Siloxane-group light-initiated polyacrylic ester/silicon dioxide nanometer material and preparation method thereof

An acrylate and silica technology, applied in the direction of coating, can solve the problems of time-consuming and energy-consuming, unfavorable industrialization, unsolved or improved migration of small molecular photoinitiators, etc., and achieves environmental friendliness, easy industrial application, Effectiveness in solving toxicity and odor problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

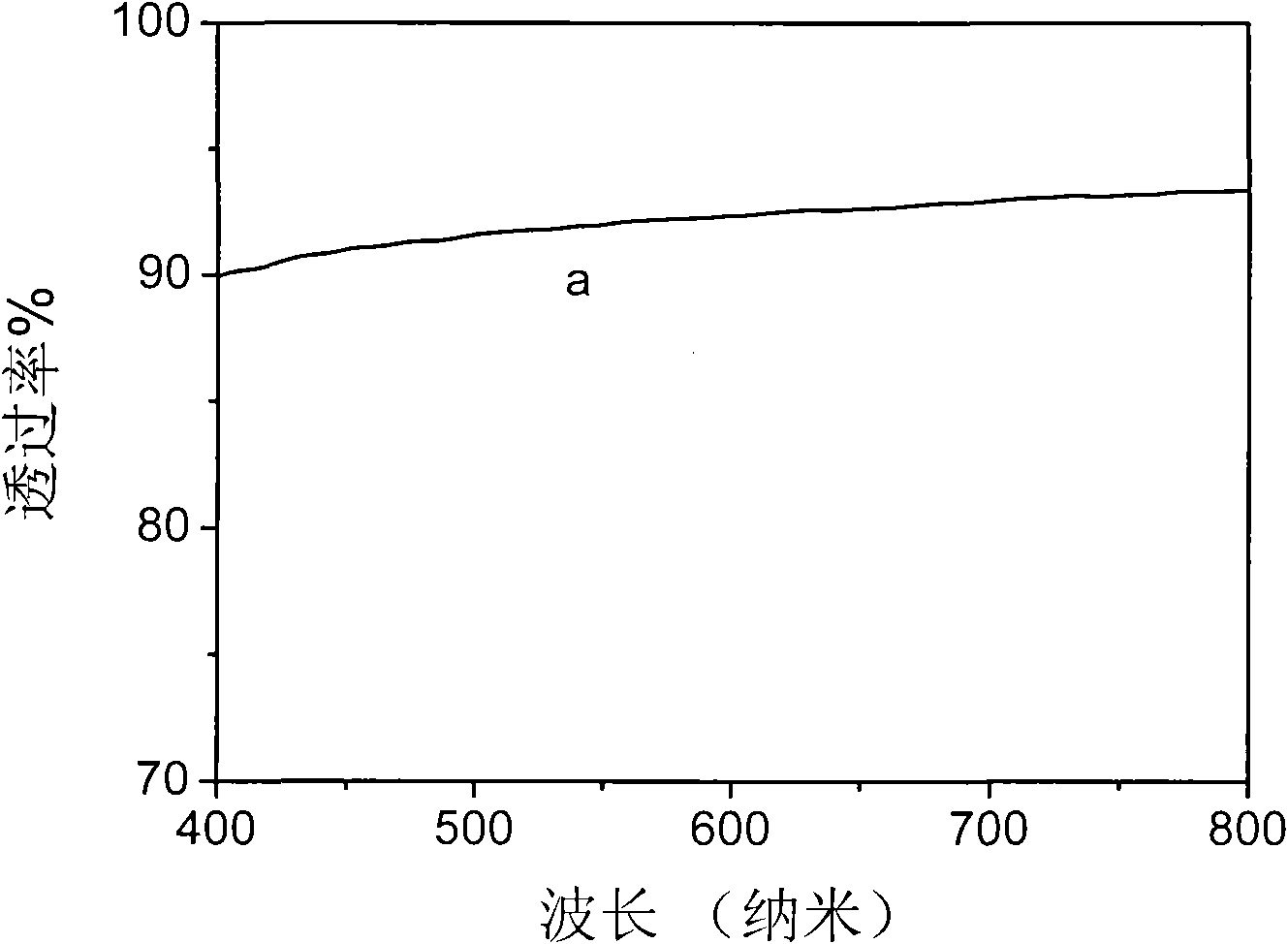

Embodiment 1

[0030] 20.8g (0.1mol) of tetraethyl orthosilicate (TEOS), 5.4g (0.3mol) of water and 0.05g of hydrochloric acid were added to 23.75g of ethanol, and the mixture was subjected to hydrolysis and condensation at room temperature and a stirring speed of 300rpm After 4 hours, tetraethyl orthosilicate prepolymer was obtained;

