Deodorization garbage can and using method thereof

A technology for deodorizing trash cans and garbage storage, applied in trash cans, garbage collection, applications, etc., can solve problems such as single function of trash cans and odor generation, achieve good adsorption effect, prevent community environmental problems, and solve odors. Problems and Effects of Landfill Leachate Leakage Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

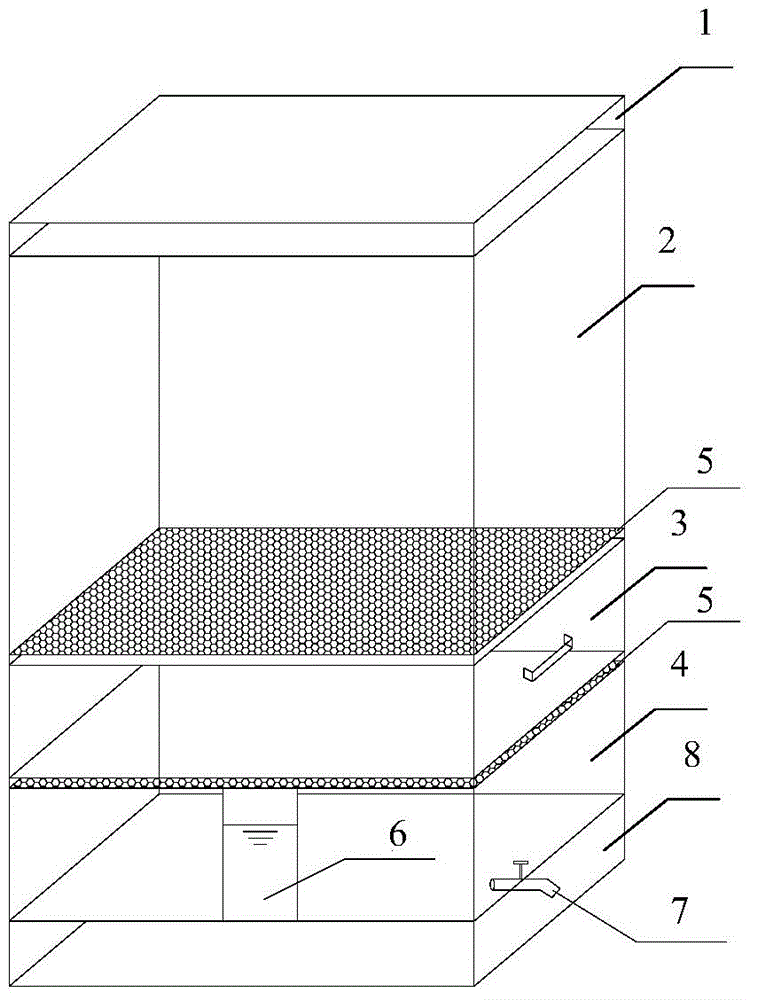

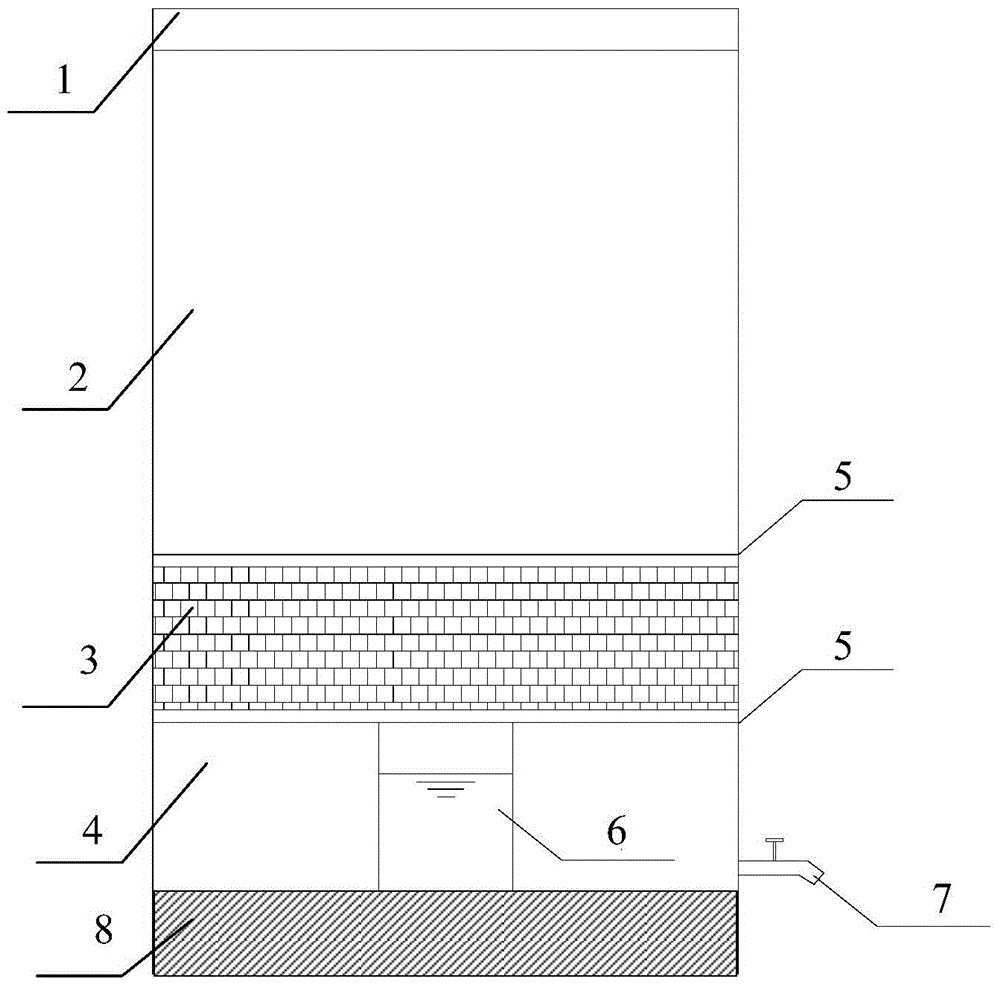

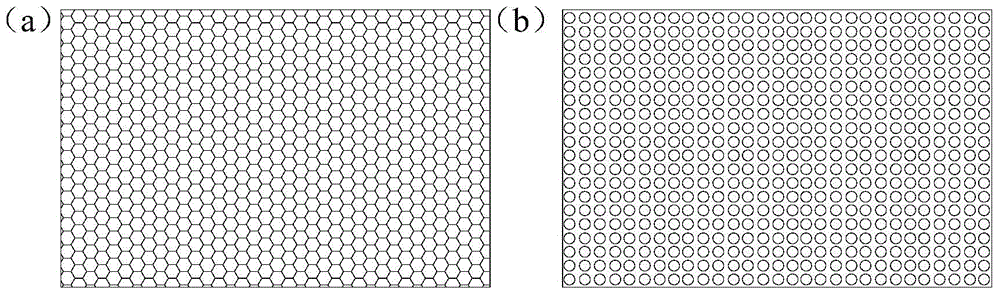

[0037]1. In this embodiment, three deodorizing garbage bins are first produced, respectively labeled No. 1, No. 2, and No. 3. The height ratios of the garbage storage layer, drawer-type packing layer and garbage leachate collection layer are 80cm, 10cm, 10cm, that is, the height ratio is 8:1:1,

[0038] 2. Then, according to the following mass ratio, pass the raw materials through a 100-mesh sieve and mix them directly to obtain a compounded composite filter material:

[0039] Composite filter material 1: 30 parts of zeolite, 20 parts of natural goethite, 20 parts of activated carbon, 20 parts of biological carbon powder (purchased from Yixing Fuxing filter material factory, the same below), 10 parts of lime.

[0040] Composite filter material 2: 20 parts of zeolite, 30 parts of natural goethite, 20 parts of activated carbon, 20 parts of biological carbon powder, and 10 parts of lime.

[0041] 3. There is no filter material in the No. 1 trash can, the composite filter materia...

Embodiment 2

[0054] 1. In this example, firstly make three deodorant trash bins identical to those in Example 1, respectively labeled No. 1, No. 2, and No. 3; and then pass the raw materials through a 100-mesh sieve according to the following mass ratio Mix evenly directly to get compound composite filter material.

