Biodegradable foam plastic and preparation method thereof

A technology of foam plastics and biodegradation, which is applied in the field of foam plastics and its preparation, can solve the problems of strict labor protection requirements, low thermal deformation temperature, and high price, and achieves less stringent safety protection requirements, simple process equipment, and high quantum yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

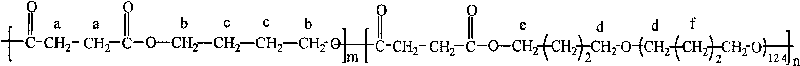

[0044] 100 parts by mass of polybutylene succinate with a molecular weight of 30,000, 1 part by mass of UV photoinitiator benzoin, 3 parts by mass of crosslinking agent trimethylolpropane trimethacrylate, 3 parts by mass of Inorganic blowing agent modified carbonate (white blowing agent TH-308), the nucleating agent nano-scale calcium carbonate of 2 mass parts, the additive of 10 mass parts (promoter zinc oxide of 5 mass parts and 5 mass parts Lubricant stearic acid) was mixed in a twin-screw extruder at 130°C for 5 minutes. After mixing evenly, it was pressed on a hot press at 150°C and 5-10 MPa for 2 minutes. After natural cooling, flakes of about 0.1 mm were obtained. Then the sheet was irradiated with a 200w medium-pressure mercury lamp for 10 minutes to obtain cross-linked polybutylene succinate with a gel content of 40.1%.

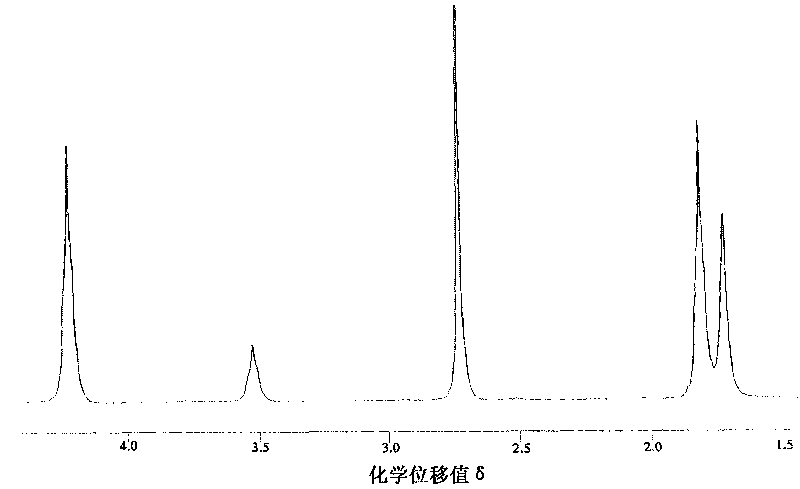

[0045] The determination of the gel content adopts the extraction method, and the specific method is as follows: put the sample after ultraviolet ir...

Embodiment 2

[0048] 100 mass parts molecular weight is 40,000 polybutylene succinate, 2 mass parts of photoinitiator α-hydroxyalkyl phenone, 7 mass parts of crosslinking agent triallyl cyanurate, 5 mass parts The foaming agent azodicarbonamide, the nucleating agent nano-scale silicon dioxide of 3 mass parts, the additive (accelerator zinc oxide) of 5 mass parts mix 10min at 140 ℃ in twin-screw extruder, after mixing uniformly , press on a hot press at 140°C, 5-10Mpa for 10min, and get a thin slice of about 0.3mm after natural cooling. Then the slice was irradiated with a 1000w medium-pressure mercury lamp for 2 minutes to obtain cross-linked polybutylene succinate with a gel content of 35.6%. The assay method of gel content is with embodiment 1.

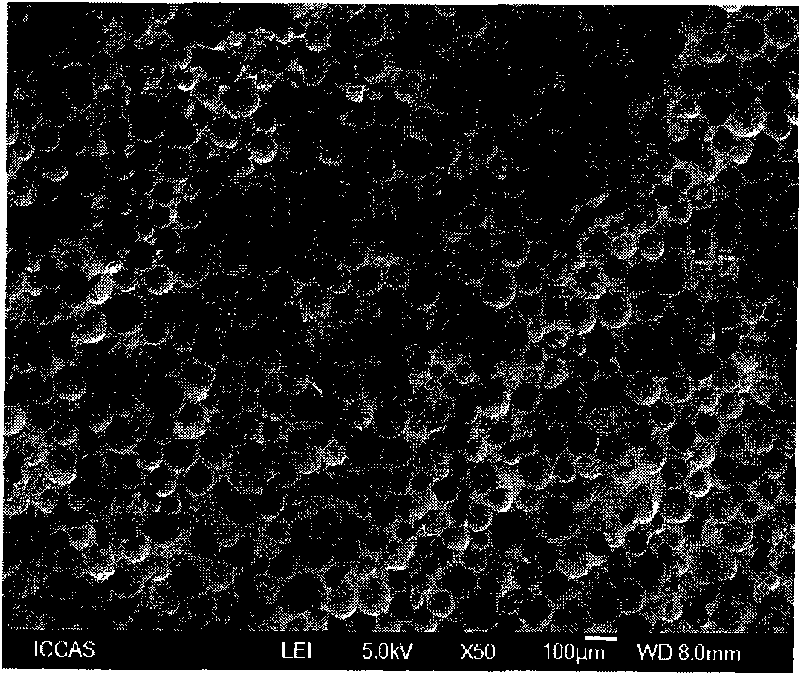

[0049] Then foam it at 180° C. for 20 minutes on a hot press to obtain a polybutylene succinate foam. The scanning electron micrograph of gained foamed plastics (see figure 1 ) shows that a uniform and fine foam structure has been obtained. T...

Embodiment 3

[0052] 100 mass parts molecular weight is 50,000 polybutylene succinate, 3 mass parts of photoinitiator dialkoxy acetophenone, 10 mass parts of crosslinking agent pentaerythyl alcohol tetramethacrylate, 7.5 mass parts of Foaming agent 4,4-disulfonylhydrazide diphenyl ether, the nucleating agent nanoscale talcum powder of 1 mass part, the additive of 5 mass parts (the lubricant stearic acid of 3 mass parts and the plasticizer of 2 mass parts Glycerin) was mixed in a twin-screw extruder at 160°C for 20min. After mixing evenly, it was pressed on a hot press at 160°C and 5-10Mpa for 5min, and a sheet of about 0.5mm was obtained after natural cooling. Then the slice was irradiated with a 400w medium-pressure mercury lamp for 5 minutes to obtain cross-linked polybutylene succinate with a gel content of 28.7%. Then foam at 210° C. for 30 minutes to obtain polybutylene succinate foam. Foam density is 159Kg / m 3 .

[0053] The enzymatic degradation test was used to characterize the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com