Method for recycling waste polyurethane product

A polyurethane and waste technology, applied in the field of polyurethane, can solve the problems of increasing efficiency, polluting urethane foam, reducing costs, etc., and achieves the effects of increasing efficiency, improving dimensional stability, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

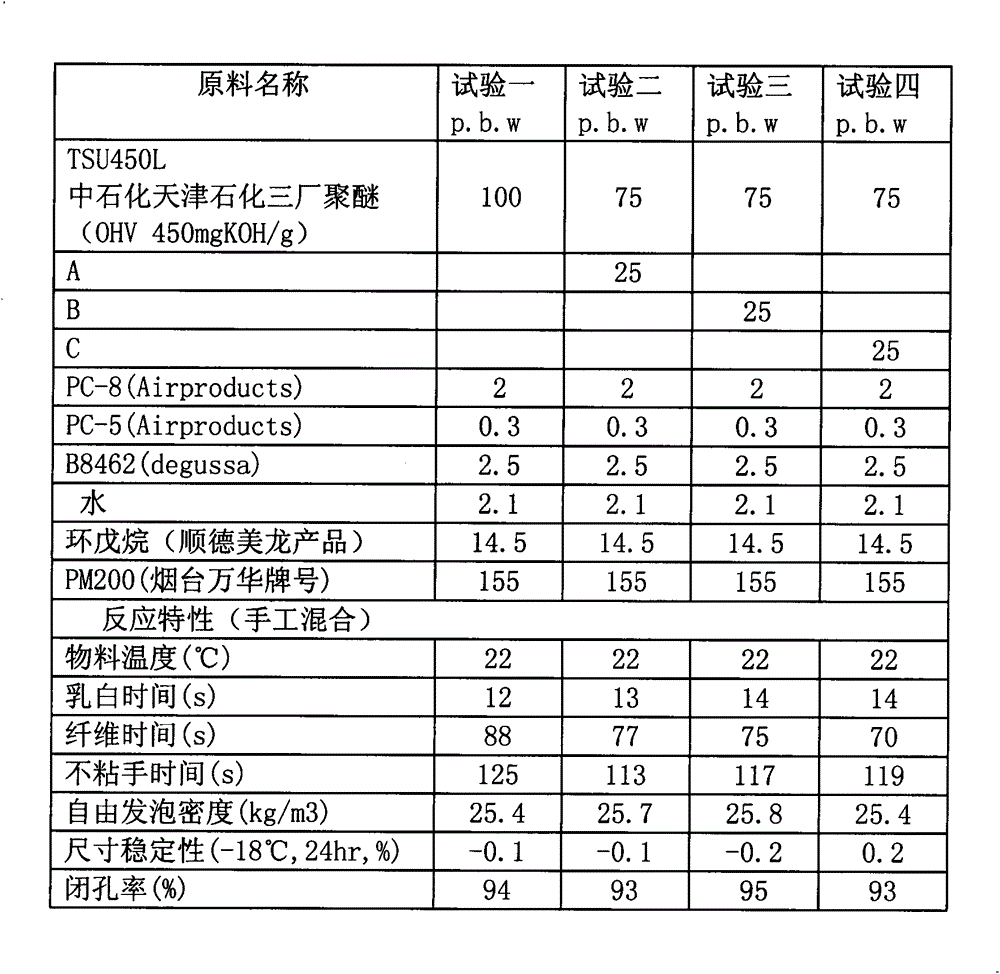

Examples

Embodiment 1

[0018] Example 1: 500 grams of diethylene glycol was added to a 1500 ml three-necked bottle with a stirring, heating and temperature control device, and 2.5 grams of potassium hydroxide was added, heated to 150-250 ° C, and then 500 grams of polyurethane waste The recyclate (rigid polyurethane foam) was cut and crushed into small pieces, slowly added to diethylene glycol, and stirred while heating. After about 12 hours, the foam was completely dissolved, and the low-molecular weight was removed in a vacuum for 20 minutes (you can also not remove the low-molecular weight). Molecule), to obtain reclaimed product A940 grams.

Embodiment 2

[0019] Embodiment 2: 900 grams of reclaimed matter obtained by the method of Example 1 are moved into the test kettle, and 900 grams of propylene oxide are passed into by the polyether polyol production method to carry out the polymerization reaction, and the reaction is finally neutralized with phosphoric acid. Get polyether polyol B1780 grams.

Embodiment 3

[0020] Embodiment 3: 900 grams of reclaimed matter obtained by the method of Example 1 was added according to the polyester polyol production method to add 600 grams of phthalic anhydride to carry out the esterification reaction to obtain polyester polyol C1400 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com