[0055] Composite filter material 3: 35 parts of zeolite, 25 parts of limonite, 10 parts of activated carbon, 15 parts of biochar, and 15 parts of lime.

[0056] Composite filter material 4: 40 parts of zeolite, 30 parts of limonite, 5 parts of activated carbon, 10 parts of biochar, and 15 parts of lime.

[0057] 2. There is no filter material in the No. 1 trash can, the composite filter material 3 is filled in the No. 2 trash can, and the composite filter material 4 is filled in the No. 3 trash can. Add garbage of the same composition to the three trash cans, including 32.4g of biomass waste and 500g of kitchen waste, and the biomass should be shredded and mixed with the kitc...

Embodiment 3

[0062] 1. In this example, three deodorizing garbage bins are first produced, which are the same as in Example 1, and are respectively marked as No. 1, No. 2, and No. 3; no filter material is installed in the No. Composite filter material 4 is filled in No. 3 and No. 3 garbage bins. Add garbage of the same composition to the three trash cans, including 32.4g of biomass waste and 500g of kitchen waste, and the biomass should be shredded and mixed with the kitchen waste. For 5 consecutive days, replace the garbage every day without changing the filter material. The ambient temperature of the trash can is a constant temperature heating of 35°C.

[0063] 2. Observe the leachate output in the lower space of the trash can every day. Experimental results such as Figure 4 shown.

[0064] It simulates the replacement of garbage every day in daily life without changing the filter material. Since the garbage is replaced every day, the daily output of leachate will be relatively les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com