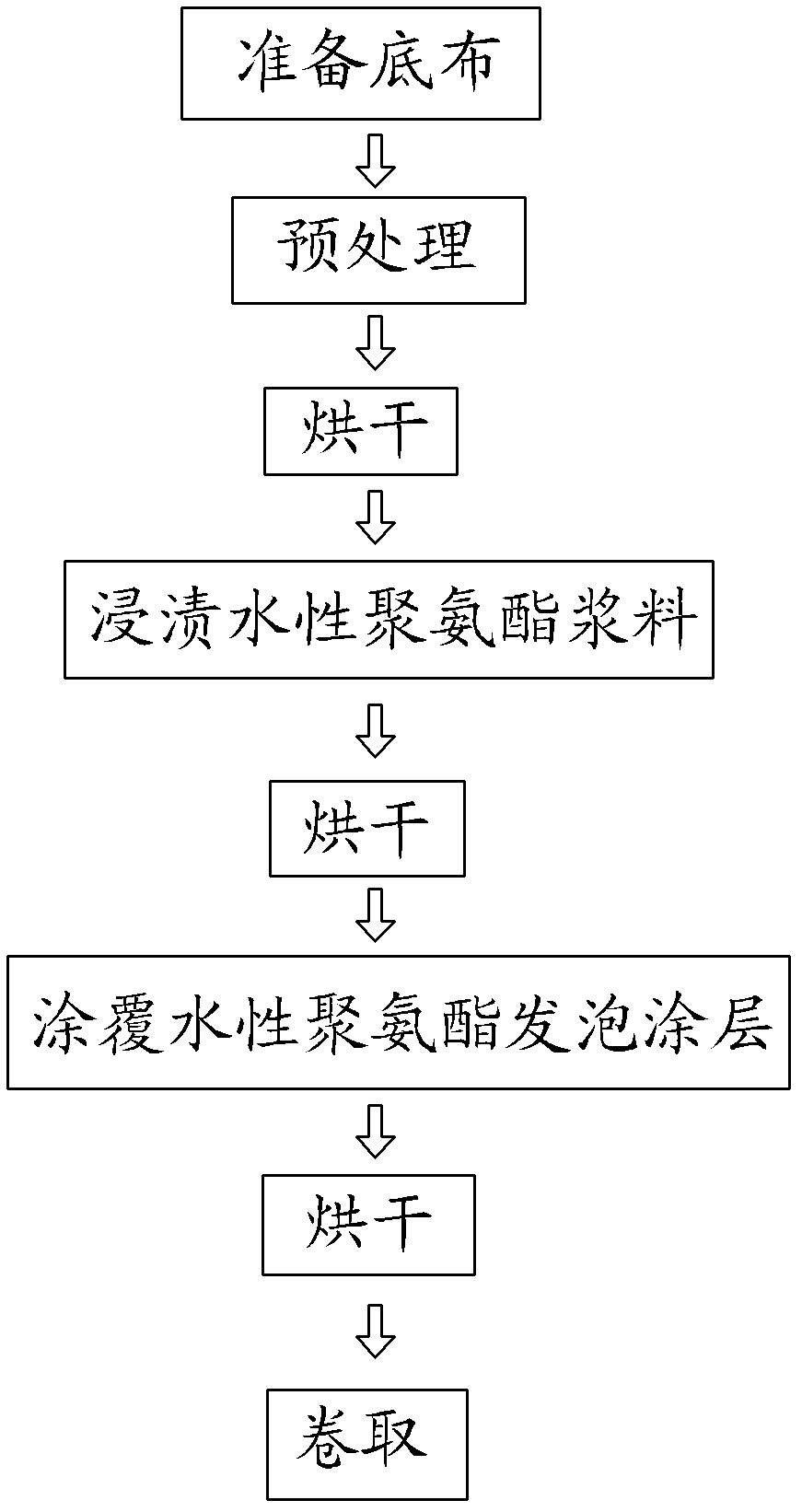

Preparation method of water-soluble polyurethane leather beth

A water-based polyurethane and synthetic leather technology, applied in the processing of textile materials, textile and papermaking, liquid/gas/steam textile material processing, etc., can solve the problems of energy consumption, environmental and personnel hazards, uneven bubbles, etc. The effect of flatness, lower production cost and lower dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