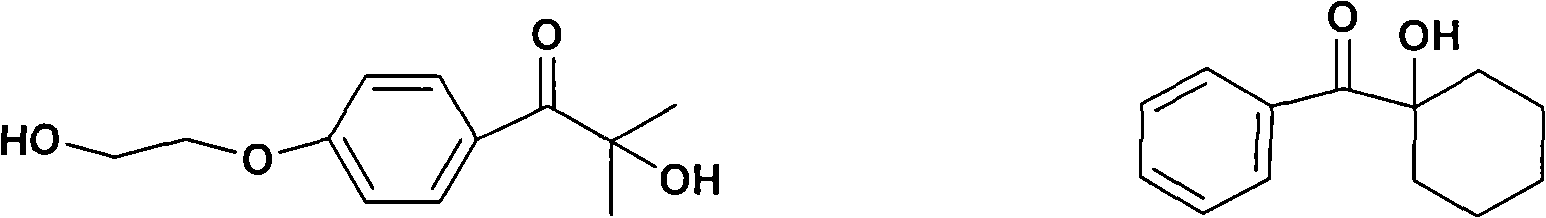

[0031]Add 0.20mol 2-hydroxy-4'-(2-hydroxyethoxy)-2-methyl-1-phenylacetone-1 (manufactured by Ciba, product name Irgacure 2959), 0.22mol mercapto Acetic acid, 150mL toluene and 0.5% 4-dimethylaminopyridine p-toluenesulfonate by weight of Irgacure2959 were refluxed at 120°C for 12 hours to obtain 0.184mol of photoinitiator with mercapto groups; the above process can be represented by the reaction formula for:

[0032]

[0033] Take again 0.184mol of photoinitiator with mercapto, 0.184mol γ-glycidyl etheroxypropyl trimethoxysilane (Chinese Academy of Sciences, product name KH560), 60mL of dichloromethane and 0.5% triethylamine by weight of KH560 Add it into...

Embodiment 2

[0042] 10.4g (0.05mol) of tetraethyl orthosilicate (TEOS), 1.8g (0.1mol) of water, 0.075g of hydrochloric acid were added to 37.73g of ethanol, and the mixture was hydrolyzed at room temperature and at a stirring speed of 500rpm Condensate for 2 hours to obtain a prepolymer of tetraethyl orthosilicate;

[0043] In the 250mL there-necked flask, add 0.20mol1-hydroxyl-cyclohexyl benzophenone (produced by Ciba Company, product name Irgacure184), 0.21mol2-mercaptopropionic acid, 110mL toluene and 0.3% methanesulfonic acid by Irgacure 184 weight, at 125 Reflux at ℃ for 20 hours to obtain 0.182mol of photoinitiator with mercapto;

[0044] Take 0.182mol of photoinitiator with mercapto group, 0.182mol γ-glycidyl ether oxypropyl trimethoxysilane, 75mL dichloromethane and 0.3% of γ-glycidyl ether oxypropyl trimethoxysilane weight Sodium carbonate was added in a 150mL three-necked flask, and reacted for 24 hours under nitrogen protection and room temperature, and the solvent was removed ...

Embodiment 3

[0048] 15g (0.072mol) tetraethyl orthosilicate (TEOS), 1.29g (0.072mol) water, 0.04g hydrochloric acid were added to 33.67g ethanol, and the mixture was subjected to hydrolysis and condensation at room temperature and a stirring speed of 400rpm After 5 hours, tetraethyl orthosilicate prepolymer was obtained;

[0049] Add 0.20mol α-hydroxybenzoin methyl ether, 0.23mol 2-mercaptobutyric acid, 170mL p-xylene and 0.8% p-toluenesulfonic acid by α-hydroxybenzoin methyl ether weight in 250mL there-necked flask, at 130 Reflux for 24 hours at °C to obtain 0.18mol of photoinitiator with mercapto groups;

[0050] Then take 0.18mol of photoinitiator with mercapto, 0.18mol of γ-methacryloxypropyltrimethoxysilane, 55mL of dichloromethane and γ-methacryloxypropyltrimethoxy 0.8% potassium carbonate of silane weight was added in a 150mL three-necked flask, reacted for 24 hours under nitrogen protection and room temperature, and the solvent was removed to obtain 0.18mol of difunctional photoin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com