Polyurethane composite heat-insulating material for solar heat-insulating water tank

A technology of composite thermal insulation materials and thermal insulation water tanks, which is applied in the field of thermal insulation materials, can solve the problems of reducing polyurethane thermal insulation performance, non-flame retardancy, and fire, and achieve the effects of improved thermal insulation performance, excellent flame retardancy performance, and gentle response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

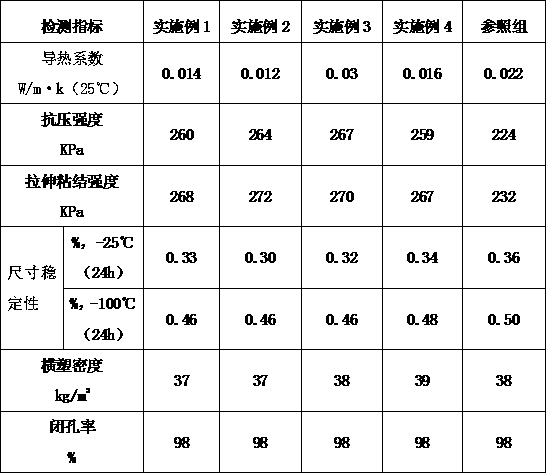

Examples

Embodiment 1

[0024] Weigh 90 parts of composite polyether polyol, 110 parts of isocyanate, 1 part of nano kaolin, 2 parts of foaming agent, 0.1 part of foam stabilizer, 0.5 part of catalyst, 0.5 part of crosslinking agent and 0.1 part of composite flame retardant according to the number of parts by mass. share.

[0025] (1) Add composite polyether polyol and nano kaolin into the reactor according to the formula ratio, adjust the rotating speed of the agitator to keep it at 2000r / min, and make it mix evenly;

[0026] (2) Add foaming agent, foam stabilizer, catalyst, crosslinking agent, composite flame retardant and appropriate amount of water into the reactor, and mix evenly with a mixer;

[0027] (3) Finally, add isocyanate into the reactor and stir to mix evenly. When the mixture in the reactor produces bubbles and the color of the foam turns white, it is immediately injected into the cavity of the solar water heater tank for foaming. After curing at high temperature, it can be obtained ...

Embodiment 2

[0029] Weigh 95 parts of composite polyether polyol, 120 parts of isocyanate, 2 parts of nano kaolin, 3 parts of foaming agent, 0.2 part of foam stabilizer, 1 part of catalyst, 0.6 part of crosslinking agent and 0.2 parts of composite flame retardant according to the number of parts by mass. share.

[0030] The preparation process is the same as in Example 1.

Embodiment 3

[0032] Weigh 98 parts of composite polyether polyol, 125 parts of isocyanate, 2.5 parts of nano kaolin, 4 parts of foaming agent, 0.4 part of foam stabilizer, 2 parts of catalyst, 0.8 part of crosslinking agent and 0.3 parts of composite flame retardant according to the number of parts by mass. share.

[0033] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com