Ultraviolet-cured acrylic ester hot-melt pressure-sensitive adhesive and preparation method thereof

A technology of hot-melt pressure-sensitive adhesives and acrylates, which is used in the fields of adhesives, hygiene and medical products, and can solve problems such as insufficient holding force and poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

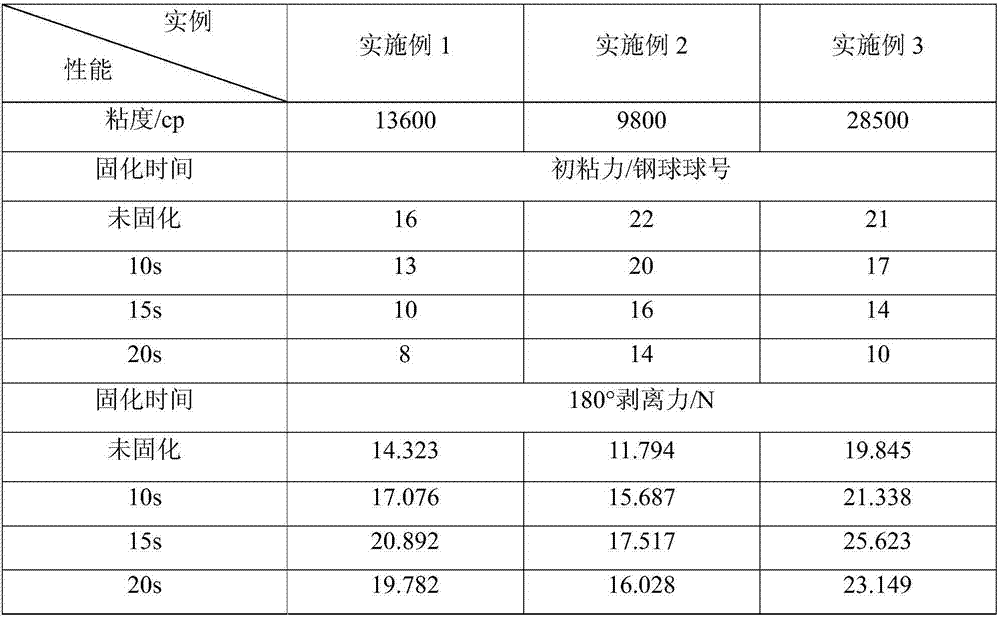

Embodiment 1

[0042] The liquid initiator tert-butyl peroxybutyrate of Akema Company is selected for use, and the input amount is 0.3wt% of the total weight of the formula. The initiator is added in batches, and ethyl acetate is used as the reaction solvent; isooctyl acrylate 72 parts of ester, 14 parts of butyl acrylate, 12 parts of methyl methacrylate, 1 part of acrylic acid, 0.15 parts of photoinitiator, 0.35 parts of defoamer A515, 0.5 parts of antioxidant 1010, and the design solid content is 50% , the reaction time is 7 hours, and the high cohesion acrylate hot-melt pressure-sensitive adhesive is obtained after removing the solvent according to the above method.

[0043] Glue coating: Coating on release paper, set the temperature of the upper roller to 130°C, the temperature of the lower roller to 100°C, the temperature of the storage tank to 130°C, control the glue amount to 40g, and the coating thickness to 3.5-4μm.

[0044] UV radiation curing: place the glue-coated release paper i...

Embodiment 2

[0049] Select the refined AIBN as the initiator, the input amount is 0.27wt% of the total weight of the formula, the initiator is added in batches, and ethyl acetate is used as the reaction solvent; 79 parts of isooctyl acrylate, 3.5 parts of butyl acrylate , 15 parts of methyl methacrylate, 1.5 parts of acrylic acid, 0.25 parts of photoinitiator, 0.35 parts of defoamer A515, 0.40 parts of antioxidant 264, the design solid content is 50%, and the reaction time is 7 hours. According to the above The high cohesion acrylate hot-melt pressure-sensitive adhesive is obtained after the solvent is removed by the method.

[0050] Glue coating, UV curing and performance testing refer to Example 1.

Embodiment 3

[0052]The refined AIBN is selected as the initiator, and the input amount is 0.2wt% of the total weight of the formula. The initiator is added in batches, and ethyl acetate is used as the reaction solvent; 70 parts of isooctyl acrylate and 5 parts of butyl acrylate , 12 parts of methyl methacrylate, 1 part of acrylic acid, 0.8 parts of Changxing polyfunctional acrylic monomer EM39, 0.20 parts of photoinitiator, 0.6 parts of defoamer A501, 0.40 parts of antioxidant 264, positive twelve 0.4 parts of mercaptan, 10 parts of liquid hydrogenated petroleum resin 1020E, designed solid content of 50%, and reaction time of 7 hours. After removing the solvent in the above-mentioned manner, a high-cohesion acrylate hot-melt pressure-sensitive adhesive was obtained.

[0053] Glue coating, UV curing and performance testing refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com