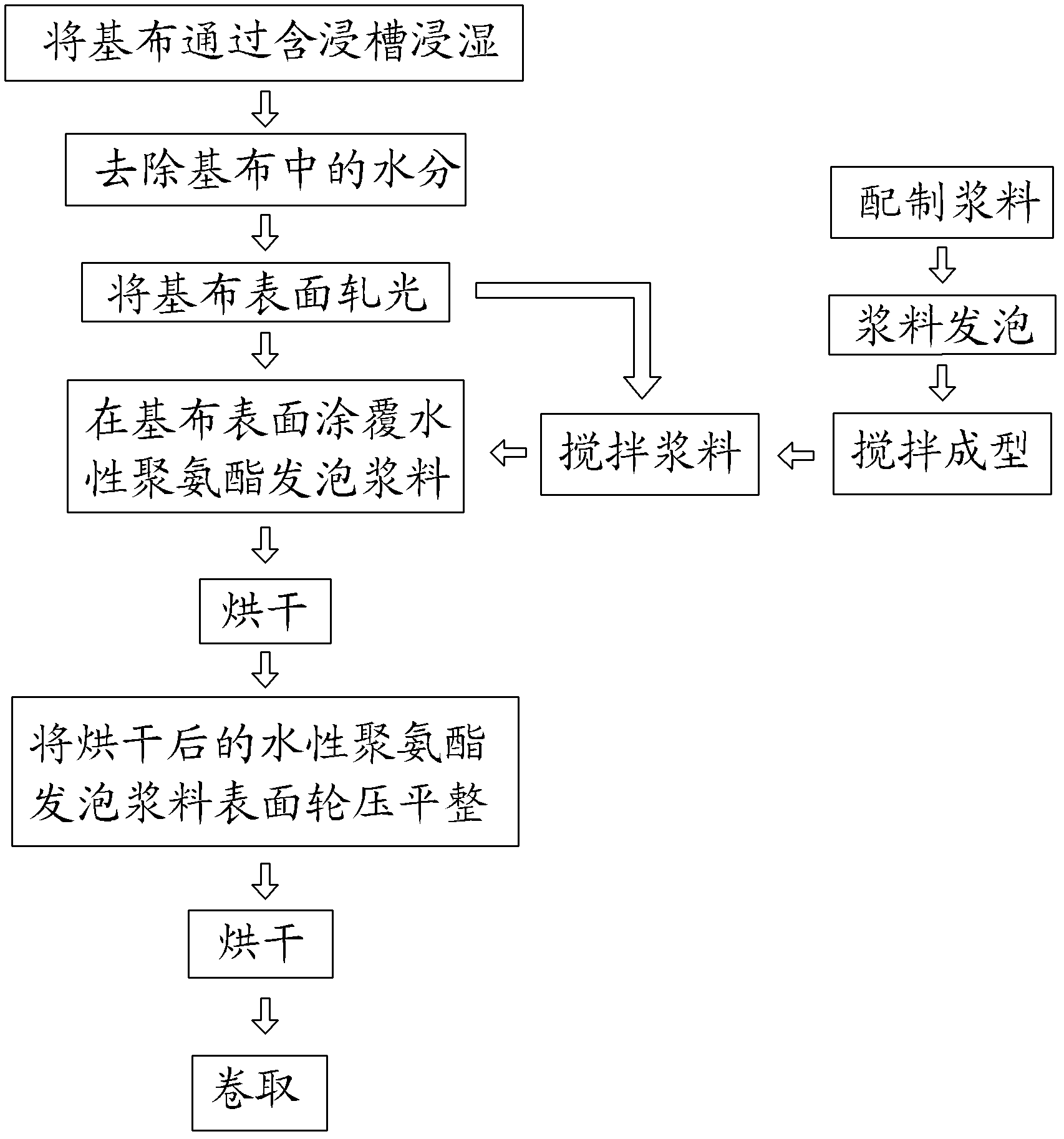

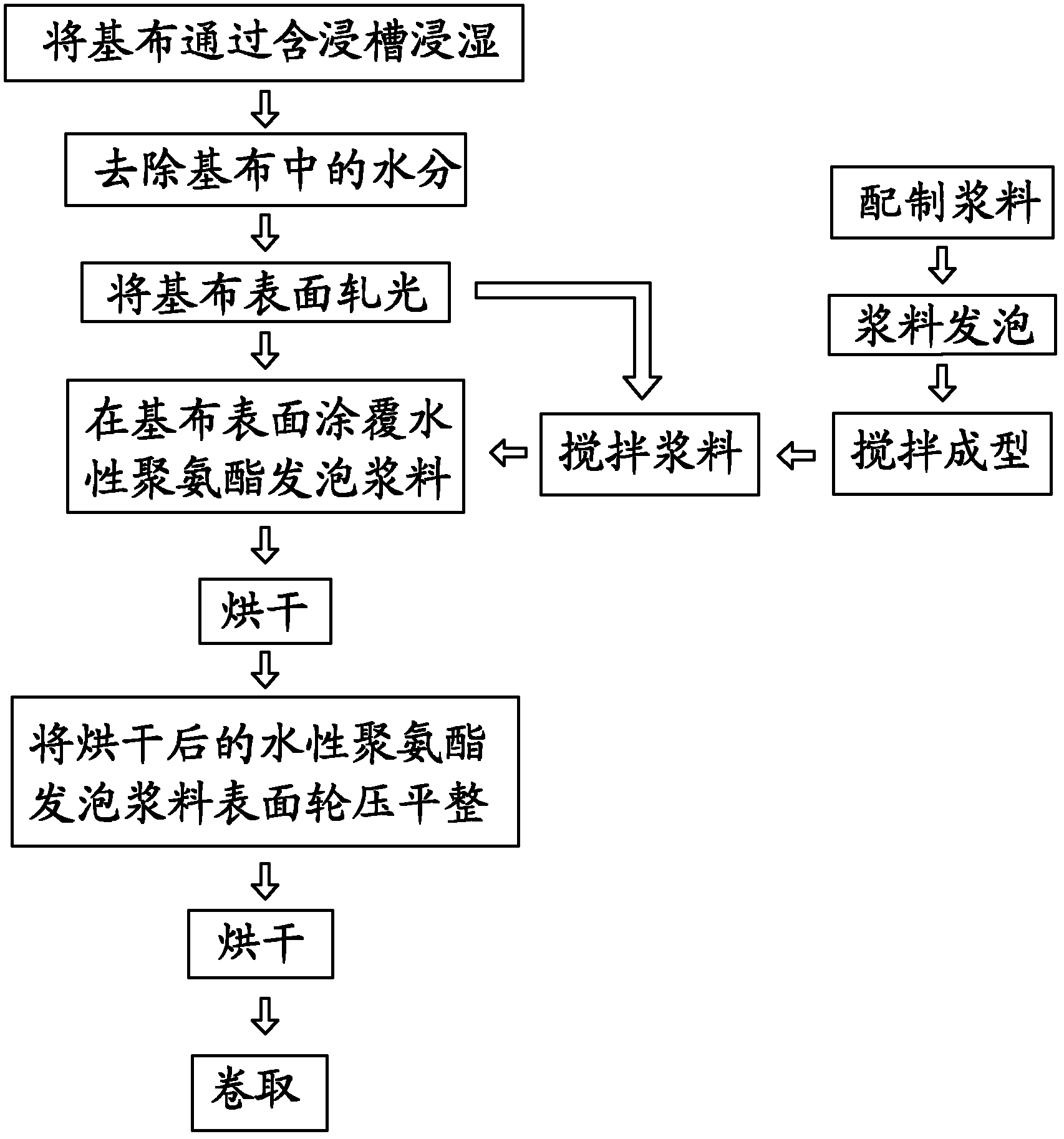

[0031] refer to figure 2 Shown, embodiment 1 of the present invention comprises the following steps successively:

[0032] Step A, soaking the base cloth;

[0033] Step B, removing moisture in the base cloth;

[0034] Step C, calendering the surface of the base cloth;

[0035] Step D, coating the water-based polyurethane foaming slurry on the surface of the base cloth;

[0036] Step E, drying;

[0037] Step F, rolling the surface of the dried water-based polyurethane foam slurry to make it smooth;

[0038] Step G, coiling.

[0039] Wherein, the step A is realized in the following manner: the base cloth is soaked through an impregnation tank, the base cloth is a kind of non-woven fabric, woven fabric or knitted fabric, preferably woven fabric or knitted fabric, and the The solution in the impregnation tank is NaCl aqueous solution with a mass concentration of 5% to 10%.

[0040] Wherein, the step B is realized in the following way: the moisture in the base cloth is sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com